Researchers have developed a highly unusual form of 3D printing that allows printing to take place inside a living body.

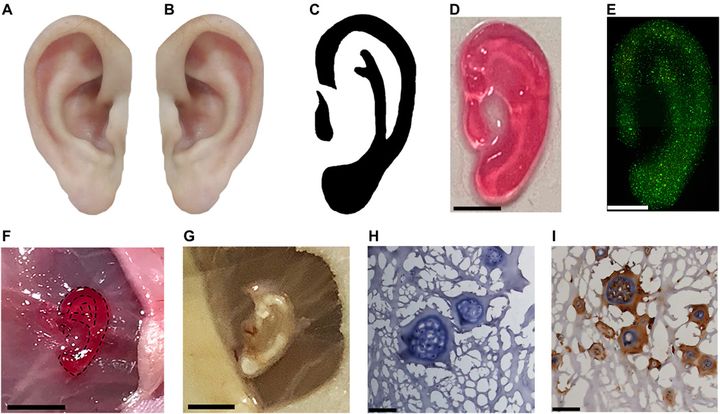

Bioprinting is often done using a photopolymer resin: light selectively cures a photopolymer into a solid structure, as is done with mechanical 3D printed parts. However, in bioprinting there’s a mix of living cells that cling to the structure and grow. Eventually they form into the desired geometry, as governed by the shape of the 3D printed polymer. Finally the polymer dissolves, leaving just the living cell tissue.

The in-situ, noninvasive approach is quite different from typical forms of bioprinting, in which structures of living cells are produced outside the body (in a lab), and then physically implanted in the patient.

These days the healthcare direction is headed towards maximizing noninvasive techniques; that is, not cutting into the body in any major way. This reduces stress on the patient — and hospital — and gets patients healthy faster.

But could bioprinting be done in a noninvasive manner?

It’s been attempted, but researchers found a major issue in that the DLP light used to cure the photopolymers does not easily pass through tissue. This effectively reduced the “Z-axis” of bioprinting, as the light could not penetrate significantly to allow for polymerization.

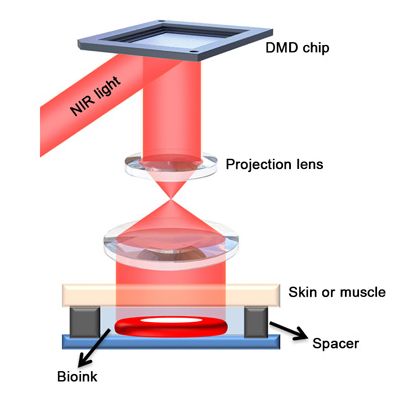

The new research has found a way around this by using a different form of light. Instead of typical light frequencies, the researchers found they could use a form of near infrared light (NIR) at 980nm that could be used for photopolymerization with the right kind of biocompatible resin. In fact, the resin contains specialized photoinitators that transform the 980nm light into 365nm light that enables the polymerization to occur.

How does this process work? It seems there is one “invasive” step, and that is to, prior to bioprinting, inject the patient with the specialized resin in the region requiring the print. This resin is then exposed to the DLP light and photopolymerization occurs.

The researchers explain:

“In this system, by inputting a computer-aided design (CAD) model, the digital NIR is dynamically generated by the connected digital micromirror device (DMD) chip and timely projected to noninvasively induce the spatial polymerization of the local injected bioink layer by layer. Without surgery implantation, customized living tissue constructs were successfully generated in the body. This work would open a new avenue for 3D printing research and advance the noninvasive medicine field.”

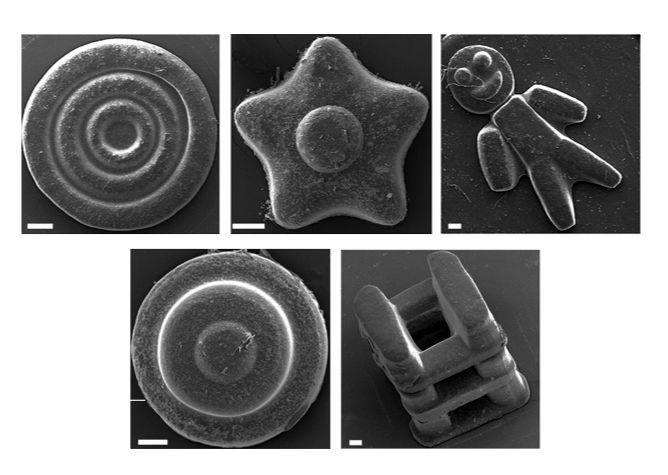

They were able to bioprint layers of 0.2mm thickness in “about 15 seconds”. Apparently they bioprinted various complex 3D structures, such as a truss, cake or “flower-like shapes”.

You (as I) might be wondering how they perform the switch from layer to layer. They explain how this was done in their experiment:

“ A 200-μm-thick layer was printed by the exposure of patterned NIR light excited from DMD for 15 s. For fabrication of a multilayer structure, after the first layer was printed completely, the platform was moved down 200 μm. The same volume of the bioink was added and exposed by NIR light with the second-layer pattern. Repeating this procedure, multilayer construct can be fabricated.”

So it seems that this process operates similar to a typical resin 3D printer, with a Z-axis moving the platform toward or away from the light source. But how could this work in an actual living body?

It seems their experiment involves repeated injections of photopolymer resin. Here’s how it works:

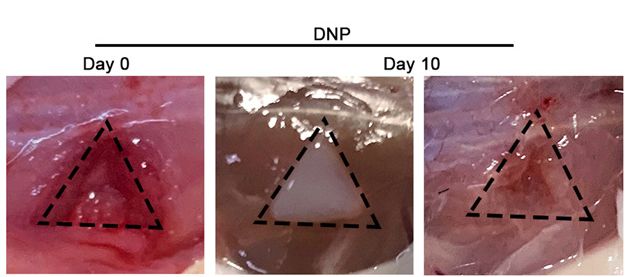

“For the fabrication of a two-layer construct in vivo, first, 50 μl of the precursor solution was injected into the cavity and irradiated by patterned NIR light to print the first layer of the construct. Then, another 50 μl of precursor solution was injected into the irradiated site, and the second layer was printed.”

This suggests that a production version of this approach would involve a small injection of material for each and every layer. That’s unusual, but they have proven the approach works as the experiment was performed on live eight-week-old mice.

It appears the researchers have developed a system that could indeed be used to subcutaneously bioprint structures for various purposes. Now it’s up to other researchers to determine what these structures might be and how they could benefit us.

Via Science Advances