New research has developed a method of 3D printing in brilliant iridescent colors.

“Iridescent” means the object displays seemingly luminous colors that appear to shift as the angle of viewing changes. Examples of this effect can be see in certain butterfly wings, soap bubbles, certain seashells and some minerals. They are quite noticeable if you encounter them.

Meanwhile, the typical materials used in a 3D printer a not at all iridescent, and are downright bland. In fact, surveys I’ve seen in the past indicate the most popular colors of 3D printer filament are always white and black, followed by grey. Dull, indeed.

But what if you could 3D print in an iridescent color? It turns out this may become possible in the future, based on new research by Jeroen Sol of the Eindhoven Institute of Technology.

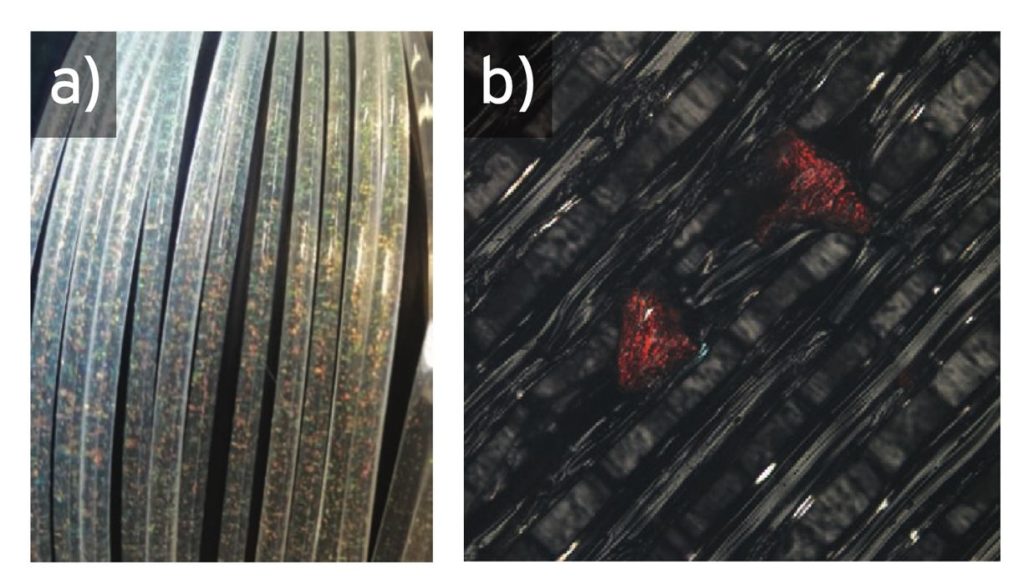

While most colors are produced by dyes absorbed by a material, iridescent colors are “structural”, as in they are part of the object. They tend to reflect polarized light, which is how the famous visual effects are generated. But could this effect be 3D printed? That’s the subject of a very detailed paper by Sol.

