![Visualizing a 3D printed voxel being solidified in real time [Source: Advanced Science News]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a3d8980c3.jpg)

A method has been identified to monitor how photopolymers cure during energy exposure.

Researchers from the National Institute of Standards and Technology (NIST) have discovered a practical method of understanding exactly how photopolymers solidify under energy application. This mysterious property has allowed the entire SLA 3D printing world to exist, yet until now it has not been properly understood.

Photopolymers are liquid resins that react when exposed to energy, typically laser light at specific frequencies. The reaction involves binding the molecules together and transforming the liquid into a solid. By selectivity applying the energy to a liquid, arbitrary solid shapes can be created. This approach has been used to develop a larger number of 3D printers and many varied photopolymer materials.

But exactly what happens when the laser hits the resin?

In metal 3D printing this is a significant issue, because that process requires proper crystallization of the liquid metal formed by laser illumination as it cools. Because of this, some metal 3D printer systems include “meltpool monitoring” features that attempt to ensure the overall quality of the print by making certain the meltpool is adequate.

There doesn’t seem to be any equivalent of this in the SLA 3D printing world. But perhaps there could be one now.

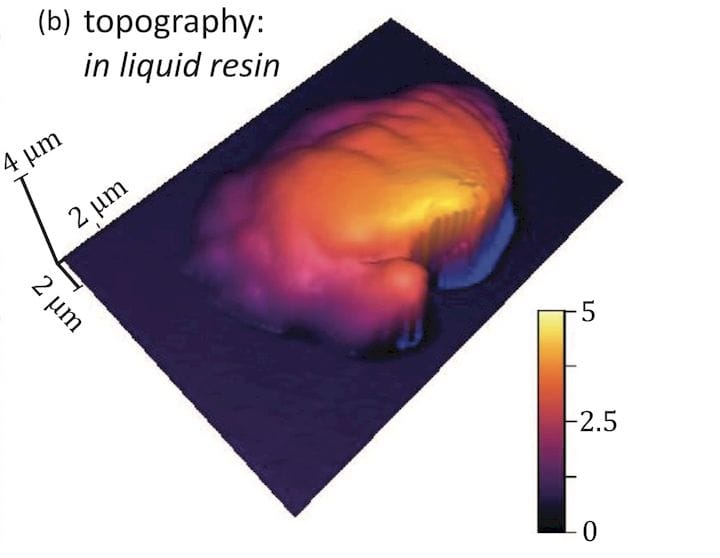

The researchers used an atomic force microscope (AFM) technique they call “sample-coupled-resonance photorheology”, which we will mercifully abbreviate as “SCRPR”. Basically, it is a method of observing deformation flows at a microscopic level.

![Using an atomic force microscope to monitor photopolymer solidification [Source: Advanced Science News]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a3d90c131.jpg)

They coupled an AFM sensor to a laser and used it to observe a photopolymer reaction in real time, recording the results and did so in “relevant reaction kinetic timescales”. In other words, they were able to slow down the recording to actually observe the solidification taking place.

Using this arrangement they were able to experiment with different degrees of laser exposure to see the effects on the resulting solid. They produced charts illustrating, for example, the effect of different laser power levels on the strength of the resulting solid.

I’m very interested in this work, as it might lead to a new world of SLA 3D printing. Up to now those doing the tuning on such devices have essentially been guessing as to the optimum print settings. This is done by testing the entire print at completion.

But the entire print is made up of countless small solidification actions undertaken by the laser at microscopic levels. These could be examined in great detail to determine better ways to optimize part strength and even energy use: Make better buildings by using better bricks.

I am imagining a future SLA 3D printer that’s equipped with an AFM tip that rides along with the laser to constantly monitor the quality of the print to ensure it is within tolerance levels, just as is done in some metal 3D printers. This could dramatically increase the quality and possibly performance of SLA 3D prints.

However, the day such a machine emerges could be a a while, as the researchers appear to have done their experimentation only on a single drop of photopolymer with a static laser setup. Could this work in real time as a laser zips along at high speed? That could be a very difficult engineering problem.

Nevertheless, this opens up some interesting possibilities.

Via Wiley

A research thesis details the incredibly complex world of volumetric 3D printing. We review the highlights.