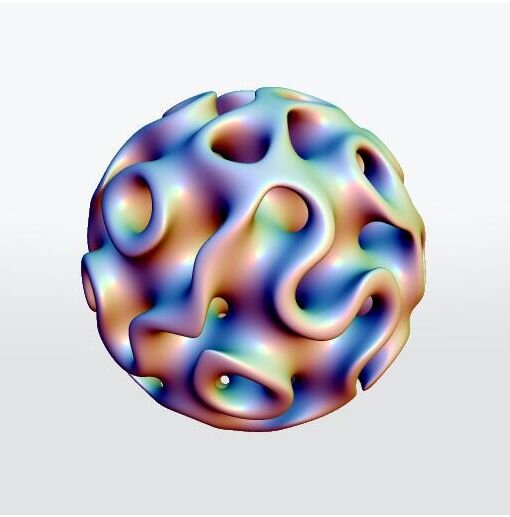

![Gyroid 3D view produced by Shapeways’ ShapeJS [Source: Shapeways]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0505bf40b9.jpg)

I’m reading an interesting post that describes some of the inner workings of Shapeways.

Matt Boyle is the VP of Engineering at Shapeways, and a recent post from him on the StackOverflow blog seems to reveal some of the methods the company uses to provide high-speed, global 3D print services.

Shapeways History

Shapeways has been one of the longest-running 3D print services available to the public. They launched in the Netherlands long ago, even before the advent of desktop 3D printing when the patents started expiring in 2009. Their initial strategy was to allow consumers to request printed parts instead of attempting to operate complex 3D printers themselves.

Over time Shapeways introduced “stores” for artists to market their designs, and thus drive more 3D printing activity for their back end infrastructure. However, as the consumer 3D printing craze ebbed, Shapeways has more recently been focusing on industrial 3D printing applications, although still supporting their original consumer base.

I visited Shapeways’ Brooklyn site in 2013, but it’s likely changed significantly since then. Probably I should arrange for another visit.

That visit revealed the secrets behind Shapeways, which included the revelation that submitted 3D models are often unprintable and had to be inspected by humans and sometimes sent back to the requestor for redesign.

Today’s Shapeways

Boyle explains three steps are taken upon job submission, validation, pricing and repair:

“Model validation services are charged with validating that the model can be printed in the first place. These checks make sure that the file is valid, that we can process it, and that the model is manifold—water-tight. Pricing calculation services are responsible for generating pricing components of our models, including but not limited to volume, part count, and surface area. Finally, fixing services help us repair our customer models and ensure that they’re printable. This includes steps like repairing meshes, decimating models to reduce triangle counts, and fixing inverted matrices on the model.”

It seems that Shapeways has optimized this process through cloud automation. They developed a kind of “pipeline” through which the countless requests flow through these steps toward production. Boyle adds:

“Once we implemented these services, we had to string them together into what we call a Model Processing Pipeline. This pipeline is a chain of the services described above that takes in a 3D file at the start and outputs a fully priced, printable, rendered 3D Model on Shapeways.com. We defined these pipelines in another service called the Director, which is effectively a directed acyclic graph of model processing services.”

This happens automatically and the result is displayed in 3D for the requestor. However, Boyle explains that typical web-based 3D viewers require the entirety of the 3D model to be passed along, which could provide an opening for the bad guys to intercept the 3D model and copy it. To counteract this threat, Shapeways had to design their own safe 3D viewer, using a new tool they designed called ShapeJS.

Shapeways Production

Boyle reveals the size of current Shapeways operations:

“Shapeways has two 3D printing facilities running around 80 machines in total, a supply chain network of over 70 production partners for overflow and special materials, and a global distribution footprint. We process over 10,000 individual (and often unique) parts through our system on a daily basis. In order to coordinate all of this activity, we’ve built an Enterprise Resource Planning (or ERP) tool, Inshape, from the ground-up, focused on the unique challenges presented by 3D printing.”

It seems that Shapeways also built their own specialized “packaging program”. This is a system that accepts a series of customer 3D models and “packs” them into the build volume of the industrial 3D printers used by the company. This is a very important technology because it allows each print run to maximize revenue by getting as many customer requests into each job.

This is a non-trivial problem, as Shapeways has the problem of mixing customer parts within the same job. Tiny parts, for example, could easily be confused with others. Thus one solution I saw during my visit was the creation of temporary “cages” that would hold a group of parts together. These would be 3D printed and then discarded after the parts group was removed.

The business of a 3D printing service is now highly complex, and to make it most profitable, much must be automated. It seems that Shapeways has done so.

Via StackOverflow