![Second trial, a more complex geometry. The part contains some inner channels made of copper [Image: Aerosint]](https://fabbaloo.com/wp-content/uploads/2020/05/6multimetal-6_img_5eb0505b0be37.jpg)

Aerosint and Aconity have proven out their work in multi-metal powder deposition 3D printing.

The success was revealed last week with increasingly complex parts created with Aerosint’s recoater used on the Aconity Midi+ system.

The two companies have been working together for some time; last year we spoke with executives from Aerosint and Aconity about the ongoing development from their collaboration. Now they have highlighted what they are heralding as “a major breakthrough for 3D printing.”

First, a look at the process — “Powder deposition realized with Aerosint’s technology followed by the laser melting” — in this video:

Shown here is a series of cubes 3D printed in a copper alloy and in steel.

Multi-Metal Powder Bed 3D Printing

Following this success, the teams progressed toward a more complex geometry: a 316 L part containing inner channels made of CuCrZr copper. With a height of 6.9mm and a 55mm diameter, the piece has copper inner channels with a 1.7mm diameter. Layer height on the part is 40 microns, and the 174-layer print took about 5:40 to print on the Aconity Midi+ L-PBF 3D printer with Aerosint’s dual-metal recoater.

![Second trial, a more complex geometry. The part contains some inner channels made of copper [Image: Aerosint]](https://fabbaloo.com/wp-content/uploads/2020/05/1multimetal-1-1_img_5eb0505b3e622.jpg)

We spoke with the team at Belgium-based Aerosint for more detail on the accomplishment. Technical Director Matthias Hick tells us:

“This multi-metal part is a huge achievement for my team and myself, as it validates the whole printing process chain we were working on the last 5 years. The technological gap for achieving this piece was quite high, so that it has been frustrating sometimes to not have been able to convince people about the disrupting potential of this technology without tangible results. Aerosint was maybe a bit too weird to be true…”

Aerosint and Aconity

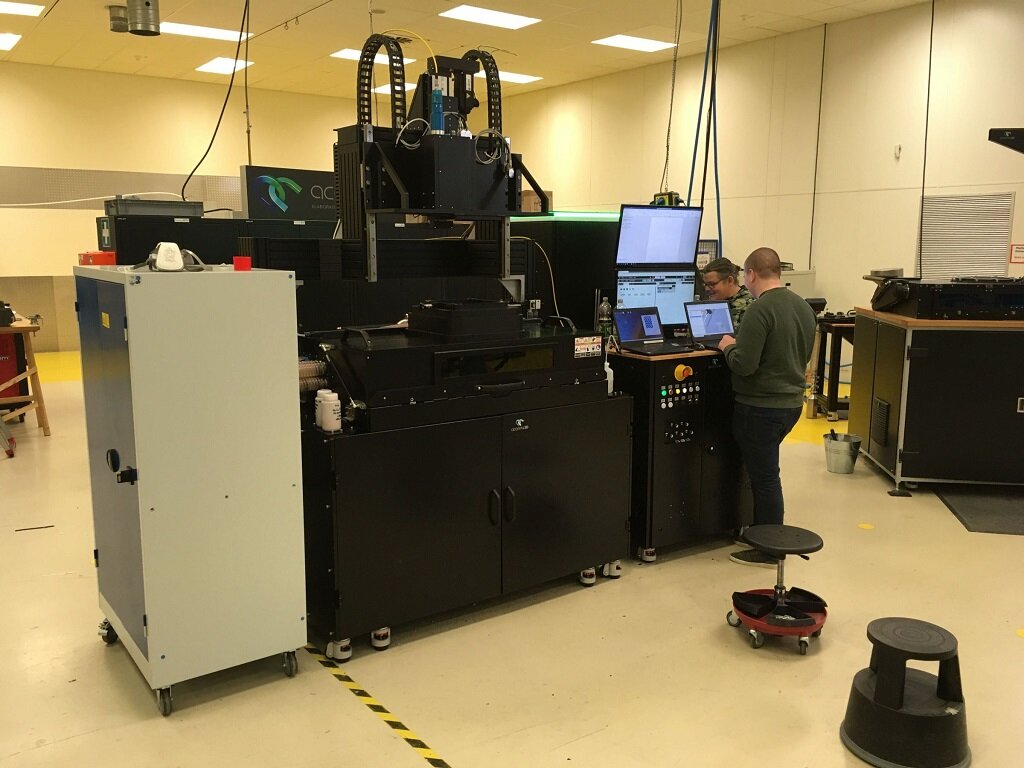

![Aconity Midi + with Aerosint’s powder deposition technology [Image: Aerosint]](https://fabbaloo.com/wp-content/uploads/2020/05/Image-from-iOS_img_5eb0505b6ef41.jpg)

The partnership between Aerosint and Aconity lies at the heart of the current success.

“Fortunately, we found the ideal partner next door in Germany with Aconity3D which had the same mindset of innovation boldness, and who provided us assistance, a custom made printer for the multi-material printhead, and everything required to make this happen together,” Hick tells us. “I’m now really excited since this printer opens the door to a new era of additive manufacturing developments which I’m really eager to discover!”

The agility of this partnership, as well as the partners’ proximity — Aconity’s base in Aachen, Germany is only about an hour away by train from Aerosint’s Liège, Belgium HQ — have been pivotal in their work together, as the teams have told us.

“We invented and designed the recoater but they built the machine in which our recoater fitted and were very supportive of this project very early on. The machine is an Aconity Midi+ system that we will be selling together. The Aerosint recoater is an option on the price list of this machine,” Edouard Moens de Hase, Managing Director, Aerosint, tells us.

Aconity’s systems are modular by design so each customer can get the specific configuration that will be the best fit for their work. The ability to add the Aerosint recoater to the setup allows for multi-metal capabilities to be configured right in.

“The work is done on the all-new AconityMIDI+ system, which is especially designed for housing the multi-material print head,” the Aconity site states. “The multi-material print head is completely integrated into the system and, thus, forms a standard option, available for all end-customers. Current work focusses on further extending the scope of applicable materials and identifying new applications.”

Last year we were looking at the potential commercialization of multi-metal powder bed 3D printing; this year, it’s the reality of availability.

Via Aerosint