With the growing list of crowdfunding failures recently, it seems to me that these projects should have been taking steps to provide more assurance to their backers.

Typically, projects simply post technical specifications and hope that prospective buyers will be persuaded to part with their money on the basis of those (hopefully) amazing specs. Sometimes that works.

But very often it does not.

Why? Because producing and delivering a machine that works is very different from being able to make a single machine. Successful launches will tell you the biggest challenges are not getting a machine to work. No, they’ll tell you the hugest barriers are related to volume production: shipping, acquisition of required components, reliability of those components, cross-border issues, unexpected delays, cost changes in the supply chain, assembly efficiency and so on.

Making one machine is a very different matter than making a thousand. And when a company bumps into that problem, they usually fail because unless they have actual manufacturing expertise on hand, they likely won’t be able to withstand the learning curve required. That learning will stretch out the time required to the job done, and in the process they may run out of cash. Then the fun starts, eventually landing on an unfortunate announcement of the project’s conclusion.

There’s one interesting service that could certainly help many startups in this area, however, yet few projects use it: Dragon Innovation.

Dragon is a company that will provide a very detailed analysis of your hardware project and can provide a variety of useful services for startups.

They can produce a detailed Bill of Materials that will reliably show the true cost of the machine’s components at volume. Dragon explains this information can help you calculate:

- Lead-time to procure the materials

- Cost of Goods Sold(COGS)

- Manufacturing processes

- Quality of the Design for Assembly

- Supply chain robustness

- Cash flow requirements

They can provide a manufacturing plan, even selecting an appropriate factory to produce the units, as well as supervising it during production. This could also include:

- Factory contract negotiation

- On-site project management & support

- Schedule and budget planning

- Independent inspections and factory oversight

- Certification process coordination and assistance

- Iterative design reviews

- Component sourcing

- Total product lifecycle cost reduction

- Creation and implementation of quality and testing plans

- Schedule negotiation/acceleration

- Sustaining engineering strategies

- Rapid response/“fire fighting”

- Factory relationship management I

- P handover process

- Supply chain management

- Independent quality audits

Many of these skills are often not present in a typical startup team, yet most of them are things that actually MUST BE DONE if you hope to really produce a hardware product that works and is delivered to customers.

Finally, and this is the Kickstarter part, Dragon can provide an official “Dragon Certified” stamp for a product launch. What does this mean? They do these reviews:

DFM Analysis: We perform a Design for Manufacture and Assembly analysis in which we inspect and analyze the product desig to ensure that the product can be manufactured reliably and at low cost.

BOM Review: We examine the Bill of Materials, an itemized list of all the product components, for completeness and cost efficiency.

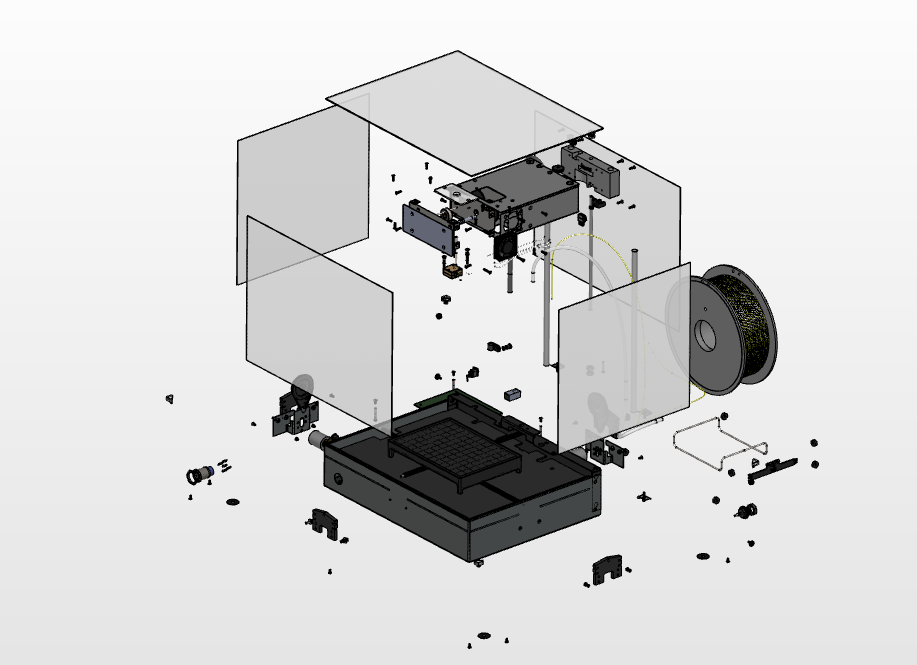

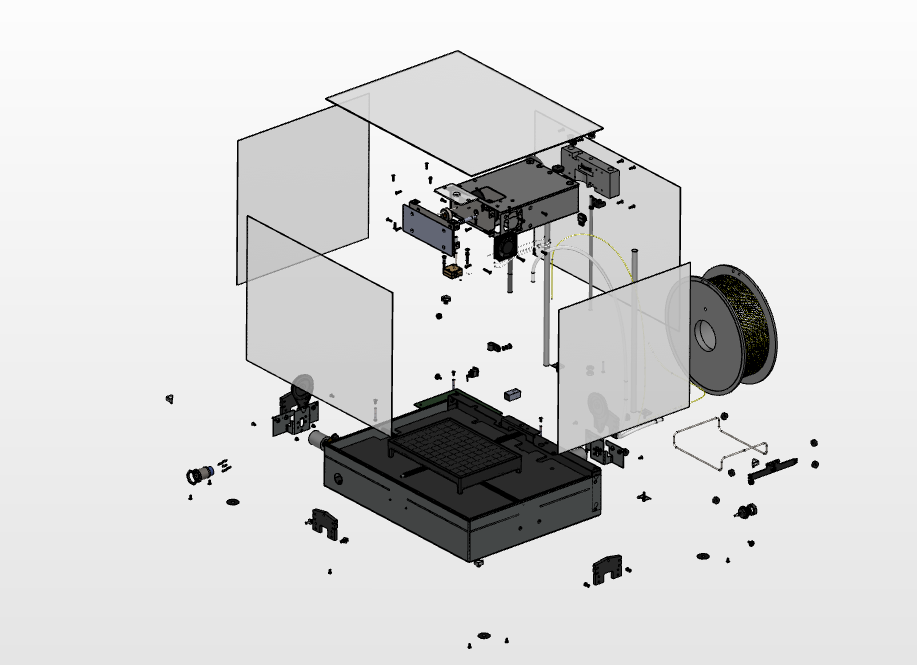

Mechanical Tear Down: We disassemble, inspect, and analyze the structure and assembly for function, cost, quality, and reliability.

Packaging considerations: We determine suitability and cost of chosen packaging design and make recommendations to optimize it.

Estimated domestic and far east manufacturing costs: We develop cost estimates for domestic and Far East factory options.

Pro-forma manufacturing schedule: We produce a preliminary manufacturing schedule based on our review to help provide a realistic estimated ship date.

From these you can determine whether your design is actually manufacturable, how much it will really cost to produce and how long to do so.

One 3D printer company that’s done this is New Matter, who obtained a Dragon certification for their MOD-t device. You can see the official certification here.

Imagine if the Kickstarter project you’re examining had this certification. Would you think differently about the project? I certainly would!

Imagine if EVERY 3D printer startup had such a certification!

That’s unlikely to happen, as Dragon’s services are not free and would be an extra expense for startups. However, in my opinion, that kind of analysis is worth every penny – not only for the startup’s benefit, but also for their backers.

3D printer startups: Just Do It.