This is interesting: Essentium and BASF are working together on some electrifying 3D print materials.

And when I say “electrifying”, I mean that in the literal sense.

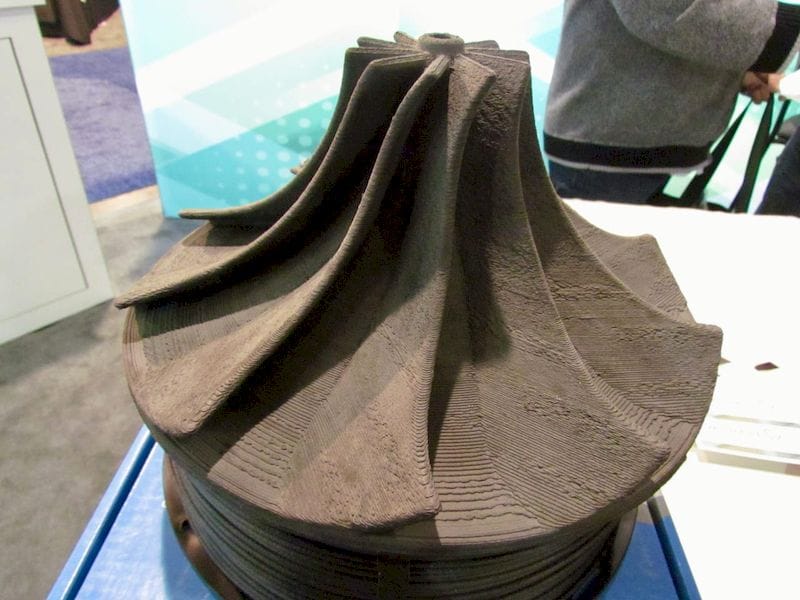

You see, Essentium is a company that produces one of the most unusual 3D printing processes you’ll encounter. Their FlashFuse process might visibly appear to be just another plastic filament extrusion technique, but it’s quite different.

One of the problems with plastic filament extrusion is that the layers are subject to heat differentials, causing warping. Inadequate heat can also lead to poorly laminated layers and weak parts.

Essentium attempts to solve these and other issues by literally electrifying the filament. Their process involves applying an electrical current from the hot end, through the filament and partial print, to the conductive base plate. As the energy flows through the system, the material heats up. This heat provides a means of reducing warpage and ensuring the layers stick much better to each other.

Their system involves two key components: the electrical system and the conductive filament material.

Their process was announced well over a year ago, but since then we haven’t heard too much about them. It may be that development of the conductive materials may be difficult, particularly in an age of 3D printing where clients are increasingly seeking more unusual materials with specific engineering properties. For a 3D printing company to survive these days means they must have a regular flow of such new materials.

Now we see that Essentium has partnered with BASF. BASF, one of the largest chemical companies in the world (if not the largest), has more expertise in the development of materials than practically any other agency. They’ve also shown significant interest in the 3D printing market over the past two years, partnering with several 3D printer material and equipment providers to supply materials.

Their catalog of materials is vast, and large portions of it contain new 3D print-suitable materials that haven’t yet been deployed to the industry. That’s what most of their partners have been seeking: access to a huge library of engineering materials to help satisfy their clients’ demands.

But a deal with Essentium might be a bit different, as the materials must work with the FlashFuse technology: conductive and heat generative. BASF explains:

The offer also includes comprehensive expertise in application development and knowhow in fused filament fabrication (FFF). The cross-regional distribution agreement covers several products. They include Ultrafuse Z, a special, extra strong filament based on BASF materials, further developed by Essentium, and offered in combination with Essentium Materials’ processing technology, FlashFuse.

This could most definitely be a huge short cut for Essentium to develop a much wider variety of engineering materials for 3D printing that work with their electrified approach.

When you don’t have the resources to do it yourself, find a partner. Preferably, a big one.