![Analyzing a 3D model to prepare projections for use in volumetric 3D printing [Source: Callum Vidler]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb05061448e8.jpg)

A research thesis reveals some of the complexities when designing a volumetric 3D printing system.

A recent comment from Fabbaloo reader Callum Vidler, who saw our story listing known projects working on the incredible technology of volumetric 3D printing, suggested looking at his research thesis, which just happens to be all about volumetric 3D printing.

Volumetric Printing Thesis

Vidler, who submitted the thesis as part of his work for his Bachelor of Mechanical Engineering in School of Engineering at Deakin University in Australia, has done extensive engineering to devise not only a working volumetric 3D printer, but also the specialized resin used in it, and the software required to prepare 3D print jobs to run on it.

![A martini glass produced with volumetric 3D printing in only 45 seconds [Source: Callum Vidler]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb050618be56.jpg)

The project appears to be quite successful, as Vidler was able to 3D print several objects, including a martini glass. Vidler writes:

“The hope of this technology is to one day be used in a similar fashion to the Replicator from Star Trek in where Picard was able to materialize a martini glass from thin air. As a tribute to this vision, a martini glass was chosen to illustrate the ability for the printer to replicate this.”

If there ever was a move in 3D printing history that strikes deep towards the that singular moment when we all realized 3D printing is a truly magic technology that could actually become reality, this is that moment. The martini glass was produced or “replicated” in only 45 seconds.

Volumetric 3D Printing

If you’re not familiar with the concept, it is a revolutionary approach to 3D printing in which a light pattern is beamed at a vat of clear resin from all angles. The object simply solidifies rapidly within the vat, as the light patterns are designed to reverse the process of scanning. More information about volumetric 3D printing here.

Volumetric Printing Design

Vidler’s thesis is quite large, comprising well over 100 pages and 110MB in download form. While it contains a substantial amount of mathematics, I still encourage you to have a read through the work, as it explains many aspects of volumetric 3D printing that you may not have realized.

Keep in mind that Vidler actually built a working volumetric 3D printer, and had to not only construct the device, resin and software, but also had to determine, usually mathematically, mechanically and chemically, exactly how it would work.

I cannot reproduce his work here, but I can offer some highlights that I found particularly interesting.

Photopolymerization Kinetics

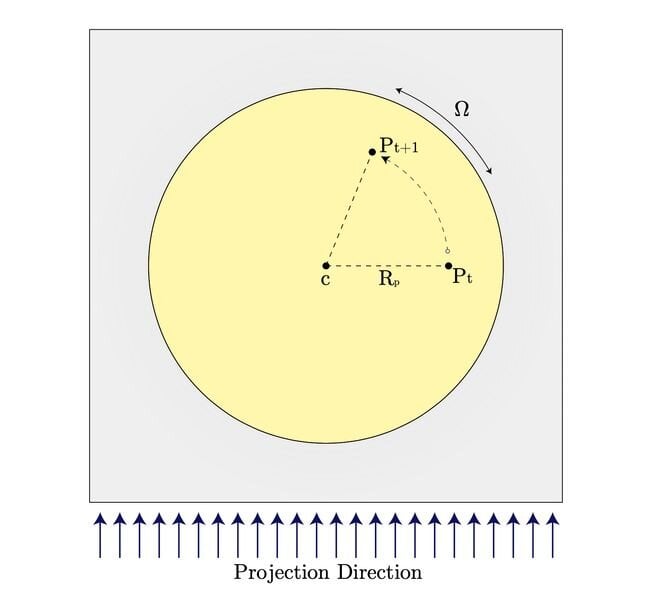

Of particular interest is the rate at which the resin cures to solid form. The patterns that are projected into the resin are complex and varying as, in Vidler’s implementation, the resin vat is actively rotating during printing operations.

There’s considerable mathematics required to determine the cure rates at different voxel locations, and thus the software that generates the projection views must take that into account.

