I’m reading an interesting release from Nanofabrica, and had a thought about 3D printer specifications.

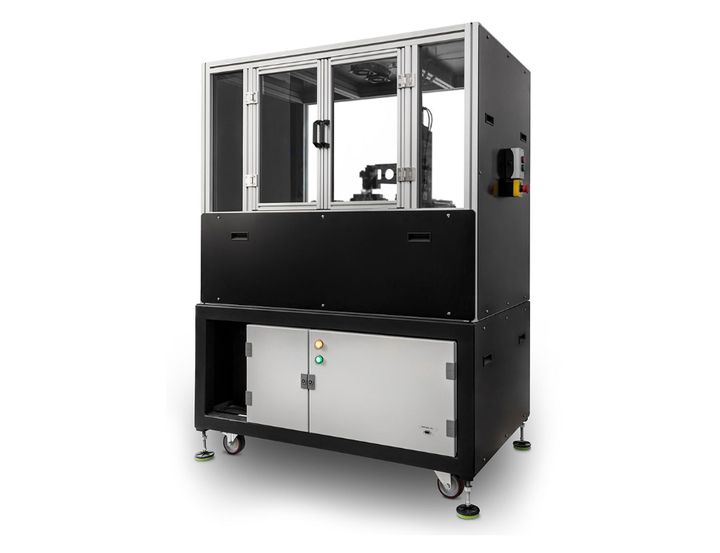

Nanofabrica Tera 250 Name

Nanofabrica is an Israeli company that develops a rather high-resolution 3D printer capable of producing high volumes of very small parts. Their current machine, the Tera 250, has a relatively tiny build volume of only 50 x 50 x 100 mm. However, the machine is capable of 3D printing structures as small as 0.001mm! Thus they have a tremendous capability to produce very small parts.

In fact, they explained the name of the machine, the Tera 250, is based on this resolution. Nanofabrica CEO Jon Donner explained:

“We came up with the Tera 250 as this conveys the most unique aspect of our technology, namely the fact that we manufacture the only commercially available AM platform that can produce micro products with micron resolutions. We have 250 tera voxels in the build volume of the printer, hence the Tera 250!”

Voxel Volume Specification?

I had never seen this method of portraying a build volume previously: by the number of voxels present. By the way, if you’re not familiar with a “voxel”, it is simply the minimum-sized three dimensional space that a given 3D printer can produce. If you have more voxels in a fixed volume, then you have higher resolution. Large voxels mean a coarse 3D print, and small voxels the opposite. Nanofabrica is focused on the latter.

But this concept gave me pause to consider whether this could be another specification for 3D printers in the future. Would this be of value to know? Is it even knowable for all 3D printers?

For Nanofabrica’s 250 tera voxels (let’s call them “TVs” for now), that would imply a cube with 63,000 steps on each axis. Of course, the Tera 250’s build volume is not exactly a cube, you get the idea here.

Could this specification be known for other 3D printers? For some it is definitely possible.

Voxel Volume For DLP And LCD 3D Printers

In the case of a DLP or LCD 3D printer, the calculation is straightforward: determine the number of pixels illuminated on each layer, and then multiply by the maximum number of layers possible in a build job. The maximum layer number would be equal to the Z-axis divided by the minimum layer size.

Let’s figure this out for a typical LCD 3D printer, the ANET N4 (for which we recently did a comprehensive hands-on review).

The N4 uses a standard LCD as its light engine, and it has 2560 x 1440 pixel resolution. For each layer produced in the 3D printer, it will produce 2560 x 1440 = 3,686,400 voxels. The N4 also has a build volume of 120 x 65 x 138 mm, but it’s the Z-axis we’re interested in here, 138mm.

The N4 can produce layers as small as 0.040mm, meaning the tallest print job would include 138.00mm / 0.040mm = 3,450 layers.

Combining this with the pixel count we have 3,450 layers X 3,686,400 = 12,718,080,000 possible voxels, or 12 GVs. That’s vastly less than Nanofabrica’s 250 TVs (or 250,000 GVs). From this comparison it is totally obvious that the Tera 250 has an enormously finer resolution.

As long as you know the pixel count on the light engine, it’s easy to calculate the voxel volume for a 3D printer. But is that available on other types of 3D printers?

Voxel Volume For FDM And Other 3D Printers

While pixel counts are easy to find on some types of 3D printers, they are not available for other types of 3D printing. Methods such as material extrusion, PBF, SLA and others don’t use fixed-pixel methods of solidifying material. Instead they use “continuous” methods such as an extrusion thread or sweeping laser to solidify material.

Continuous methods do not really provide any way to measure X-Y resolution, so this might not work for those types of 3D printers.

One might suggest that you could examine the resolution of the motion system’s X-Y axes stepper motors to see the minimum distance that could be generated. However, that won’t work because the motion system is moving a “blunt instrument”, being the laser dot or hot end nozzle.

Imagine if you computed this using the stepper motor specs and then changed the nozzle from 0.4mm to 0.8mm. The voxel resolution would certainly change. Similarly, laser power could vary the area of melting in a PBF 3D printing system.

The Voxel Specification

Is the “voxel specification” something that could be useful?

In the case of LCD, DLP and other projection-based 3D printing systems, most definitely. By comparing the ANET N4 and Tera 250 specs it is patently obvious there is a fundamental difference in the two devices that is not at all apparent in their build volumes.

I think that manufacturers might want to start listing this new specification as it would greatly aid in understanding their equipment.

On the other hand, with an inability to easily compute the voxel specification for most other 3D printing processes, it can’t be useful, at least for those devices.

In any case, the Nanofabrica Tera 250 should really be called the Tera 250000.

Via Nanofabrica