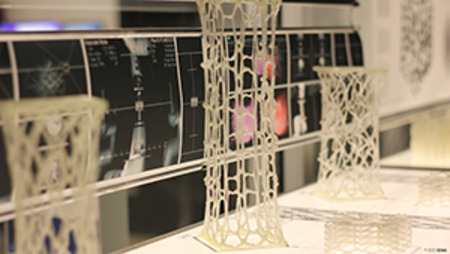

In what could be a preview of the future of architectural design, Los Angeles-based architecture office ID4A has created a method for creating pliable, reconfigurable 3D prints.

According to Rania Hoteit and Malek Idriss, principles at ID4A, their new method for architectural “hyper-prototyping” employs a “rigorous exchange between computational design, physical prototyping and additive manufacturing.” By combining these three tools, the young architects have designed a system that can build pre-formed rigged structures and mold-less scaffolds that are easy to control and manipulate even after they’ve been printed.

As part of their “patent-pending” process, ID4A uses a material blend consisting of polymers and composites to create a substrate that is “pliable and transformative until being fixed by scripting 3D vectorial geometry networks, programming materials and… [applied to] robotic motion.” To achieve this result, ID4A programs their materials with algorithms that allow them to snap to a number of “formal states,” giving every print the ability to take on multiple forms.

Read More at ENGINEERING.com