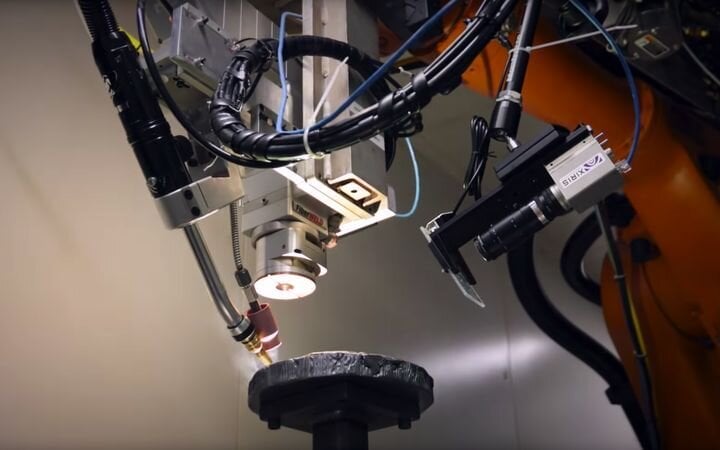

![Tool head on ADDere’s metal 3D printer [Source: ADDere]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb08c025d4ec.jpg)

ADDere is a division of Midwest Engineered Systems, a manufacturing company with a speciality in attempting unusual projects.

The company, which began in 1991, now operates some 4,000 making machines worldwide and offers a variety of manufacturing services to industry. One of the more recent additions to their services is additive manufacturing.

ADDere Development

However, unlike many service providers who simply choose a 3D printer system from a vendor and operate it, Midwest Engineered Systems in 2017 decided to build their own 3D printer. They believed the existing options to be too expensive, too small and too slow to fit with their customer base.

Midwest Engineering Services created a new division called “ADDere” to handle the development and operation of this technology.

The result was a “Laser Wire Additive Manufacturing” system. Basically a metal wire is fed to a tool head where a powerful laser swiftly melts it. As the tool head is moved around by the attached Kuka robot arm, the deposition quickly cools and solidifies. 3D objects can be built very quickly in this manner.

ADDere Print Speed

How fast can objects be produced? ADDere says their equipment can deposit metal at an incredible rate, ranging from 3kg up to 10kg per hour! To put this in perspective, a competing company, Aurora Labs, seeks to develop a machine that can 3D print 1,000kg of metal in a single day. It seems, however, that ADDere’s system can already 3D print 240kg per day.

How do they achieve this speed? They seem to have two secrets: one is to pre-heat the metal wire before it enters the tool head. This reduces the amount of energy required to melt the wire during deposition, and thus enables the wire to be pushed at a faster rate.

As an example, you can see this 55kg block of titanium, which was 3D printed in only six hours!

![55kg titanium block 3D printed using Laser Metal Wire additive manufacturing [Source: ADDere]](https://fabbaloo.com/wp-content/uploads/2020/05/ADDereTestblockwithHand_img_5eb08c0285848.jpg)

The second secret is that the machine is closed loop; all important factors are monitored and adjusted in real time to ensure the prints are of the highest possible quality.

ADDere Specifications

There are three ADDere systems listed:

-

SYSTEM I, build volume 1 x 1 x 0.5 m

-

SYSTEM II build volume 0.5 x 0.5 x 1.25 m

-

SYSTEM III build volume 40 x 8 x 2 m (!)

Yes, those numbers are meters. And yes, the SYSTEM III can literally 3D print metal objects up to 40m in length. It’s possible to put a Kuka robot system on a rail and move it along a build volume to achieve this. They say they are able to literally 3D print an entire airplane wing if required.

ADDere Advantages

There’s another advantage to this process, and that is the cost of materials. As most readers know, the cost of metal powder for use in 3D printers can be quite expensive due to the process required to manufacture it. However, the ADDere system uses only standard metal wire that is commercially available everywhere, which can be as much as half the price of powder.

For larger prints the ability to produce them using additive manufacturing could be quite advantageous due to the achievable speed. Using conventional making processes to build larger parts could be quite lengthy in duration, but a 3D print simply proceeds until it’s done. Sometimes in hours, as above, or mere days for larger parts.

Coarse Metal Surface

You’ll note that the prints obtained using this process have very coarse surfaces, which would normally be unacceptable for small 3D prints. But ADDere is targeting very large metal 3D prints where such surfaces are usually not of interest, and where the coarseness visually disappears into the larger structure.

However, in cases where surfaces, or portions of surfaces must be smooth, Midwest Engineered Systems has plenty of CNC equipment to provide that capability.

If you’re seeking an extremely large metal 3D print, you might want to check out ADDere’s options. They say the price of the systems depends significantly on the nature of the customer requirements, so for pricing it’s best to speak directly with them.

Via ADDere