Charles R. Goulding and Peter Favata look at how the solar panel industry could make use of 3D printing technology.

The first solar panels for powering buildings date back to 1973 at the University of Delaware.

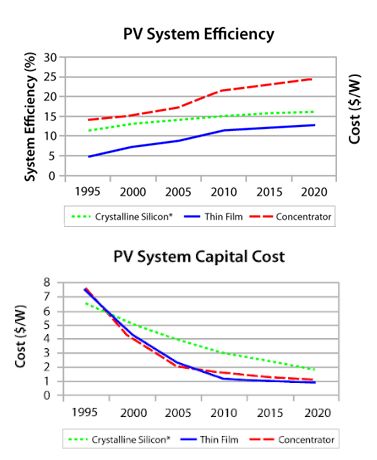

Since then solar has expanded to become the main power source for many homes across America. It is estimated that today around 2 million solar systems are installed around the U.S. Benefits of solar panels include reduced electricity bills, low maintenance costs, and it harnesses a renewable energy source, thus reducing dependence on fossil fuels. With advancements in technology, solar panels are now less expensive and more efficient than ever. Below is a graph depicting the changes in capital cost and system efficiency for three different PV cells over the years.

More Appealing With New Technology

Historically, people have refrained from installing home solar panels primarily due to the upfront cost and appearance. Luckily, right now is one of the best times to consider installing solar in your house. The federal government is offering a 26% tax credit of the total upfront cost of installing the panels to help encourage more people to start using green energy. In regards to a solution for the appearance, Tesla has developed solar panels that mimic roofing tiles. These tiles are three times stronger than standard roofing tiles while being able to handle hail, wind, and has the best fire rating available.

3D Printing

3D printing has been used in the manufacturing of solar panels. Designing new types of panels is a long process that consists of many different tests and prototypes. The way these tests are performed is by analyzing the solo cells that are embedded in the panels. Constructing these cells used to take hours to produce using traditional manufacturing methods. Now, using 3D printing, these cells can be manufactured in minutes allowing for faster testing, therefore more prototypes to analyze what works most efficiently.

Photovoltaic System Hardware

Photovoltaic systems require a wide variety of hardware to stay securely affixed on a roof. Fasteners, one of the most commonly used pieces of hardware in the solar industry, is a great candidate for 3D printing. 3D printed stainless steel hinges are just as strong as traditionally manufactured stainless steel and can be designed using CAD to securely fit any solar racking system perfectly.

MIT

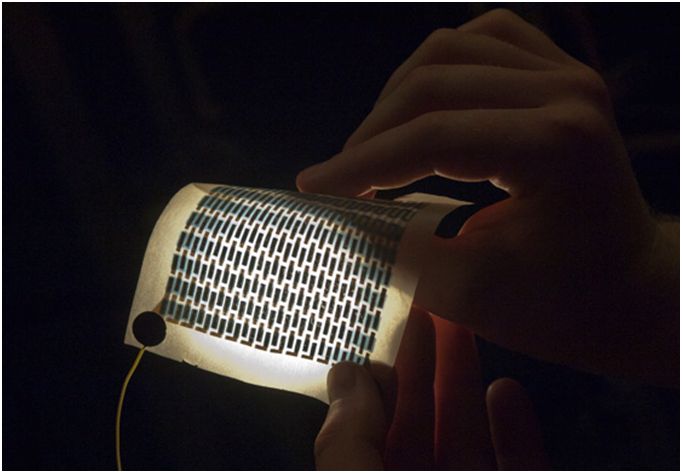

Massachusetts Institute of Technology (MIT) in Cambridge, Massachusetts has been engaging in 3D printing applications for PV research for decades. In 2011, a team of researchers at MIT have developed a process to print solar cells on untreated paper or plastic. This is done by printing five layers of material onto one sheet in consecutive passes, this must also be done in a vacuum chamber to make sure no air gets trapped or foreign objects interfere.

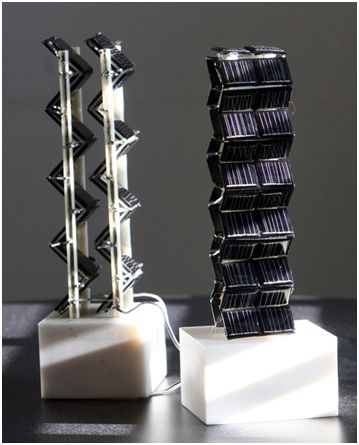

MIT has also developed more efficient ways to configure solar panels using 3D printing to prototype the models. By building cubes or towers that spread the solar cells upward, the power output ranged from double up to 20 times more efficient when compared to the traditional method of laying panels flat on a roof. The MIT researchers went through multiple iterations of 3D printed prototypes before concluding that this was the optimal design.

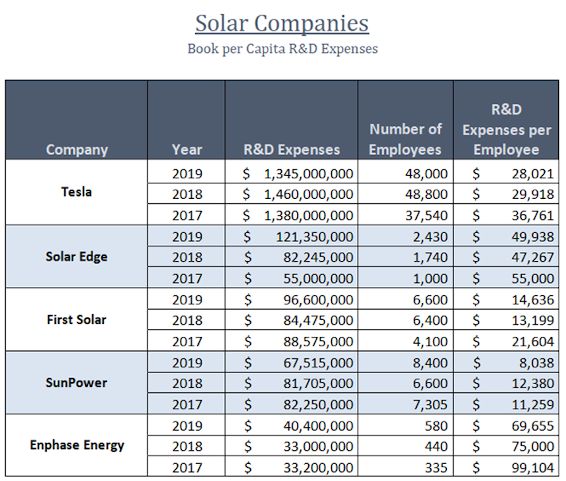

Manufacturers and technical designers utilizing 3D printing to develop solar technologies may be eligible for R&D Tax Credits. It is important to note that although companies do not need to be engaging in 3D printing activities to be eligible for R&D Tax Credits.

The Research & Development Tax Credit

Whether it’s used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D credit-eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Enacted in 1981, the now permanent Federal Research and Development (R&D) Tax Credit allows a credit that typically ranges from 4%-7% of eligible spending for new and improved products and processes. Qualified research must meet the following four criteria:

- Must be technological in nature

- Must be a component of the taxpayer’s business

- Must represent R&D in the experimental sense and generally includes all such costs related to the development or improvement of a product or process

- Must eliminate uncertainty through a process of experimentation that considers one or more alternatives

Eligible costs include US employee wages, cost of supplies consumed in the R&D process, cost of pre-production testing, US contract research expenses, and certain costs associated with developing a patent.

On December 18, 2015, President Obama signed the PATH Act, making the R&D Tax Credit permanent. Since 2016, the R&D credit can be used to offset Alternative Minimum Tax (AMT) or companies with revenue below $50MM and, startup businesses can obtain up to $250,000 per year in cash rebates that can be applied directly to payroll taxes.

Conclusion

With improvements in 3D printing solar panels, the technology is changing much faster than ever. Combined with lowering costs of installation and tax incentives, it would not be surprising to see many houses with solar panels in the near future.