6K announced a huge US$51M investment raise, allow them to triple their capacity.

The company is noted for its unique UniMelt microwave process for producing high-quality metal powder suitable for use in PBF metal 3D printers.

UniMelt Process

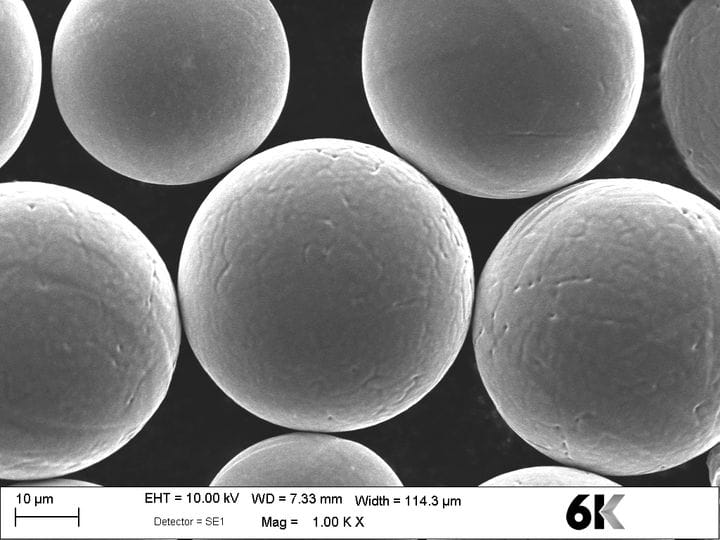

UniMelt involves a highly-tuned microwave system that creates a 6,000K plasma — hence the company’s name. This plasma, as hot as the surface of our Sun, is able to very quickly and efficiently process raw material into uniformly formed metal spheres.

That’s the key to metal powder production: uniformity. If the metal particles are of consistent shape and diameter, the resulting metal 3D prints can be correspondingly accurate.

UniMelt is unique among powder-making processes for another reason: efficiency.

Traditional methods of producing metal powder are actually quite wasteful in terms of resources. Significant amounts of water and energy are consumed in these processes, and a considerable amount of waste metal cannot be used. After harvesting the usable powder from a traditional powder-making process, there is usually a large pile of unusable material beside the production facility.

UniMelt is quite different, in that it can easily accept many types of metal scrap and immediately process them into high-quality metal powder for additive manufacturing. It’s even possible to restore “bad” powder by using it as input material to the UniMelt process.

UniMelt Alloys

Finally, one property of UniMelt that will no doubt prove extremely attractive to additive manufacturing is its ability to produce unusual alloys by combining arbitrary materials in the plasma. They say they can produce literally “any ratio” of input materials. I saw an “impossible” metal cube made of an alloy of six different metals, so their process definitely works.

The company has been on the move, setting up production facilities and striking a deal with Relativity Space for material production.

6K Investments

Now they’ve acquired a massive investment to power the operation forward at even greater speed. US$51M has been raised from a group led by Volta Energy Technologies with others. The primary interest of these investors is in battery production, something 6K is working on through their 6K Energy division. This investment is in addition to a previous near US$30M raised in other rounds.

However, the investment will also benefit the 6K Additive division, which intends on tripling their production capacity. They explain:

“Following the commissioning of its 45-acre ISO9001 24/7 state-of-the-art powder production operations in 2020, 6K will now expand production with an additional 600 tons/year and set up sales and distribution in Europe and Asia.”

For metal 3D printing operations, this is good news. New regions will gain access to 6K’s high-quality materials, plus the bonus of being able to use unusual alloys in a far easier fashion.

If you think 600 tons might not sound like a lot of material, think again. Metal powder for additive manufacturing can be particularly expensive, especially if it is of high quality, as 6K’s would be. Prices of US$500 per kg are not unheard of for some metals, suggesting that the production gain could be worth up to US$300M per year.

It’s no wonder this group chose to invest in 6K.

Via 6K