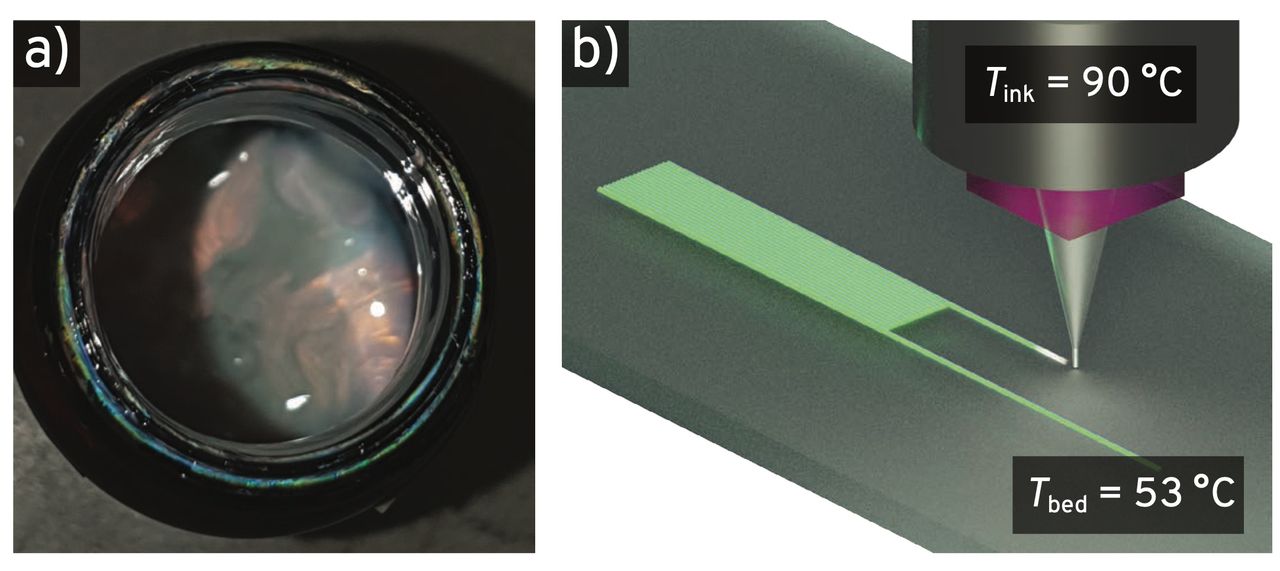

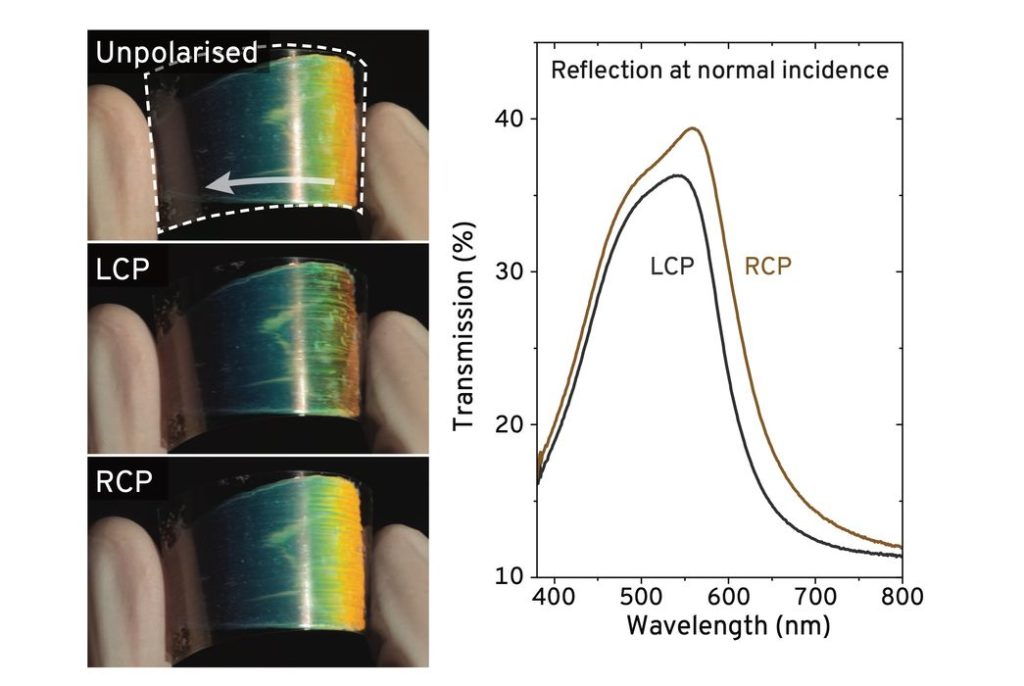

The approach used to achieve structurally colored photonics was to use a specially prepared liquid crystal, a ChLC oligomer ink. The paper explains:

“Is it possible to use a cholesteric oligomer ink with direct ink writing to print freeform structurally coloured objects, and retain the capacity of forming slanted cholesteric alignment? Based on the results shown in Chapter 3, that demonstrate a cholesteric oligomer ink which can be coaxed into forming a slanted photonic axis, direct ink writing is used to spatially program the unconventional cholesteric alignment.”

