An interesting partnership has resulted in a new material for 3D printing.

Materials are king in 3D printing these days: if you want to make an object for production or even prototype use, it had better exhibit the correct engineering properties. That is accomplished best by using the right materials to make the object.

However, in today’s world of 3D printing the number of materials available is vastly constrained when compared to the staggering catalog of materials used in conventional making systems.

This gap has resulted in many companies NOT using 3D printing, simply because they can’t make the right part. They can make the SHAPE, but they cannot make the PERFORMANCE.

Thus begins the endless search for new and interesting engineering materials for 3D printing. Now there’s a new one, called “CARBOPRINT”.

It’s the result of a collaboration between 3D printer manufacturer ExOne and the SGL Group. SGL Group is a “leading manufacturer worldwide of products and materials made from carbon.” ExOne is known for their large-scale 3D printed molds and sand-style 3D printing using a binder-jetting process.

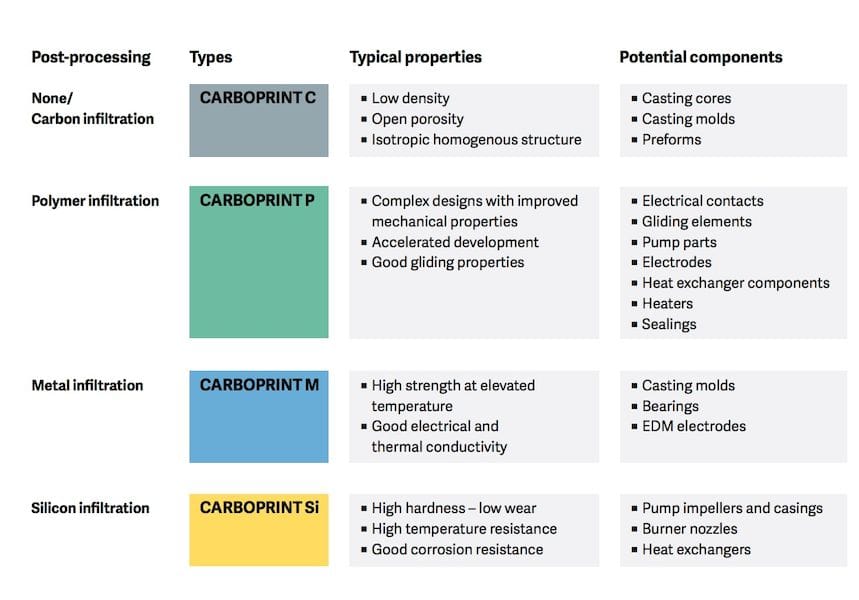

It seems the technical collaboration here is in two phases: first ExOne uses their binder jetting process to 3D print a carbon shape. This object will be quite porous, as is typical with carbon objects. Then SGL Group applies their magic with a series of post-processing steps that, for example, infuse the object with polymer, to create a new material. This is what they call “CARBOPRINT”. It’s actually a family of materials with different properties.

The new materials are said to have some very useful properties:

Thanks to the basic properties of carbon, such as high chemical stability and good electrical and thermal conductivity, first trial components are being developed for testing in applications in the areas of chemical apparatus construction and environmental technology. Specific examples include heat exchangers and components for distillation columns, as well as pump components made of siliconized 3D-printed carbon.

Note the last sentence, where it becomes clear that this material is NECESSARY for particular applications. That’s what the 3D printing industry is seeking these days: application of 3D printing, and that is most often barred by lack of materials.

One door seems to have opened with this announcement.

Via BusinessWire and SLS Group (PDF)