We were finally able to witness volumetric 3D printing in person.

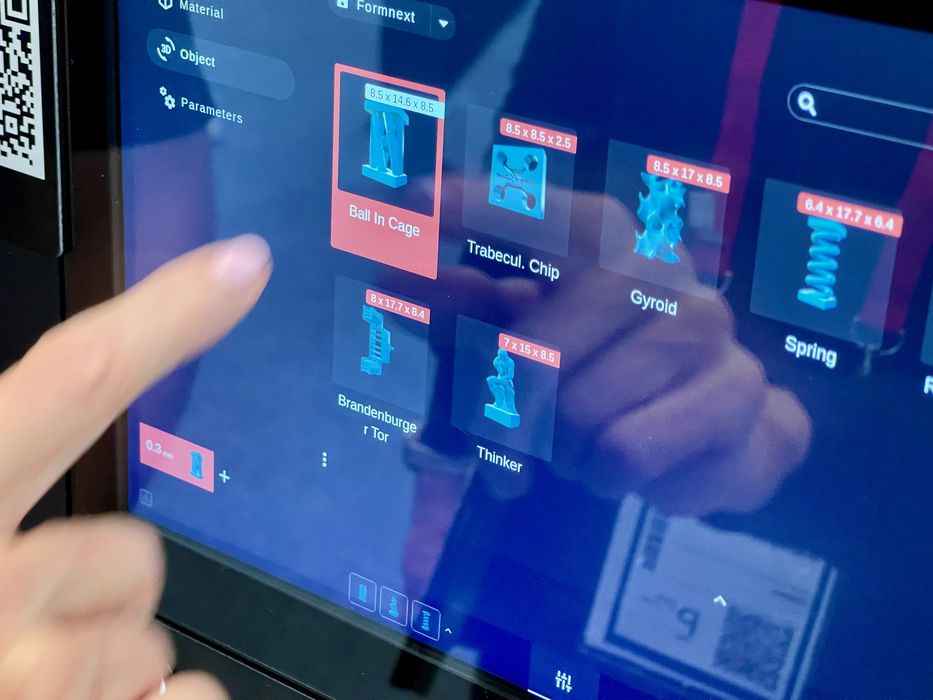

At Formnext xolo presented their device, the xube. As far as we know, it’s the first volumetric 3D printer on the market.

Wait, what is a volumetric 3D printer again? It’s a device that produces a 3D print but not layer-by-layer as every other 3D printer does. Instead a seemingly magical process takes place that prints the model all at once in a transparent cylinder of resin.

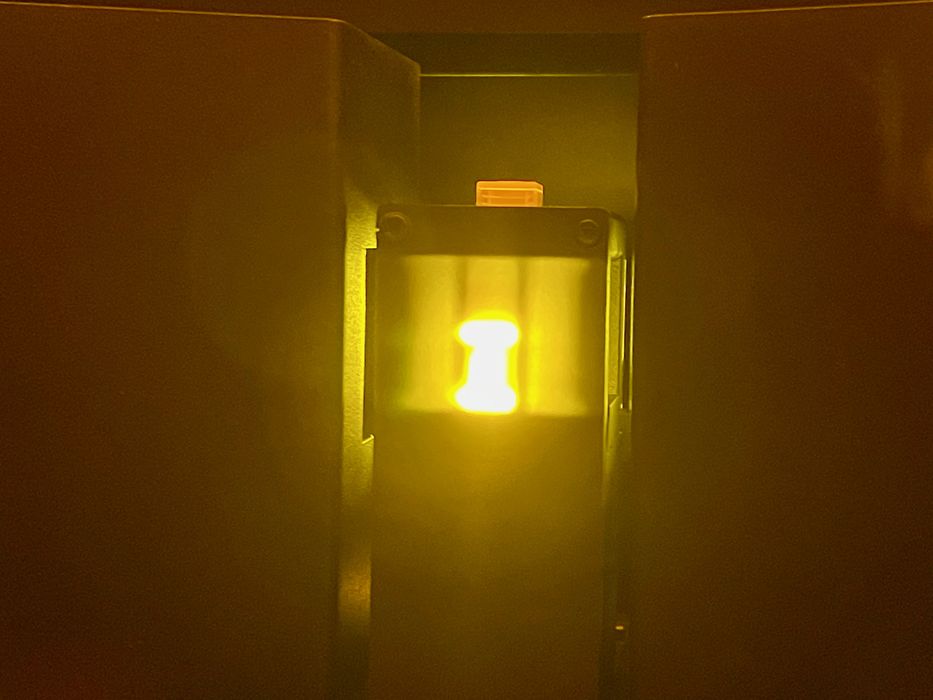

How can that possibly work? Volumetric 3D printers perform a kind of “reverse CT scan” where energy is projected into the vat from all angles, typically by rotating the vat. As energy is absorbed slowly in 3D space, the voxels gradually form.

