Charles R. Goulding and Preeti Sulibhavi propose a 3D printing solution to the garage door supply chain problem.

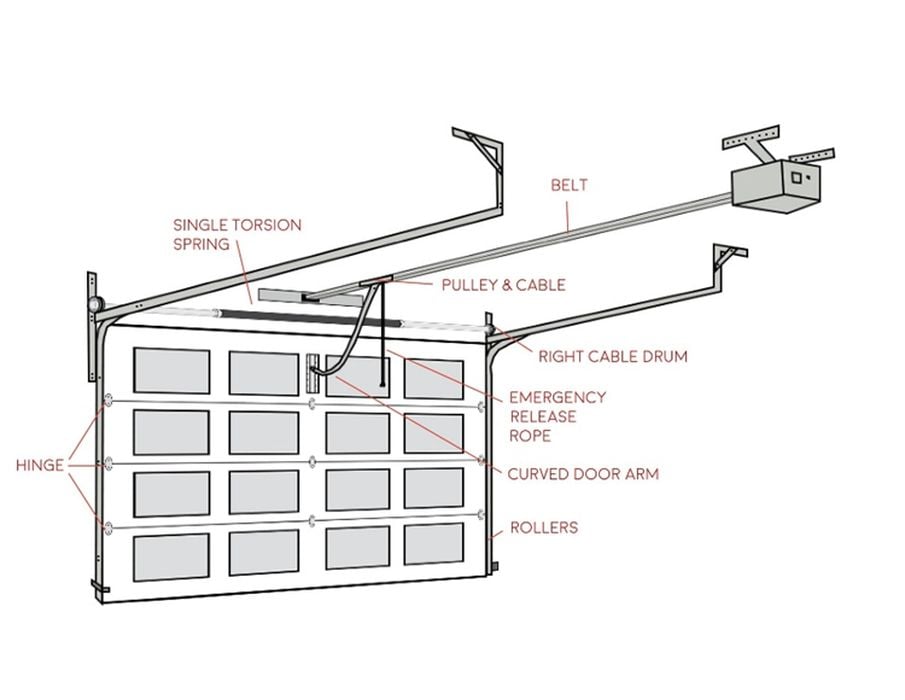

The United States is confronting a severe shortage of overhead garage doors which is disrupting a strong housing construction market. Overhead garage doors have a surprisingly complex component supply chain which is presented in part in the diagram below.

The supply chain shortage is so extreme that many new houses are being completed with temporary plywood garage opening coverings. Many of the underlying components of the garage door can be 3D printed enabling the industry supply chain to be improved and simplified.

KB Homes, the national home builder, stated they are adding suppliers for garage doors and other components that have more internal component capability. Interestingly, for appliances they are shifting to Whirlpool, which has extensive 3D printing component capability.

3D Printing

There are many examples of how 3D printing can be utilized in various overhead garage door component manufacturing and fabrication. Everything from emergency release system components to pulley and cables can be 3D printed today.

One Cults creator, FrozenRC, has designed a functioning prototype of an overhead garage door consisting mostly of 3D printed components that can be scaled to the appropriate size.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing, and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

Overhead garage doors have multiple components that can be 3D printed. Door suppliers that want to become preferred vendors should consider using 3D printers, evidencing greater internal capabilities.