One of the first question I always hear from 3D printing newbies is “How Big Can I Print?” But that isn’t really a good question.

To be clear, the build volume on a given 3D printer can be a useful specification to examine, but it isn’t quite what you might think it to be. While you might think that specification determines the maximum possible print size, that’s not quite true.

3D Printer Build Volumes

The build volume is essentially the dimensions of the space into which 3D prints can be produced by a specific machine model. Typically they are stated in Cartesian form, with values for each of the X, Y and Z axes. That’s because many 3D printers use a Cartesian-style motion system in which there are literally three axes of motion and the numbers correspond to the maximum reach of each axis.

Build volumes can be specified differently, however. For delta-style machines the build volume is usually specified as a cylindrical, not cubic, space. There’s a diameter and a height, and this again correlates with the reach of the delta motion system.

Usually.

3D Printer Build Volume Quirks

Sometimes these build volume specifications are not quite right. For example, in multiple-extruder devices, the build volume can change.

How so? It’s because many dual extruder setups involve mounting a pair of hot ends on the X axis. As the system operates, these two hot ends move back and forth synchronously on the X-axis because they are literally bolted together.

But if you think about it, the left extruder cannot “reach” all the way to the right side because the right extruder is in the way! Similarly, the right extruder can’t get to the left side because the left extruder is in the way.

Because of this the build volume shrinks on the X-axis slightly. Most often you’ll see two different specifications, with one larger than the other. The smaller build volume occurs when the second hot end is involved in the job.

There’s also the issue of the extreme ends of the build volume being practically inaccessible. Sometimes the actual reach will be short by a few millimeters, but few 3D print at that position, so no one notices. Myself, I always try to leave at least a few millimeters between the print and the “edge” because I’m never sure if the edge is actually there.

Delta 3D printers also have similar weirdness. Sometimes you will see the specification as X diameter and Y height, suggesting a cylinder of that size. However, you cannot usually 3D print within that space because of quirks in the motion system.

With a delta motion system there is a highest point that the hot end can reach when all three arms hold the hot end at the highest point in the center. But when that happens, there is no slack left in the arms to move to the sides. You are really able to reach that maximum height only when in the center of the cylinder.

Thus you cannot usually 3D print near the top edges of the build volume’s virtual cylinder. Regardless of that, the system makers specify the “maximum height” as a number that is legally true, but not functionally true.

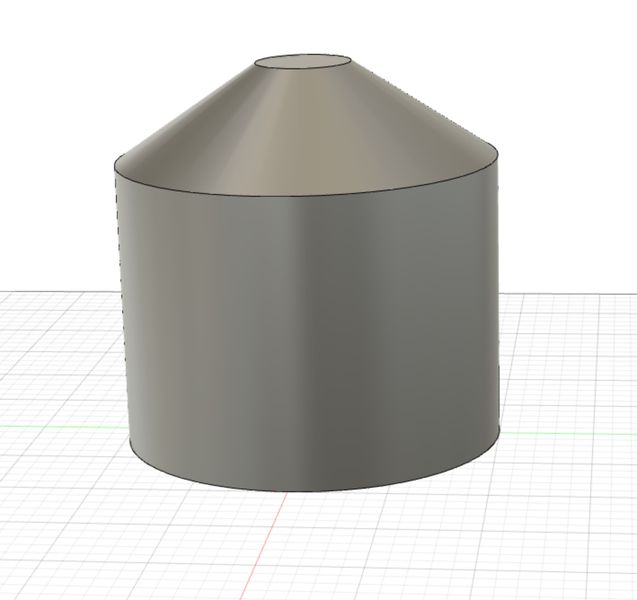

The actual build volume for a delta machine is shaped more like a cylinder with a cone on top. Fortunately, most 3D print jobs involve short objects or ones that don’t venture into that territory, so no one notices.

Making 3D Print Build Volume Bigger

If you were given a build volume of say, 200 x 200 x 200 mm, and asked how big an object you could 3D print, the answer is also a bit tricky.

