![The first material to debut from the Nexa3D x Henkel materials partnership: 3843-xABS Black Material [Image: Nexa3D]](https://www.fabbaloo.com/wp-content/uploads/2020/05/xABSBlackresinmadebyNexa3D2_img_5eaf97c0dbfb2.jpg)

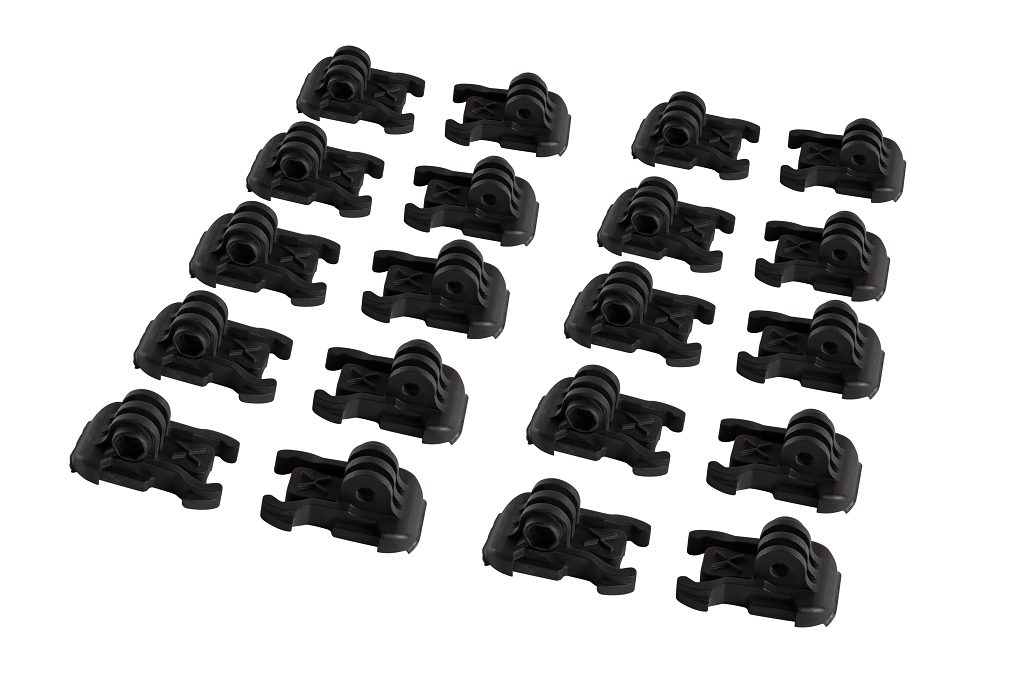

The first material to debut from the Nexa3D x Henkel materials partnership: 3843-xABS Black Material [Image: Nexa3D]

Nexa3D has announced a materials partnership with Henkel.

Functional 3D printing relies on three primary technological aspects for success: hardware, materials, and software.

Open Materials

With more 3D printer manufacturers recognizing the importance of materials partnerships and relying less on proprietary materials that lock users into a relatively narrow selection, such open platforms are on the rise — and when done right, that’s a very good thing indeed.

“Open materials” doesn’t mean “dump any material in and see what the 3D printer spits out,” but rather removes the necessary limitation of locked-in proprietary materials. Many open materials platforms operate through partnerships, as tuning materials to specific systems still requires a good deal of finesse and testing. Setting print parameters to work with a given material ensures that that material performs to the best of its capability on that system.

This is increasingly a critical concern as more and more 3D printers are used to produce functional parts (and of course, especially in the current climate of truly necessary 3D printing production, having that ensured functionality is more critical than ever).

Through a partnership, a 3D printer producer and materials supplier work together to determine the right material formulations for that system. 3D printer producers are working with more and more materials companies to offer a greater breadth of functionalities and capabilities on their systems, just as those materials companies are working with more hardware suppliers to expand the reach of their materials. It’s all about creating the right network to benefit both partners and appropriately leverage their capabilities.

Nexa3D x Henkel

[Industrial-scale 3D printing of functional parts is key to the partnership / Images: Nexa3D]

The latest announcement on this front comes from ultra-fast SLA 3D printer company Nexa3D and Henkel, which produces 3D printing materials under its Loctite brand.

SLA resins will be developed and co-branded through the partnership, offering performance photopolymer materials that will be distributed via Nexa3D’s ever-growing global reseller channels. Nexa3D is the latest 3D printing company to join Henkel’s open platform of material partners.

The partnership is debuting with its first available resin: 3843-xABS Black Material. The announcement describes it the resin and some application areas:

“Nexa3D 3843-xABS Black is a high performance, high modulus material that boasts excellent flexural and tensile physical properties with a relatively high degree of elongation. xABS Black displays high green strength and excellent heat deflection temperature, enabling it to print accurately and function in a wide variety of applications including mechanical assemblies for robotics and automation machinery, bracket, levers and arms for manufacturing stations, and a variety of drones and last mile transportation vehicles parts and assemblies.”

The xABS material is the first, but the press release hints toward a long future of joint materials development to come. Well, more than hints; it says quite clearly, “Both companies are planning to tailor more of Henkel’s expanding portfolio of 3D printing resins to the NXE400 for the benefit of designers and manufacturers seeking to create truly functional parts, across a wider range of applications.”

“We are pleased to partner with Nexa3D as our Loctite Industrial Product portfolio of PhotoPlastic and PhotoElastic materials are well suited for the high throughput of the NXE400 system. The Nexa 3D team have a proven track record of delivering robust solutions and I am confident our combined partnership will deliver the production tools, materials, and flexibility the industry demands,” said Simon Mawson, Ph.D., Head of Additive Manufacturing at Henkel.

Via Nexa3D