RepRap Ltd, the 3D printing research firm founded in 2009 by RepRap champion Adrian Bowyer, is working on a new type of fabrication method using “assembly robots”.

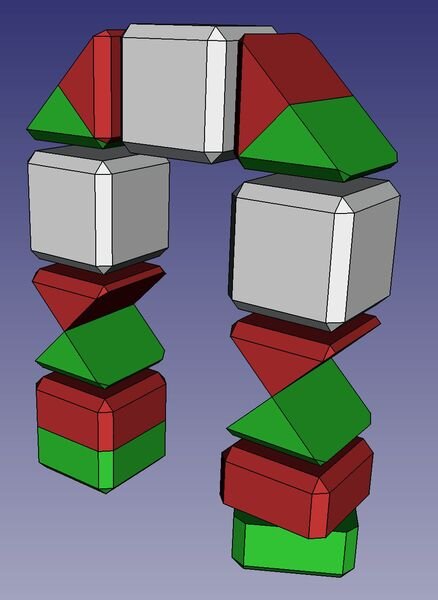

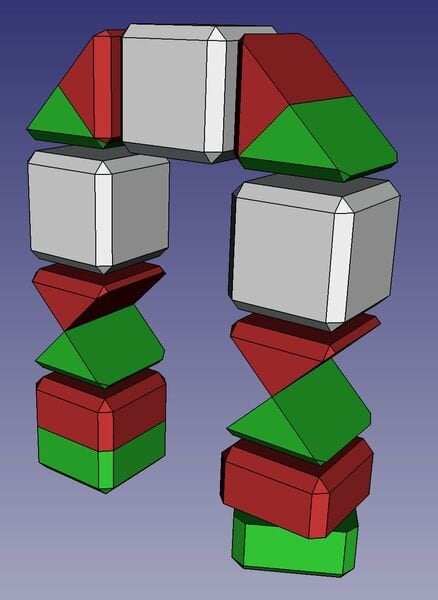

They’ve taken a cue from work done at MIT, where a type of assembly robot was developed earlier this year. The custom-made robots were able to coordinate activities to assemble arbitrary structures made from a collection of identical blocks.

![MIT assembly robots [Source: MIT]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb08c4837ebb.gif)

This was a powerful demonstration of the “swarm” approach to fabricating an object: instead of a single tool head depositing material, a large collection of robots deposits material block-by-block in the required pattern. As this approach matures and is eventually miniaturized, it could be come a standard method for producing objects.

However, RepRap Ltd has some very intriguing ideas for improving the concept. They have three ideas:

-

Have electric power and signals running through the blocks and connecting at each face. The robot could then pick up power and instructions from these and not need to be self powered.

-

Have two attachment mechanisms: magnets, to allow blocks to be attached and later removed to be placed elsewhere; and glue to produce a hard permanent high-strength join between the blocks. The glue could be applied by the building robot when a block was in its final destination position.

-

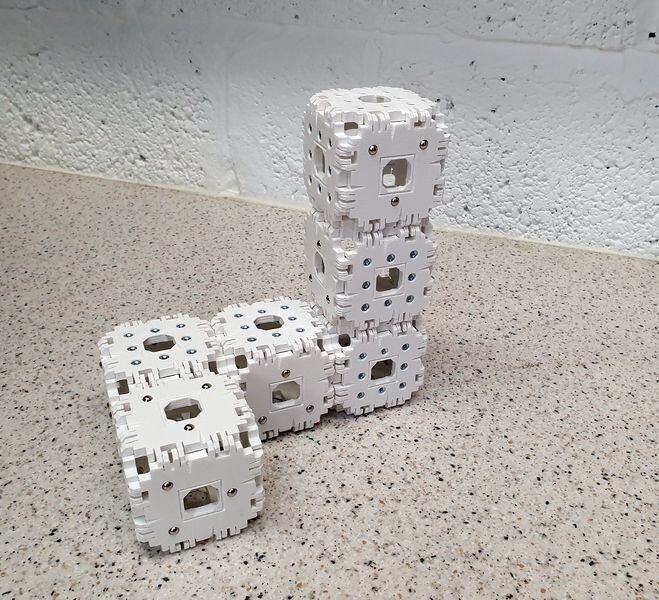

Have the robot made out of blocks that are geometrically congruent to the blocks that it is building with. These robot blocks would be active. There would be two kinds of active block: the first would be able to rotate about one mid-plane of the block and the second would be able to rotate about one axis through the middle of a pair of opposite faces.

These changes could improve the robotic assembly capability by enabling easier methods of producing complex geometries through the use of “support blocks”, as well as a more general ability to scale the system through the power distribution concept.

It seems that RepRap Ltd is literally designing and building a new robotic system around these concepts, and they’ve already produced some of the initial components, as seen here:

This is an ambitious project, as the robots will not only have to employ sophisticated coordination software, but also include a clean glue distribution system. I’m not sure how the power distribution will work, as it could get more complex depending on the size of the object and number of robots involved.

Nevertheless, it will be fascinating to see how this project plays out. If successful, it could lead to more advanced versions of the concept that may eventually lead to a revolution in building capabilities.

Via RepRap Ltd