I’m reading an interesting story of how jewelry designers applied a new 3D printing technology.

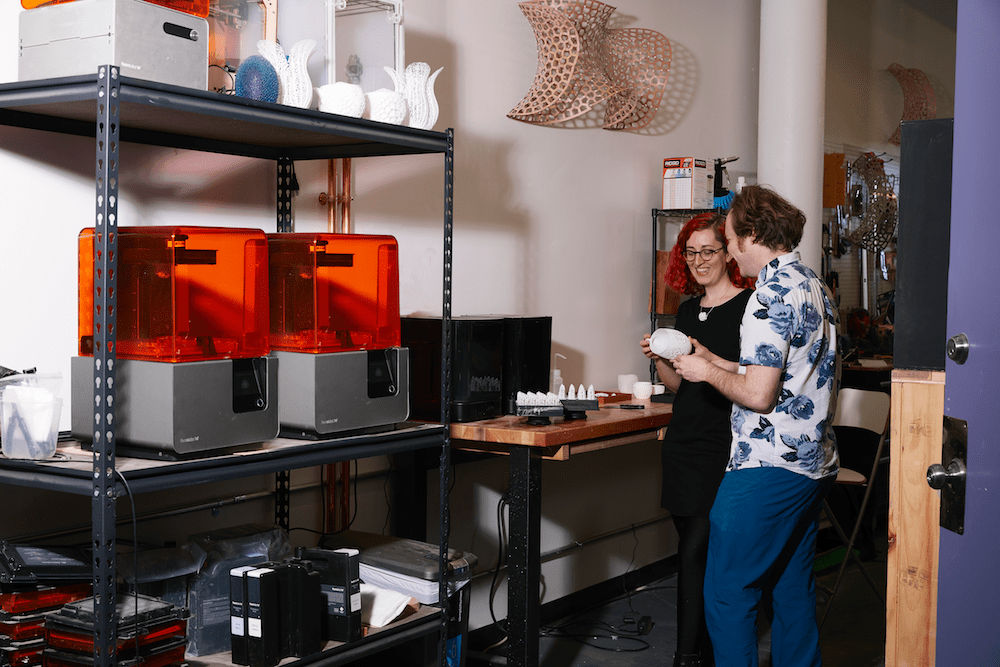

The designers were, of course, from Nervous System. They are a team of designers who have been using 3D printing for a very long time. Recently they’ve announced a new line of fashion jewelry based on new ceramic 3D printing tech from Formlabs, which we wrote about last week.

Here’s what they say:

Porifera is a new jewelry collection by Nervous System inspired by the forms of deep-sea glass sponges and made in a new 3D-printed ceramic material. It is the result of two years of material experiments and research in collaboration with Formlabs. By combining new technologies and traditional crafts, ceramic 3D-printing lets us create intricate forms which cannot be manufactured by other methods. Each piece is finished by hand: sanded, glazed, and fired twice in a kiln up to 2340F, creating vitreous ceramic jewelry with a sumptuous glazed finish.

Wait, they spent TWO YEARS working with Formlabs to develop this approach? That seems like a long time, but on the other hand, it was a new technology from Formlabs. Nervous System also says:

The sinuous, space-filling surfaces of the jewelry were inspired by the forms of glass sponges. Glass sponges build reefs with complex, porous architectures that are home to many species. Nervous System created custom software to computationally generate the designs. The software generates minimal surface networks along cellular scaffolds that adapt to different volumes and densities. The technique results in thin-walled 3D foams that can only be manufactured with 3D printing.

Ah, this explains some of the long development period: they had to devise new ways to generate appropriate geometries that were compatible with – and profitably leverage – the new Formlabs ceramic technology.

And they’ve got it done to the point where they are using the Formlabs ceramic tech to produce their products for market.

The lesson here is that using 3D printing technology – properly – is not a given, and it is not instant.

It takes considerable time to mentally devise a target design that:

- Will be a marketable product with customers and prospects

- Is feasible to produce using the technology

- Can be made reliably in suitable quantities

- Leverages some aspect of the technology that cannot be easily duplicated elsewhere, making the products unique

- Is financially feasible (cost to produce is appropriately less than the sale price)

Nervous System has gone through this process and apparently successfully so.

But can any company do the same? Proper use of 3D printing technology is not something you can just turn on. Well, you can literally turn it on, but you won’t get the most value unless you have spent time to consider the factors listed above.

In the past I’ve heard the story many times where a company dismisses 3D printing because “it’s just more expensive than what we’re doing now”. Well, yes, that can certainly be true – if you are DOING THE SAME THING you have always done.

DON’T DO THE SAME THING. Be different. Be unique. Be leveraged.

Via Nervous System