AirLogic is a project to 3D print circuits. Not electronic circuits, but pneumatic circuits.

This sounds incredibly strange, but in fact electronic circuits are simply paths for electrons to flow with switches and gates to control where they go. But what if you used something other than electrons?

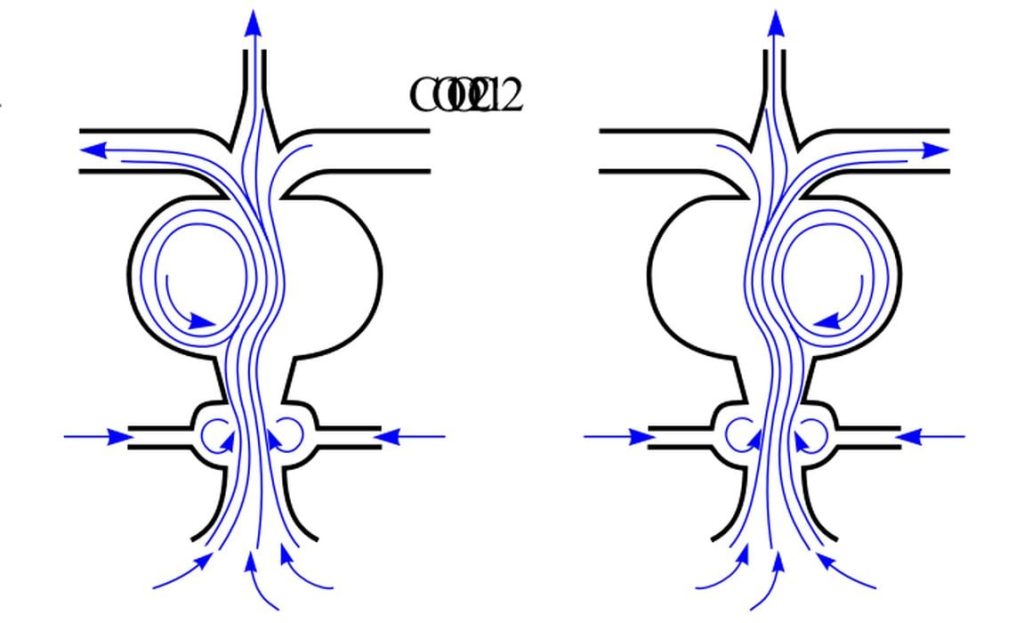

It’s entirely possible to create “circuits” using air instead of electrons. You just need to enclose the airflow and create “pneumatic switches”.

Don’t believe me? There’s a Wikipedia page explaining how this works. It’s the science of “Fluidics”.