The process is still mainly experimental, but promises to print objects at unbelievable speeds, sometimes estimated at 100X typical 3D printer speeds.

Now we were able to see this process in person.

The xube, shown at top is not a very large device, and that’s because the print volume of the device is also very small. So far the technology only works in small areas because the light rays have to penetrate all the way through the resin.

We were told the xube could print us a sample while we waited — because the process is so rapid.

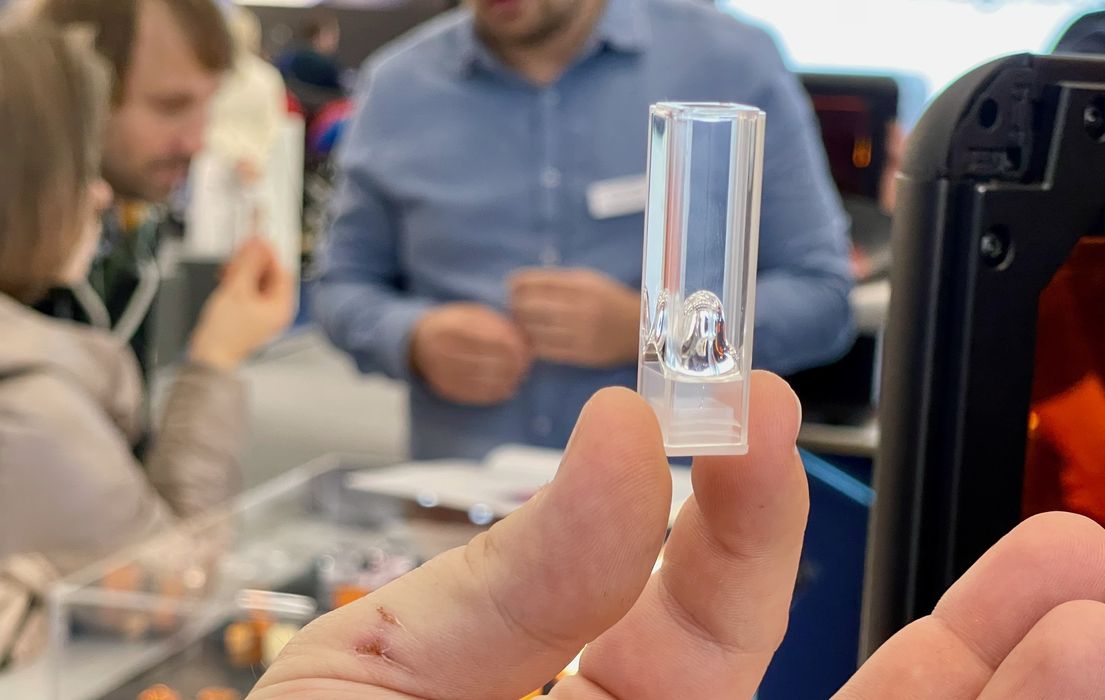

The printing takes place in a rather small clear glass tube filled with resin. This is inserted into the printer, and then the print begins.

It was an amazing process that took only a couple of minutes. A very bright light appeared in the build chamber — there’s a window where you can watch the operations. But really, all you see is a very bright light. There’s no layers appearing.

Then, even before we could finish a quick conversation, the print was complete. The tube was removed from the printer and this is what we saw: a complete 3D print made in record time.

The process definitely works, but you do need to wash and cure the print, much like other resin prints.

I asked about the scalability of the process: could larger print volumes be achieved? Currently they are able to achieve depths of up to 10cm.

The answer was that they aren’t working on that at this time because they’ve discovered so many applications for smaller objects. One application area seems to be dental prints. I presume the idea here is that the extreme speed of the system would permit near-instantaneous dental models made while the patient is still in the chair.

I’m hoping that xolo or another company in the volumetric space does develop larger-scale capabilities, as that would make for a very significant shift in technology.

Reflecting on what we saw was profound. Someone pressed a button. A brilliant light was seen. Then, an object appeared.

That was by far the closest thing to a replicator I’ve ever seen.

It won’t be the last.

Via xolo