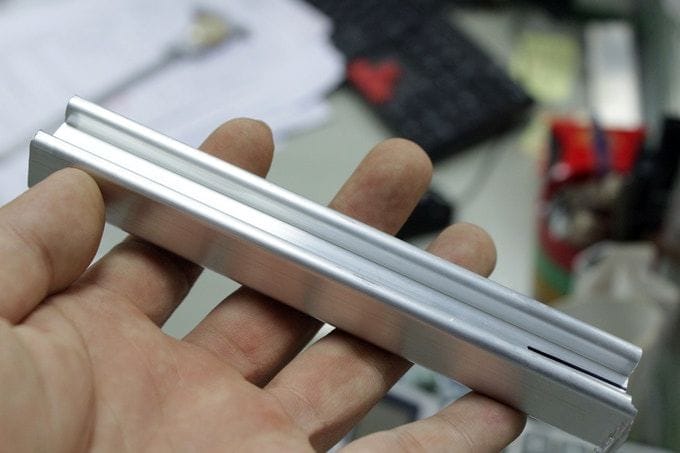

![A low-cost sample metal extrusion made for the IVI 3D printer [Source: IVI 3D]](https://fabbaloo.com/wp-content/uploads/2020/05/ivi-extrusion_result_img_5eb098c94d97c.jpg)

We’ve received additional information about the IVI 3D printer detailed last week.

This is a new machine just launched on Kickstarter, and it’s been very successful in raising funds. As of this publication, their launch campaign has raised an astonishing US$585K, and still rising.

Levels of Kickstarter launches of this magnitude have not been seen for quite a while, as the strategy of crowdfunding has been mostly exhausted. Over the past several years, multiple parties launched crowdfunded devices, but most of them were essentially technically indistinguishable from each other.

Even worse, there have been countless launch failures, scaring away many potential clients. In many of these cases, failures were due to drastic mismanagement of manufacturing at scale processes. Thus we always like to inspect the manufacturing capabilities of the startup company. In fact, we wrote a Kickstarter checklist of things to be concerned with in such situations.

In the case of the IVI, we’re concerned with their manufacturing capability for sure, but we’re also concerned with their rather low price: US$799 for a delta 3D printer that uses both extrusion and SLA processes, as well as providing laser scanning, engraving and CNC milling. Thats about US$150 per process. Oh, and it uses a closed loop process for high quality and reliability as well.

If a device manufacturer drops their price too low, then there’s often a feedback loop that dooms their project: A low price attracts more orders, but more orders means a far more complex and risky manufacturing cycle. If, for example, the wrong components were ordered and have to be re-purchased, will there be sufficient funds remaining to do so? The stakes get far higher at high order levels.

We were contacted by Andy from IVI 3D, who attempts to explain how they are able to produce the machine at such a low cost:

“First, we use low cost extruded aluminum

Typically, the costs for mold production are high and a large output quantity is needed to ensure manufacturing is financially viable.

To reduce the cost we developed a manufacturing plan in which the most costly and critical parts of the machine are completed with only two simple molds (far fewer than would normally be required for such a complex machine.) Not only can these two molds produce the lion’s share of the frame, they do it all with exceptional precision and reliability.

We sacrifice our margin

As a team, we have countless 3D printing ideas and designs. Some of them have been realized in IVI, some have not. From the beginning of this journey, we didn’t see IVI as a one-off project, but as the start of a long-term journey. Crowdfunding IVI is only the first step. Our main goal is to get started and build brand awareness through crowdfunding. Once we have built momentum, we can concentrate not only on continuing IVI’s development, but on implementing our other ideas into future products.

Made in Shenzhen, China

While you might know it as the mysterious ‘Silicon Valley of Asia’, or ‘The world’s electronics factory’, to us it’s just home. We live not only in the city itself, but deep within the supply chains, the production lines, and the tech hubs. Together with a very good understanding of the local industrial ecosystem and help from experts with years of hands on experience in supply chain management, we have immediate and low-cost access to almost any component or product imaginable.”

This may be true; Shenzhen is a place where a great deal of very inexpensive equipment is produced. If you’ve ever explored Asian manufacturing distribution services like Alibaba, for example, you would know this to be true. Thus it is entirely possible that IVI 3D can do this.

It’s just that it has not been done before for a device offering as many functions.

While IVI 3D may be able to produce the hardware at scale, I am wondering about the software, which would necessarily be complex in order to handle all the different functions. In higher-level gear one can expect to have a relatively smooth user experience through the device’s software. But for a device at this cost level it may be too much to expect that. Developing fantastic software is very hard to do, and isn’t seen very often.

At this point it seems that IVI 3D has certainly overcome one barrier to success: obtaining funds. They’ve done that very well by attracting the orders. Now they’ll have to deliver.

We’re hoping the IVI 3D device doesn’t turn out like the defunct Buccaneer 3D printer, a product launched years ago — we actually saw it in person at one point — that failed miserably, leaving the backers without machine nor cash. Come to think of it, the IVI 3D printer and the old Buccaneer machine do have a bit of resemblance, don’t they?

Via Kickstarter and IVI 3D

FELIXprinters has released a new bioprinter, the FELIX BIOprinter, which is quite a change for the long-time 3D printer manufacturer.