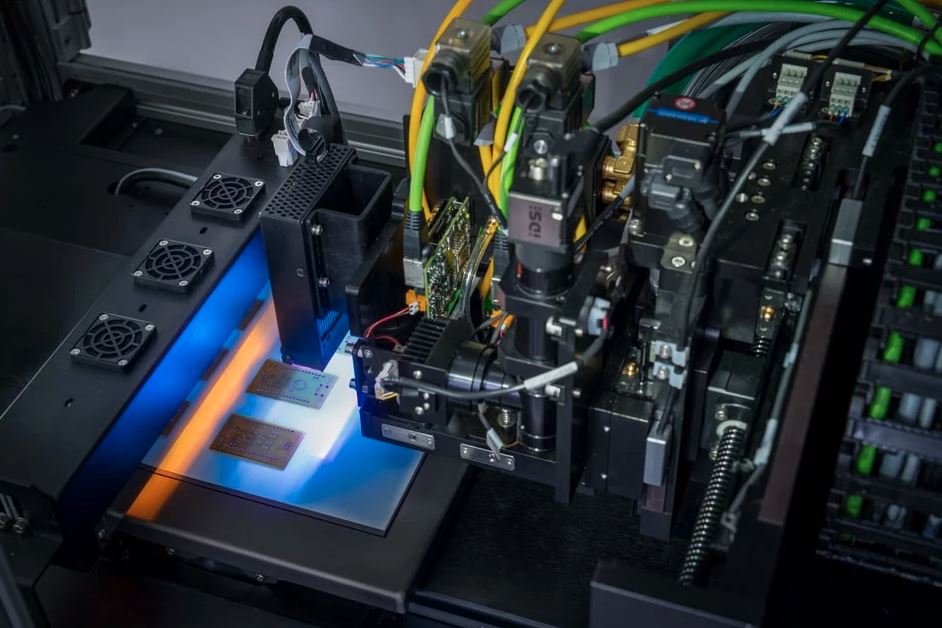

![Inside operations of the DragonFly LDM 3D printer [Image: Nano Dimension]](https://fabbaloo.com/wp-content/uploads/2020/05/NanoDimensionDragonFlyLDM1_img_5eb09360ab367.jpg)

True to its word, Nano Dimension has introduced a new DragonFly electronics 3D printer.

When last we heard from the Israeli company, the situation was looking a bit grim as underperforming financial results necessitated a strategic review and 20% staff layoffs.

When any company is in such a predicament, you can bet there’s also a move to put a shine on the news with something new to look forward to, and so it was for Nano Dimension. The company noted that it would soon be introducing a new system to its portfolio and, just two weeks later, that new system has been unveiled.

DragonFly LDM

Promising productivity and continuous operation, the new DragonFly LDM relies on Lights-Out Digital Manufacturing (LDM), which Nano Dimension defines as:

“[A] manufacturing methodology in which systems run with little to no human intervention, around the clock. In the case of additive manufacturing, LDM means DragonFly users can 3D-print more functioning electronic circuitry faster, extending the DragonFly’s rapid prototyping capabilities and increasing opportunities for short-run, small volume manufacturing of printed electronics.”

The introduction isn’t a simple unveiling, but is the announcement of a ready-to-order product: the DragonFly LDM is available now as either a new investment or an upgrade to an installed DragonFly Pro 3D printer.

As the upgradeability indicates, the LDM represents a next-generation improvement from its predecessor. It has also already seen its first installation in Munich with defence and security electronics company HENSOLDT, running in an applications area Nano Dimension has told us is in focus.

“The DragonFly LDM is a necessary evolutionary setup up from the DragonFly Pro, enabling low-volume manufacturing of electronic circuits fast and easy to do in-house, with minimal operator time,” said Andreas Salomon, responsible project leader for 3D printed electronics at HENSOLDT.

Capabilities

![HENSOLDT ALM project manager Andreas Salomon (left) and Nano Dimension’s Director Sales EMEA Valentin Storz with first PCB output. [Image: Nano Dimension]](https://fabbaloo.com/wp-content/uploads/2020/05/DragonFlyLDM_img_5eb0936117954.jpg)

Nano Dimension remains focused on the 3D printing of electronics, and the DragonFly LDM continues this, with applications for both prototyping and low-volume production.

Unspecified technological improvements allow for “24/7 uninterrupted 3D printing,” as the new system’s name indicates. Also enhanced are printer head software management algorithms, which now include automatic print head self-cleaning every few hours; real-time automatic material monitoring; and optimization of Overall Equipment Effectiveness (OEE). The goal on the whole is to maximize uptime, through both constant operation and a reduced maintenance schedule that now comprises “typically just one weekly maintenance operation.”

Work with HENSOLDT, which has worked since 2016 with a DragonFly 3D printer, shows “more than 40% higher printing time” as compared to previous generations when generating reference circuits.

Essentially, the company notes among the DragonFly LDM’s features and benefits:

-

Long uninterrupted printing for increased uptime and improved yield

-

Supports 3D printed multilayer PCBs, capacitors, coils, sensors, antennas and more

-

Simpler and faster operation for minimal maintenance

-

New automatic printhead self-cleaning system

-

Offered also as an upgrade for existing DragonFly Pro users

Continuous Operation

The lights-out digital manufacturing focus is spot on with what we’re seeing in general in 3D printing today: more focus on production, on automation, on uptime.

More focus, in short, on the needs of manufacturing.

Operator intervention and required maintenance tend to lengthen any production process, so enhancing automation and uptime has been the goal for many 3D printing companies as the industry matures.

As the most prominent figure in the still-largely-untapped electronics 3D printing niche, Nano Dimension is leading the way for this market. The small electronics that power important systems in a variety of markets are often needed very quickly, so producing these rapidly and reliably is a must.

Nano Dimension Co-Founder and CEO Amit Dror notes that making the 3D printing of functional circuitry “more agile, faster, and affordable” was key to the design of the LDM system, along with ease of use — “making it possible for companies to be more innovative, improve productivity and reliability, lower costs and reduce time-to-market.”

Via Nano Dimension