Projection Algorithm

![Refining projection views for volumetric 3D printing using complex mathematics [Source: Callum Vidler]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb05061cd820.jpg)

The preparation of the projection views is incredible complex, as it essentially is determining the reverse of the CT scan process. Instead of receiving a projection of an object from many angles, the software must determine what the projections should be, based on knowledge of the object’s geometry.

The process to develop these views makes heavy use of several techniques, including Fourier transformations and other techniques to reduce “noise”. The results of these processes can create quite a detailed projection, as seen above.

Energy Density

![Volumetric 3D printing projection issues [Source: Callum Vidler]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb050621b5d8.jpg)

Vidler’s approach to the problem essentially involves dividing the volume of the resin vat into a large set of 3D voxels. Then the game is to ensure the energy density applied to each voxel is appropriate for the particular 3D model being produced.

More energy may push the voxel past the point where it will solidify. Less, and it remains liquid. This is an entirely different way of looking at a 3D print job, as most systems use a layer-by-layer concept.

The energy density is not an immediate effect, as the rotating vat will repeatedly expose individual voxels to energy from the projection. This makes things even more complex. As a voxel moves away from the projector, the amount of energy reaching it decreases as the photons must pass through more resin to get there.

Volumetric 3D Printer Design

![Conceptual diagram of a volumetric 3D printer [Source: Callum Vidler]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb050623984d.jpg)

Vidler designed a rather simple mechanical system to implement his volumetric concept. Here you can see a diagram of the device. There’s nothing too magical about it, as it is simply a rotating vat, a DLP projector and a fresnel lens. The lens is used to try and straighten out the projection, which otherwise would diverge as it travels.

In spite of the lens, the light projection still diverges somewhat, and this again adds more complexity to the software generating the projections, as this must be taken into account.

Volumetric 3D Printing Resin

This is one area where I have had many questions, and Vidler’s paper answered most of them.

One question was about the requirement for transparency in the resin. If it’s opaque, how could this work at all? It turns out that it indeed must be at least mostly transparent. However, Vidler proposes formulas to determine the degree by which light signals degrade as they pass through a resin, which again must be dealt with by the projection software.

A surprise to me was that there is a requirement for highly viscous resin, unlike today’s resin 3D printers, which tend to require less viscous resin to allow for quicker layer changes.

The viscous resin allows for 3D printing of objects without any support structures; the solidified elements are suspended in 3D space by neighboring resin. However, Vidler does say that there is a slight density change upon solidification, but the rapid printing operation doesn’t allow enough time for this to matter.

Resin Composition

The viscous resin allows the integration of many more additives than common 3D printer resins could contain, suggesting some interesting materials could be in the works for this technology.

One additive used by Vidler was oxygen, an element normally avoided by resin 3D printers as it inhibits solidification. But in a volumetric system, you actually want to slow down the solidification as the light patterns must pass through resin freely for some distance.

Volumetric Process

![Chart of steps involved in volumetric 3D printing [Source: Callum Vidler]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0506257387.jpg)

This chart shows the steps used by Vidler to succeed in volumetric 3D printing. Note there are multiple very complex steps involved, suggesting this is not something anyone could attempt. There are considerable skills required in chemistry, mathematics and engineering required.

Volumetric 3D Printing Speed

![Volumetric 3D print speed compared to common 3D printers [Source: Callum Vidler]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb050629bcbd.jpg)

As a test, Vidler tested 3D printing identical objects on the volumetric device, an extrusion 3D printer (UP MINI) and a resin 3D printer (Elegoo Mars) to see how they compared. In all tests, the volumetric approach was vastly faster, although results varied by 3D model volume.

This speed comparison result is incredible. It’s also important to note that the volumetric prints are entirely isotropic and thus have no layer boundary strength issues.

There’s a great deal more to be found in Vidler’s thesis, and I strongly encourage you to have a long read through it if you have an interest in volumetric 3D printing.

And if you don’t, you should.

Thanks for the mention, I really appreciate it!

You’re quite welcome – thanks for the great work on volumetric 3D printing!