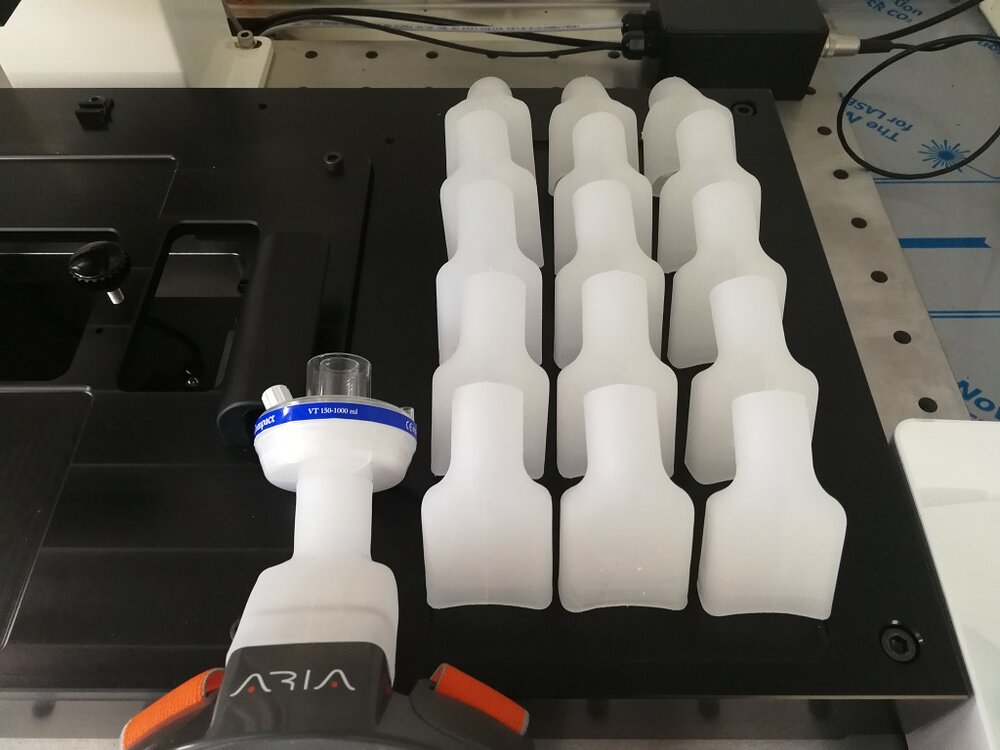

MiMo mask adaptors made using KRAIBURG TM7 MED grade [Image: AddiFab]![MiMo mask adaptors made using KRAIBURG TM7 MED grade [Image: AddiFab]](https://fabbaloo.com/wp-content/uploads/2020/05/IMG_20200407_153807_1_img_5eb0652844e27.jpg)

Scaling up production to help in the fight against pandemic poses certain challenges — that are increasingly possible to overcome.

Most uses of 3D printing in addressing COVID-19 are quick-response, stop-gap supply chain needs for personal protective equipment (PPE) and other need-it-now goods. It is generally acknowledged that these first response measures are just that: a first response, typically the vanguard of full-scale efforts realized by more traditional mass production manufacturing like injection molding.

A new joint effort, though, is seeing the benefit of 3D printing combined with injection molding to have reached a scale solution in six days.

AddiFab

![[Image: AddiFab]](https://fabbaloo.com/wp-content/uploads/2020/05/image001_img_5eb065289b0a4.jpg)

[Image: AddiFab]

Danish and US company AddiFab has a unique offering in the additive manufacturing space: quickly 3D printed sacrificial molds that enable fast-response injection molding. Most of the benefits we discuss with their technology relates to unlocking the geometries of 3D printing at the scale of injection molding, but today we’re looking more at the speed of 3D printing together with that scale.

AddiFab’s Freeform Injection Molding (FIM) technology has led to great interest in its use for prototyping injection molds and low-volume production. Now that interest has been applied to immediate needs in the fight against viral spread.

