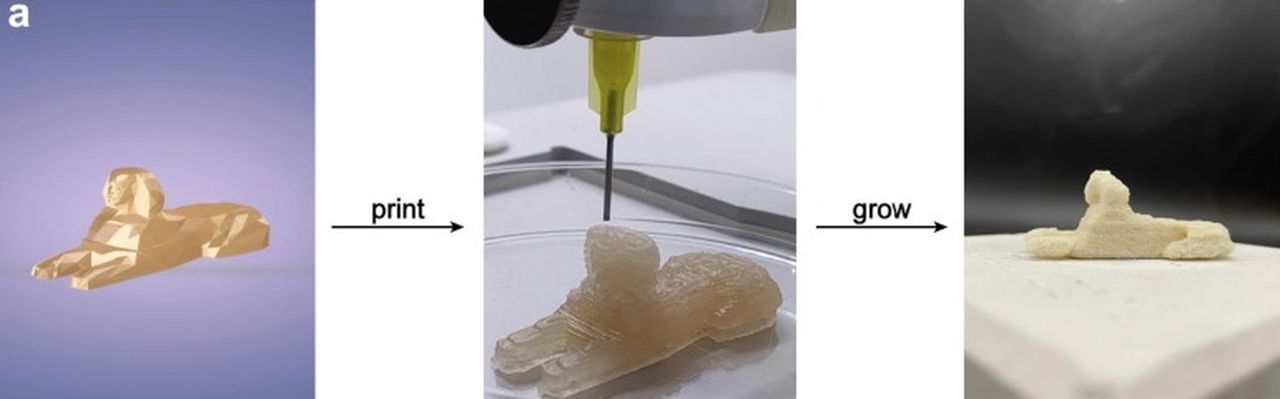

Researchers at EPFL Lausanne have discovered a technique to 3D print calcium carbonate using bacteria.

That may sound strange, but the new “BactoInk” can actually do this. Here’s how it works.

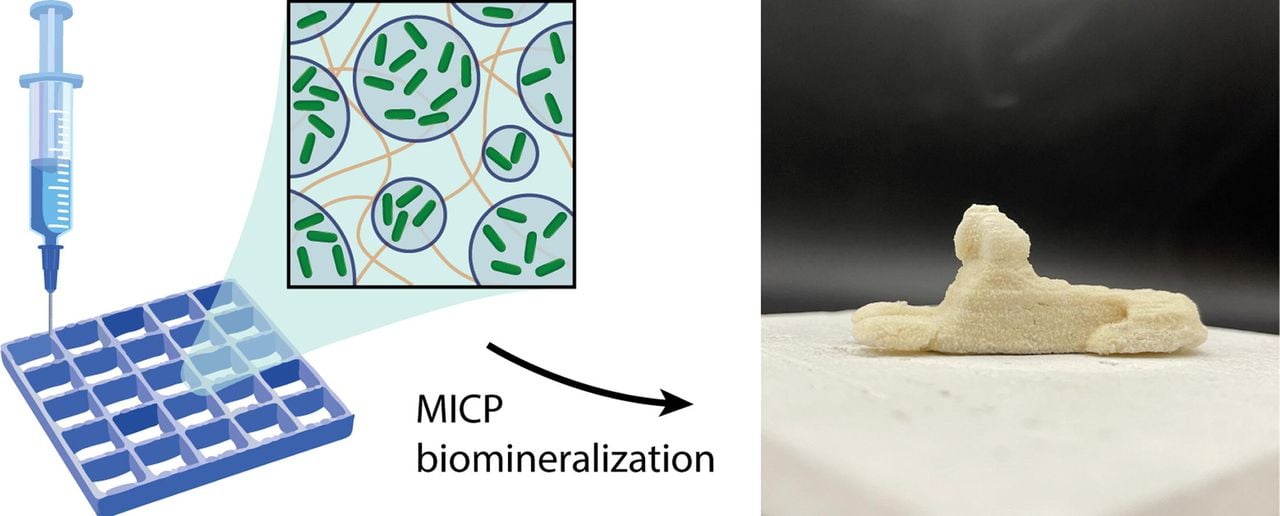

BactoInk is infused with a specific bacteria, Sporosarcina pasteurii. This particular bacteria has a very unusual property: if exposed to a urea solution, it will trigger a mineralization process and create calcium carbonate. Calcium carbonate is a major component of limestone and other rocks.

The second step occurs after printing, and can take up to four days to complete. Afterwards, the resulting structure is said to be 90% calcium carbonate. Basically, you can print limestone objects with this material.

The major development by the researchers was to find a way to print the loose bacteria such that the 3D structure would be stable. That enables the geometry to be maintained during the second step to transform the structure to calcium carbonate.

This is a notable development, as we have not previously seen a way to 3D print “rocks”. There have been multiple “mineral” filaments on the market — I’ve used a couple. These filaments are essentially a polymer mixed with rock dust, and they produce interesting and somewhat harder prints. But the polymer remains in the structure.

With BactoInk, it seems that you’re left with mostly rock.

An interesting side application for BactoInk is the ability to repair sculptures. It’s possible to inject a small amount of the material into cracks where it will form calcium carbonate when exposed to urea.

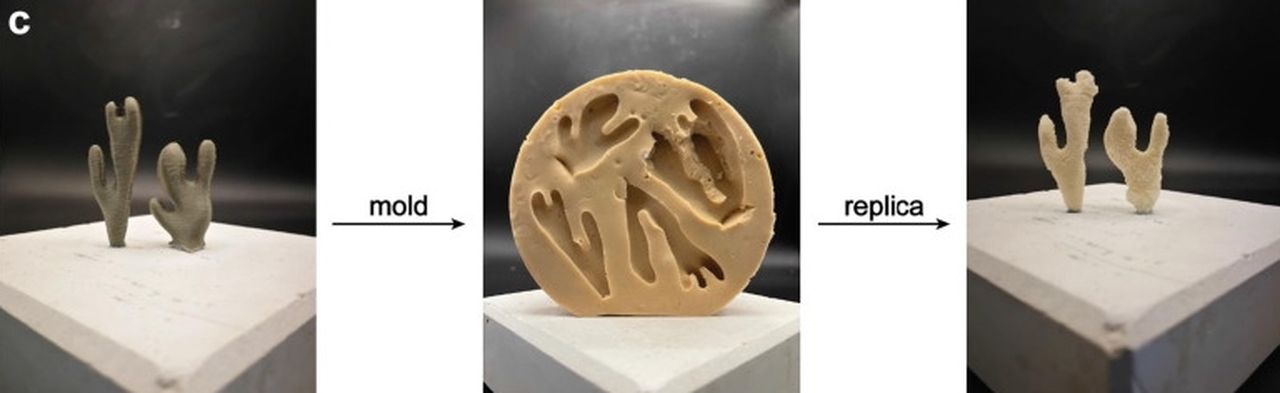

Another application for BactoInk is molding. It’s possible to 3D print a mold, which would transform into calcium as above. The strong, rock mold could then be used repeatedly to produce objects with softer materials.

Finally, I am wondering whether this material could be used in construction 3D printing. The examples produced by the researchers were all quite small, but does it scale up?

One could imagine a large-scale BactoInk printer printing a building out of stone.

I’m not sure how deep the urea solution can penetrate these prints, but if it’s substantial, then it could be possible to print stone buildings with a scaled-up version of the printer.

Via EPFL