We managed to get our hands on some new Amphora filament from colorFabb and performed a few tests.

As we described earlier, Amphora is a brand new polymer developed by Eastman specifically for use in personal 3D printers. The material is quite strong and has extremely good safety qualities, so we were quite interested to give it a try.

The Amphora material we obtained from colorFabb, “XT-Copolyester”, is quite nice to print. It’s very strong when printed thickly, yet flexible when printed sufficiently thin. So long as you don’t crush a flexible print, it will rebound to its original shape. We were able to print 0.1mm layers that produced very nice prints like this Madonna.

As advertised, this filament produces no detectable odor while printing, unlike virtually every other filament we’ve tested. Something to keep in mind when sniffing a 3D print: the hot end melts the filament and also vaporizes a very small amount, which condenses into nanoparticles that float through nearby air. That’s what you’re smelling. In the case of XT-Copolyester, you simply don’t smell anything.

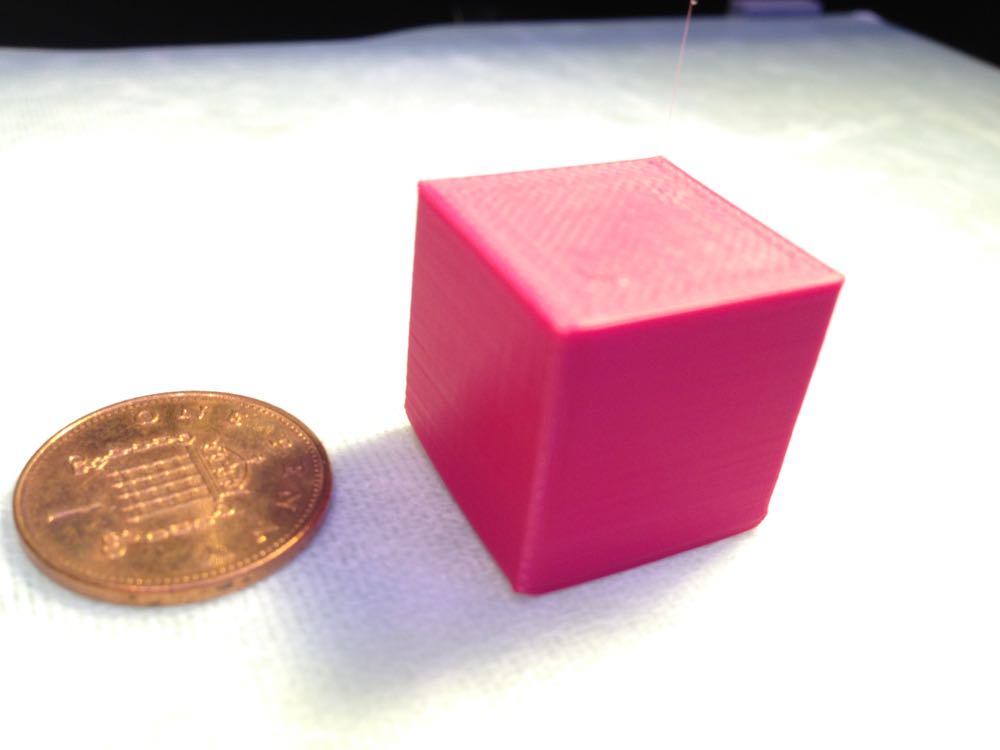

Another feature of this material is its surface appearance: prints are quite shiny, which can be an attractive feature on some models. colorFabb sells XT-Copolyester in a variety of very cool colors, too.

We found temperature settings had to be higher than plain old PLA, with around 250-260C showing us the most success. Less than that resulted in prints that easily split along their layers. However, once the temperature is correct, prints were quite solid.

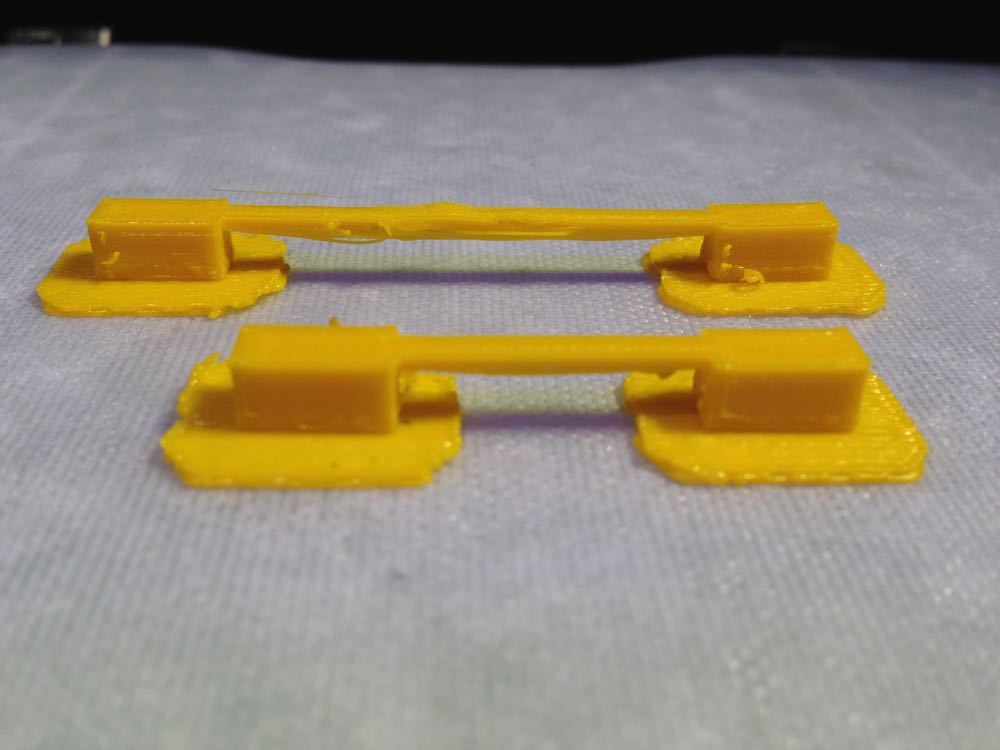

We tested a few bridges and found them challenging to print. We could barely achieve a 40mm bridge as shown here. However, we have previously seen 150mm bridges, so it probably requires some experimentation with settings to dial it in.

One issue we encountered was stickability. We strongly recommend using a heated build plate for this material. On our “cold plate” equipment we were unable to achieve reliable sticking after trying all common sticking solutions: acrylic, blue tape, hair spray and a selection of various glues and glue sticks.

This material does shrink slightly after extrusion, complicating the sticking problem. We had several larger experiments fail as the print warped itself off the print surface. We suspect large prints are simply not possible without a heated plate, although you can manage smaller prints if they finish quickly.

Is Amphora a good material to 3D print? Absolutely – just make sure you have a heated build surface before you order some.