Charles R. Goulding and Preeti Sulibhavi consider the spread of 3D printing parts for buses and other public transportation.

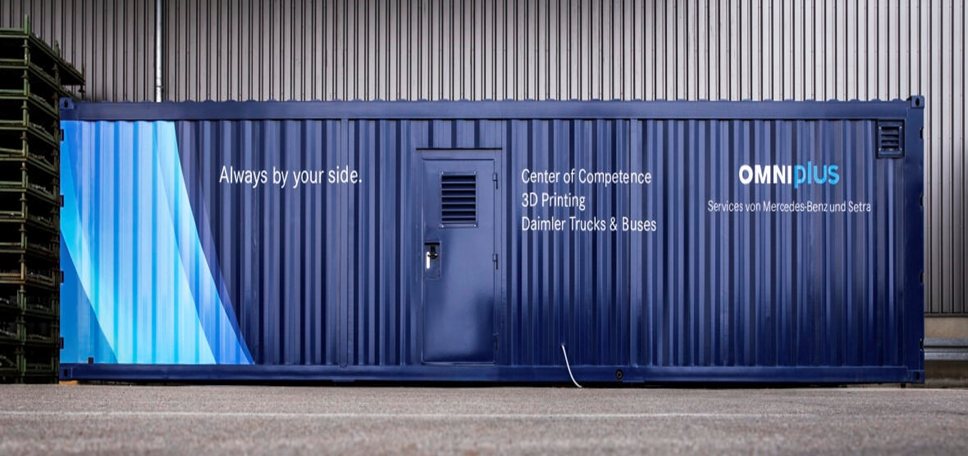

To facilitate and integrate the decentralized additive manufacturing of spare parts for transit and commercial buses, Daimler Buses and its Omniplus service brand have established a mobile 3D printing center. It is a mobile container and will be in operation at the BusWorld Home service center in Hamburg – but can be transported by truck to any location with only electricity and internet connection is required only when in operation. Daimler is doing this in hopes that spare parts are delivered to its bus customers expeditiously.

In fact, Daimler Buses has indicated it intends to further expand and decentralize the business model, with customers able to purchase 3D printing licenses from the ‘commerce’ section of the OMNIplus ON Portal and have corresponding parts produced in a 3D printer center, certified by Daimler Buses.

“Thanks to the mobile 3D printing centre, we can exploit the advantages of 3D printing to a greater extent and further increase the speed at which we supply spare parts. Decentralised production of parts as required avoids warehousing costs and reduces transportation routes. Thus, 3D printing not only allows us to react fast, flexibly and economically to customer requirements but to also improve our ecological footprint for the production of spare parts,” says Bernd Mack, Head of Customer Services & Parts at Daimler Buses.

Such ideas could translate well around the world. In the U.S., the largest bus depots include the New York City, New Jersey and Los Angeles transit authorities.

New York City MTA

The NYC Metropolitan Transportation Authority (MTA) is North America’s largest transportation network, serving 15.3 million riders across a 5,000-square-mile route surrounding NYC, Long Island and southeastern NYS as well as parts of Connecticut. The amount of buses and rail cars amounts to more than all other US transit systems have combined. The NYC MTA makes 8,200 weekday trips.

The NYC MTA has two major central maintenance facilities (CMFs) that serve the New York City area. They are the Grand Avenue Central Maintenance Facility, which is adjacent to the Grand Avenue Depot in Maspeth, Queens, and the Zerega Avenue Central Maintenance Facility, located at 750 Zerega Avenue in the Bronx. Both maintenance facilities are responsible for the major reconstruction of buses in need of repair including engine rebuilding, transmission shops, and shops for body components on New York City Transit Authority’s bus fleet, as well as the repainting of buses. In addition, Zerega Avenue CMF is responsible for the registry of new buses added to the fleet. The Zerega Avenue facility was opened in 2001, while the Grand Avenue facility was opened in 2007 with the bus depot.

Previously, the large repair shops of the East New York Depot served as the system’s sole central maintenance shops; as of May 2016, East New York is considered a third central maintenance facility.

New Jersey Transit

The NJ Transit or NJT, is a state-owned, public transportation system that serves New Jersey, and parts of New York and Pennsylvania. NJT’s operations are divided into three main classes: bus, rail, and light rail. The three classes are operated by three organized businesses: 1). NJ Transit Bus Operations, Inc, for buses, 2). Newark Light Rail, subsidiary NJ Transit Mercer, Inc. for buses around Trenton, and 3). NJ Transit Rail Operations, Inc. for commuter rail

NJT operates 871 bus routes with a fleet of 2,477 buses (leasing out the remainder to private operators). The Newark Light Rail is comprised of 20 light rail vehicles (with numerous other line runs being subsidized by NJT). In addition, the bus fleet includes buses purchased for other New Jersey operators. Covering a service area of 5,325 square miles, NJT is the largest statewide public transit system and the third-largest provider of bus, rail, and light rail transit by ridership in the United States.

Los Angeles Metro

The Los Angeles County Metropolitan Transportation Authority (also known as “Metro”, “MTA”, or “LACMTA”) operates a vast fleet of buses. As of September 2019, LA Metro has the third largest bus fleet in North America with 2,320 buses, third to New York City’s MTA and NJT. The LA Metro operates the nation’s largest fleet of compressed natural gas-powered buses.

The LA Metro is also a major player in alternative fuel technologies, notably compressed natural gas (CNG). The CNG fleet reduces emissions of particulates by 90%, carbon monoxide by 80%, and greenhouse gases by 20%. Alternative fuel buses have logged more than 450 million operating miles since 1993 – an industry record.

Commercial Bus Companies

In addition to public bus transportation, numerous commercial companies provide bus services as well. Below is a list of major commercial bus companies:

- Greyhound bus company

- Megabus bus company

- BoltBus bus company

- Lux Bus America bus company

- Vamoose bus company

- RedCoach bus company

- Jefferson Lines bus company

- Peter Pan bus company

- FlixBus bus company

The vast and expansive nature of the U.S. metro bus transit system only highlights the need for 3D printed repair and replacement parts in this industry in a timely and effective way.

The Research & Development Tax Credit

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Enacted in 1981, the now permanent Federal Research and Development (R&D) Tax Credit allows a credit that typically ranges from 4%-7% of eligible spending for new and improved products and processes. Qualified research must meet the following four criteria:

- Must be technological in nature

- Must be a component of the taxpayer’s business

- Must represent R&D in the experimental sense and generally includes all such costs related to the development or improvement of a product or process

- Must eliminate uncertainty through a process of experimentation that considers one or more alternatives

Eligible costs include U.S. employee wages, cost of supplies consumed in the R&D process, cost of pre-production testing, U.S. contract research expenses, and certain costs associated with developing a patent.

On December 18, 2015, President Obama signed the PATH Act, making the R&D Tax Credit permanent. Since 2016, the R&D credit has been used to offset Alternative Minimum Tax (AMT) for companies with revenue below $50MM and, startup businesses can obtain up to $250,000 per year in payroll tax cash rebates.

Conclusion

It is time to think outside the box. That is exactly why Daimler Buses and are bringing 3D printing to the customer to help solve their spare part and minor repair issues. We think this is great news for the transportation industry.