You could say the maximum size could be 200mm. Or perhaps 195mm by allowing a bit of margin. But that’s not the right answer. You could do this:

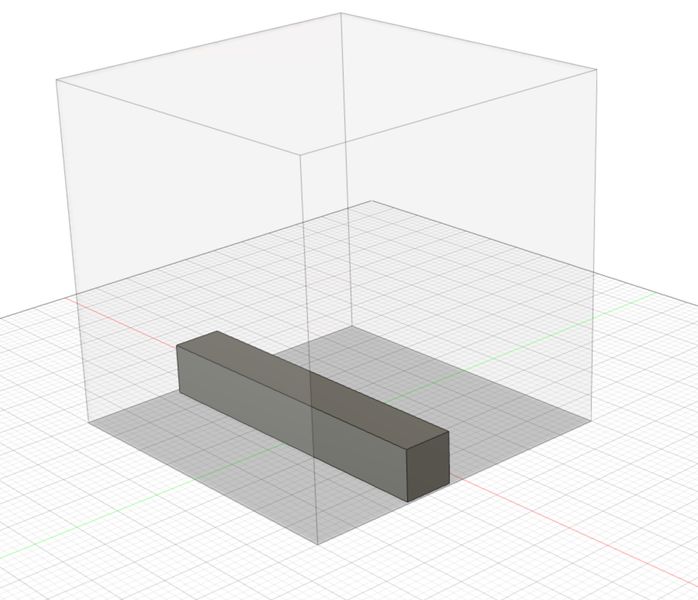

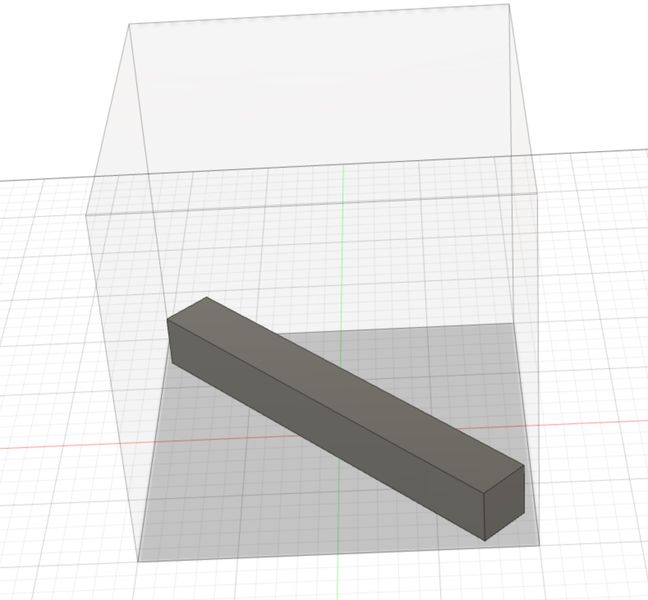

You could orient your object along the diagonal, and this allowed me to make the block 240mm long. This provides a slight extra boost to the maximum length, and you can exceed the stated dimension.

But wait, there’s more! You could do this:

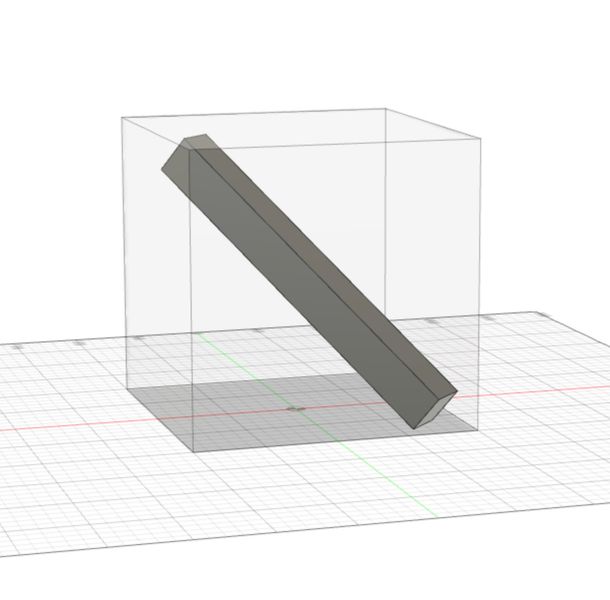

I was able to make the block 260mm long, and it still fits on a “200mm” 3D printer.

This is likely the maximal method for achieving the biggest possible 3D print within a fixed build volume. However, it isn’t recommended as you may have adhesion problems, and waste a ton of support material. That’s to say nothing of the work required to remove all that support material.

But sometimes you do need to exceed even this length, and there’s a very simple way to do that: break your 3D model into smaller parts. Print them and assemble them later. One of the best ways to perform the split is to include holes and pins in the connecting surfaces to ensure alignment. Also, if you are breaking into a larger number of parts you might want to incorporate a numbering system so you can keep track of which part is which.

Finally, the introduction of belt 3D printers changes the build volume game completely. These devices can literally 3D print infinite distances on one axis, so long as you keep supplying material to the machine.

That, and holding up the endless 3D print, as was done in this experiment where a 6m 3D print was achieved on the White Knight device.

Back to the original question, “How Big Can You Print?” The answer, as you now know, is this:

It Depends.