But it’s by far not as simple as that. It turns out the material must be aligned properly in order to achieve polarization:

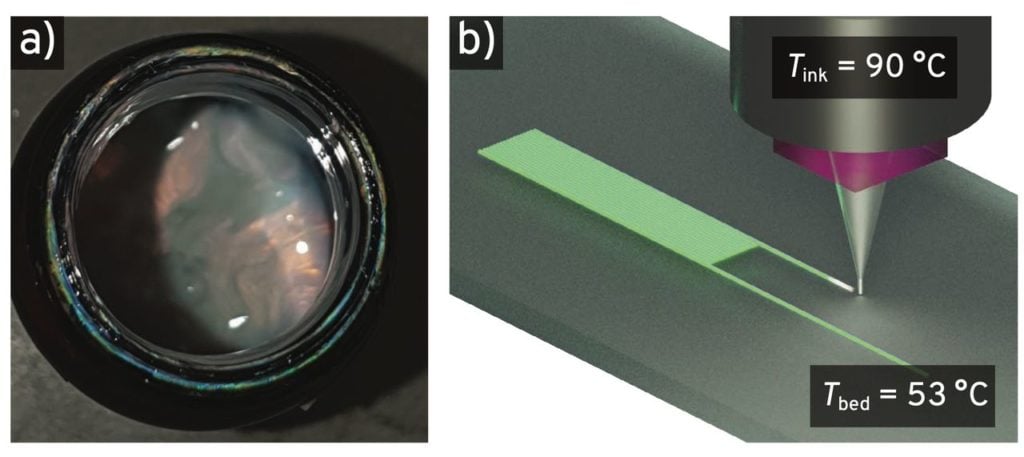

“Tuning the writing direction and speed leads to programmed formation of a slanted photonic axis which exhibits atypical iridescence and polarisation selectivity. After crosslinking, we obtain a freely-programmable, chiroptical photonic polymer material. The strongly perspective-dependent appearance of the material could function as specialised anti-counterfeit markers, as optical elements in decorative iridescent coatings, or as demonstrated here, in optically-based signalling features.”

Does it work? Apparently so:

“Visually, the material exhibits photonic reflection and manifests itself as a sticky paste similar to other LC oligomer mixtures, but with a clear structurally coloured property. Based on the results achieved in Chapter 3, we hypothesise that this ChLC oligomer ink is very well suited for generating bright, selectively reflecting prints using DIW.”

The research found that the speed of printing is a critical factor to achieving the structural color, which seems to affect the alignment of the molecules. They were also able to use this coloration even with standard voxel-by-voxel control of the print’s geometry. This suggests that it is entirely possible to 3D print objects with structural color.

The result, however is actually a film, rather than a fully solid object. That makes sense, as the structural color is only meaningful on the exterior of objects. The paper suggests that this technology could be used to, for example, place anti-counterfeiting tags on a 3D printed object:

“This chiroptical photonic ink, combined with the direct ink writing method used, pave the way for design of specialised polymeric optical elements with disparate optical effects, all deposited in one pass using the same ink. For instance, these could be written into anti-counterfeiting security tags, or printed directly into 4D printed soft robotic assemblies to embed optical sensing capabilities, a feature not widespread yet. Finally, the prints could be used for high-end decorative elements given the material’s attractive and uniquely iridescent appearance.”

There are many more details of this highly complex research available in the paper linked below. For now, it’s only research, but knowing that it is possible means that eventually it could be commercialized.

Via TUE (PDF)