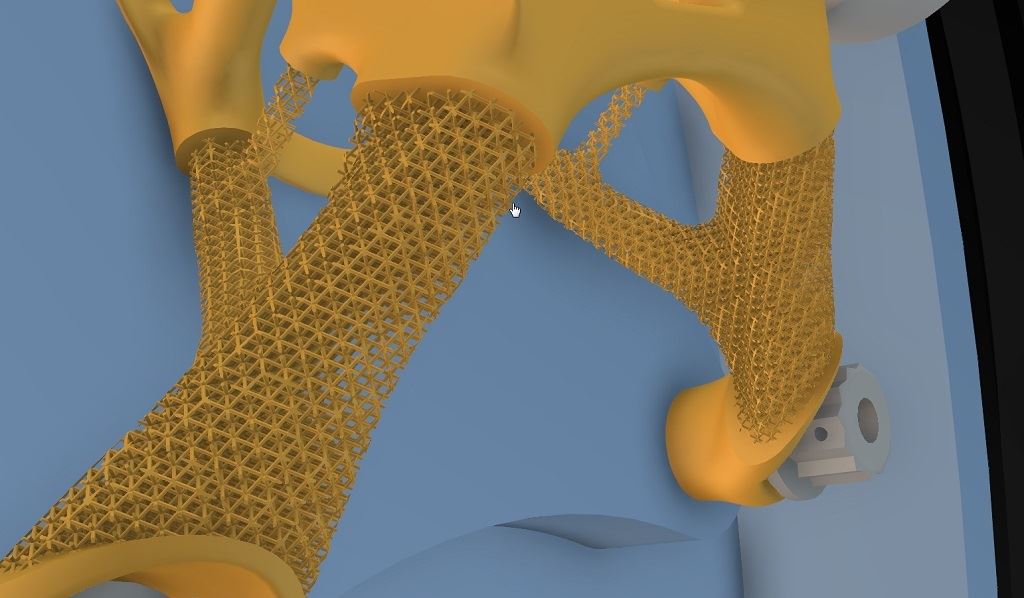

![Additive manufacturing can produce parts using geometry that is not possible through traditional subtractive manufacturing, such as lattice structures for optimized strength and weight. [Image: Dassault Systèmes]](https://fabbaloo.com/wp-content/uploads/2020/05/Latticea_img_5eb09094d1549.jpg) Additive manufacturing can produce parts using geometry that is not possible through traditional subtractive manufacturing, such as lattice structures for optimized strength and weight. [Image: Dassault Systèmes]

Additive manufacturing can produce parts using geometry that is not possible through traditional subtractive manufacturing, such as lattice structures for optimized strength and weight. [Image: Dassault Systèmes]

Additive manufacturing promises to make aircraft fly higher, faster, and more fuel-efficiently than ever before.

This is the second of a two-part discussion in accelerating aerospace with additive manufacturing: read part one here.

Let’s Do This Thing

First things first. If you’re a newbie to additive manufacturing, you might be wondering how it all works. A variety of 3D printing technologies exist, but most end-use parts production is done using some form of powder bed fusion. With metal parts, this is known as DMLS (direct metal laser sintering), SLM (selective laser melting), DMP (direct metal printing), and other brand-specific acronyms. Polymer parts are made using SLS (selective laser sintering) and SHS (selective heat sintering), to name a few.

All work in a similar manner, using a laser to fuse, melt, or sinter individual particles of metal or plastic powder, building parts one paper-thin layer at a time from the bottom up. On the metal side, materials range from the titanium and superalloys already mentioned to aluminum, tool steel, bronze, and stainless steel. Powder bed polymers include polystyrenes, nylons, polycarbonate, and super-strong PAEK (polyaryletherketones).

This is a simplified view of the process. There are dozens of other 3D printing hardware brands and techniques available to aerospace product designers. Some other techniques include: jetting, extrusion, photocuring, and deposition. A number of techniques produce both prototype and low- to mid-volume part production using aerospace-grade materials. In each of the examples listed at the beginning of this article, however, some form of powder bed fusion printing is involved.

Opening the Toolbox

Taking advantage of additive manufacturing’s design freedom requires the right software and creativity, and additive manufacturing offers a new range of possibilities. Dassault Systèmes, for example, developed an entire suite of products designed to support the digital thread associated with additive manufacturing.

Automating part of the additive manufacturing design process is now possible with function-driven generative design. Other capabilities include virtualization and simulation of the 3D printing process, failure prediction, finite element analysis (FEA), and much more. Each competency targets a specific aspect of this relatively novel yet extremely robust manufacturing technology.

It’s worth noting that parts do not come out of a 3D printer ready for installation in an airplane, satellite, or spacefaring vessel. Practically all 3D printed parts require a trip to the machine shop for bead-blasting, support removal, and secondary operations to complete critical part features. In fact, these subtractive manufacturing processes enjoy a synergistic relationship with the additive world, one that enhances each. Legacy manufacturing, it seems, isn’t going away anytime soon.

Ready to implement additive manufacturing, but not able to invest millions of dollars in 3D printing equipment and the people to operate it? The price tag is high for 3D printed metal parts. (End-use polymer printers are less expensive, but not by a whole lot.) A good option is to tap into the hundreds of qualified service bureaus and additive-capable machine shops, allowing you to collaborate and outsource your next 3D printed aerospace project.

Get Shopping

![Simulation is a crucial step for validating parts used in final production. [Image: Dassault Systèmes]](https://fabbaloo.com/wp-content/uploads/2020/05/Joiner_Validationa_img_5eb090956ce9d.jpg) Simulation is a crucial step for validating parts used in final production. [Image: Dassault Systèmes]

Simulation is a crucial step for validating parts used in final production. [Image: Dassault Systèmes]

Finding an additive manufacturing shop to work with can be a daunting task. This is why Dassault Systèmes developed the 3DEXPERIENCE Marketplace. Described by the company as “the largest factory in the world,” this ecosystem of industrial suppliers gives designers and engineers the ability to upload a part model, get a quote, and order parts quickly (even ones that aren’t 3D printed).

There’s also an online library of 3D components available, making the Marketplace a one-stop shop for designers, procurement people, and anyone that needs an easy way to source manufactured products. If you’re ready to give 3D printing a try, this is an excellent place to get your feet wet, and do so with minimum hassle and expense.

Wheels-Up

Additive manufacturing is poised to transform nearly every industry in our economy, and offers the aerospace and defense industry many advantages. Lower fuel costs resulting from light-weighting 3D printed parts positively impact airline profit margins. Suppliers will reap the benefits of lower manufacturing costs. And, improved operations and maintenance processes will benefit many across the industry. It’s an exciting time for aerospace. More change is on the horizon.