![Microscopic view of a 3D printed vascular structure [Source: University of Nottingham]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb05063e96e9.jpg)

A research project seems to have achieved the ability to 3D print tiny vascular structures using a bioprinting approach.

Researchers at the University of Nottingham have developed a novel approach to the problem of 3D printing vascular structures in live tissue. These are tubular structures that are found inside every living being, as they are the channels through which fluids flow.

Professor Alvaro Mata says:

“This work offers opportunities in biofabrication by enabling simultaneous top-down 3D bioprinting and bottom-up self-assembly of synthetic and biological components in an orderly manner from the nanoscale. Here, we are biofabricating micro-scale capillary-like fluidic structures that are compatible with cells, exhibit physiologically relevant properties, and have the capacity to withstand flow. This could enable the recreation of vasculature in the lab and have implications in the development of safer and more efficient drugs, meaning treatments could potentially reach patients much more quickly.”

The key point to me is the phrase “withstand flow”, and this is why I believe this is a very important development. It means blood can flow.

How Does 3D Printing Vascular Tissues Work?

The researchers found an ingenious approach to 3D printing vascular structures.

They noted that the proteins intended as material for the vascular structures have a strong attraction to graphene oxide. Their 3D printing approach is to 3D print the vascular structure in graphene oxide, and then the proteins form naturally around them.

Traditional Bioprinting

Up to now bioprinting has been severely limited in a way that is not encountered by other uses of 3D printing technology: the object being produced is alive and must stay alive.

Early bioprinting systems were similar to industrial 3D printers in that they tended to deposit only one or two materials at a time. Typically this would be a dissolvable med-safe material used to build support structures, called “scaffolds” in the bioprinting world, and target cells.

The scaffolds would be deposited and living cells (which could be a mix of different types) would be sprinkled on the scaffolds. The cells would naturally divide and grow, but their collective structure would be guided by the shape of the scaffold.

In this way researchers were able to “3D print” various tissue samples. Perhaps the most famous example was an ear implanted on to the back of a mouse.

But there was a significant limitation: the living cells needed nutrients and those are typically provided by blood flow. However, the “mono bioprinters” were only 3D printing the cell structure and nothing else.

Thus bioprints were usually limited to thin structures through which nutrients would soak through simply due to the thinness of the tissue. This meant that bioprints could not take very complex forms, and much of the bioprinting activity focused around skin and other thin tissue structures.

Vascular 3D Printing

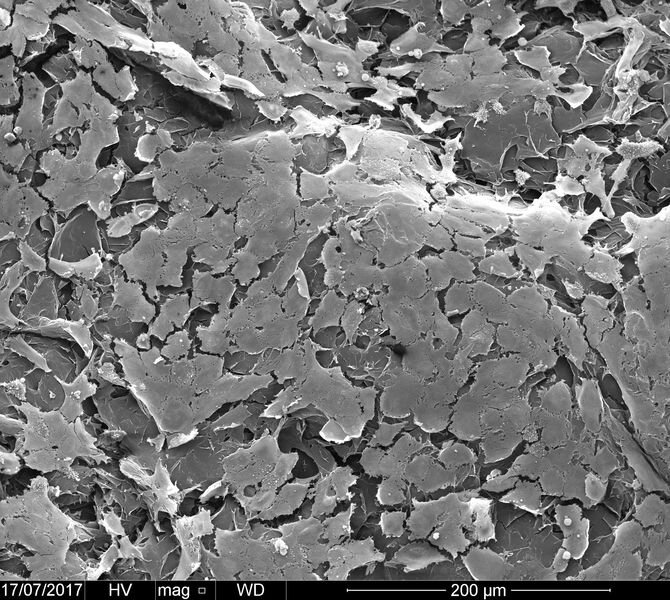

![Detail view of the surface of a 3D printed vascular structure [Source: University of Nottingham]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb050641bf62.jpg)

With the new developments, it seems it may be possible to 3D print far more complex biostructures, as the vascular elements could then supply nutrients to the freshly produced tissue. Think “thick” tissue instead of thin.

This opens the possibility for a myriad of new applications for bioprinted tissue that only those in the medical research community could imagine.