Much of the required PPE has a relatively straightforward use: prevent droplet (and potential virus) exposure by providing a physical barrier between medical provider and patient. Face shields have become vital in these times, and also offer a fantastic and relatively easy way for those with 3D printers to provide help.

MiMo

![Dr. Michael Mølmer wearing the Ocean Reef Full-Face Snorkeling Aria mask complete with MiMo adapter [Image: AddiFab]](https://fabbaloo.com/wp-content/uploads/2020/05/image002_img_5eb06528cb881.jpg)

Dr. Michael Mølmer wearing the Ocean Reef Full-Face Snorkeling Aria mask complete with MiMo adapter [Image: AddiFab]

Dr. Michael Mølmer, a Danish emergency medical specialist, in collaboration with longtime fellow medical Biodesigner and innovator Mikkel Praest, recently saw inspiration in new ways to expand the availability of PPE.

After seeing Italian colleagues combine an off-the-shelf snorkeling mask with a ventilator, he thought, “If the mask is air-tight enough to protect and ventilate the patient, it ought to be tight enough to also serve as personal protection.”

“My thought was: If we can mount a bacterial removal filter on this kind of mask, we would have a very efficient piece of protective equipment,” says Mølmer.

Upon finding filters and obtaining a high-performance mask — the Ocean Reef Full-Face Snorkeling Aria mask — Mølmer faced the first challenge to his idea: combining them effectively. And thus was born a join effort, as Mølmer, Ocean Reef Group, and AddiFab brought together each of their areas of expertise to quickly ideate and produce a design for clinical evaluation.

Named for Michael Mølmer, the “MiMo” face mask adapter came into being within a week through these joint efforts. Along with AddiFab and Mølmer the collaboration also included medical-grade material provided by KRAIBURG TPE, filter guidance from Pall – Medical, and Mitsubishi Chemical Advanced Materials, which is coming into play as the solution scales up. Ocean Reef Group welcomed the opportunity to see their range of snorkeling masks coming into play in this fast and iterative process.

“With showroom capacity alone, we can produce 100-150 units a day, and the design scales seamlessly into conventional injection molding for larger-scale manufacturing,” AddiFab explains.

Taking a step back, the AddiFab team lays out in quick bullet points what was achieved through this collaborative effort:

-

Use Case: Deliver a connector solution that combines a high-end snorkeling mask and a bacterial removal filter

-

Speed without losing quality: Making use of existing parts made from the best partners already in the market, we created “the missing link” in days

-

Materials grade and properties: The medical grade adapter materials we have used and the properties of these are known and approved by regulatory entities

-

Manufacturing process: We have used our Freeform Injection Molding platforms to both develop and manufacture the adapter. Our manufacturing process scales directly from 1 to many, when needed

Mask Adapter Distribution

![A single MiMo adapter [Image: AddiFab]](https://fabbaloo.com/wp-content/uploads/2020/05/IMG_20200408_161746_img_5eb0652915f35.jpg)

A single MiMo adapter [Image: AddiFab]

The quickly-created design will soon be making its way around the world.

The first samples made their way to the UK for evaluation, and were also tested among Denmark’s front-line healthcare workers. AddiFab’s US CEO, Carsten Jarfelt, has been engaging with hospitals local to him, and further interest is arising as well.

Jarfelt notes that a leading Canadian hospital ordered 2,500 of the MiMo Adapters immediately; Mølmer says that the first 500 units are shipping early next week to Canada.

The teams are keeping their eye on hard-hit countries for further capacity expansion for the adapter, including Italy, Spain, France, the US, and the UK. Mass production is being prepared, should the need arise, working with Mitsubishi Chemical (with whom AddiFab has a longstanding relationship).

The MiMo adapter specifically fits Ocean Reef’s masks. The Italian company is also working on efforts to use its masks to help protect healthcare workers, and is ramping up its production accordingly. Many of their masks are also already out in the world; AddiFab notes, for example, that more than one million of the masks are already owned in the US alone.

“If even a fraction of these masks found their way into US hospitals, we could turn them into protective equipment by just adding the adapters,” says Mølmer.

Via AddiFab