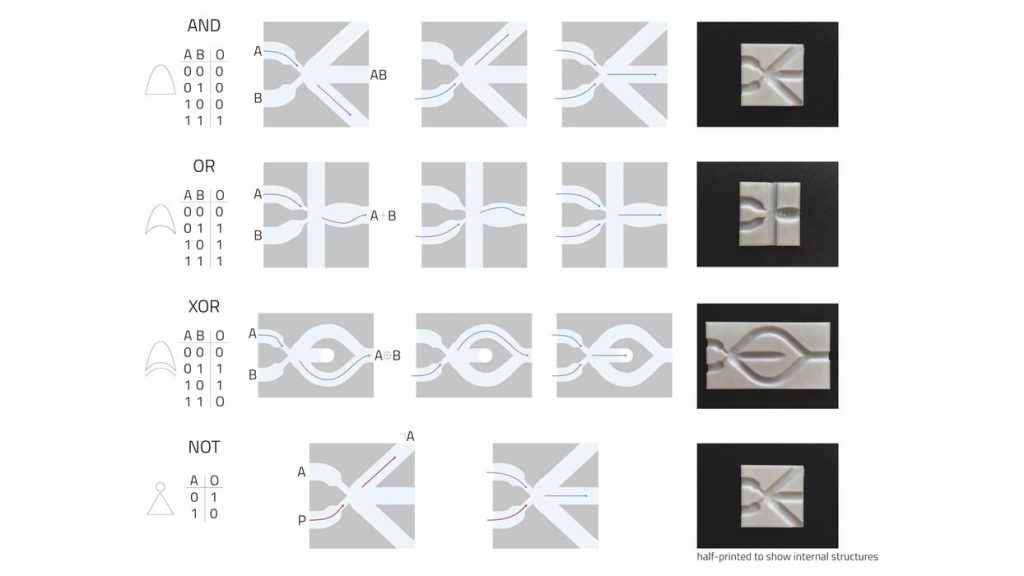

That’s exactly what a research project has done. Instead of “fluid”, they’re using “air”, which is the “fluid” of their “AirLogic” system. They designed a series of 3D printable pneumatic components that implement logic functions according to Fluidics principles.

These components, although they may appear to be simple tubes with curious curves, actually implement digital logic. In this chart you can see how the fundamental AND, OR, XOR, and NOT gates can be easily implemented with air flow:

These four logic gates can be combined to create any digital logic system. They are the most basic building blocks of today’s chips and computers. If you can build such things with electricity, then perhaps you can do the same with pneumatics.

This video from paper co-Author and Assistant Professor Valkyrie Savage, PhD at the University of Copenhagen shows how this all works:

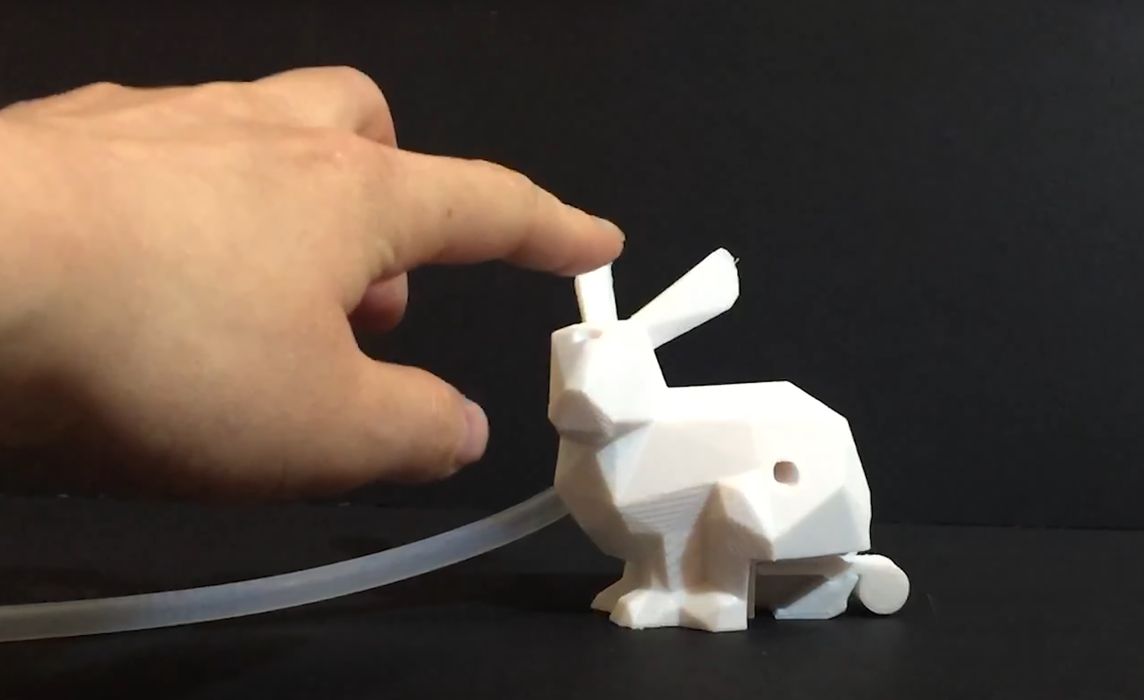

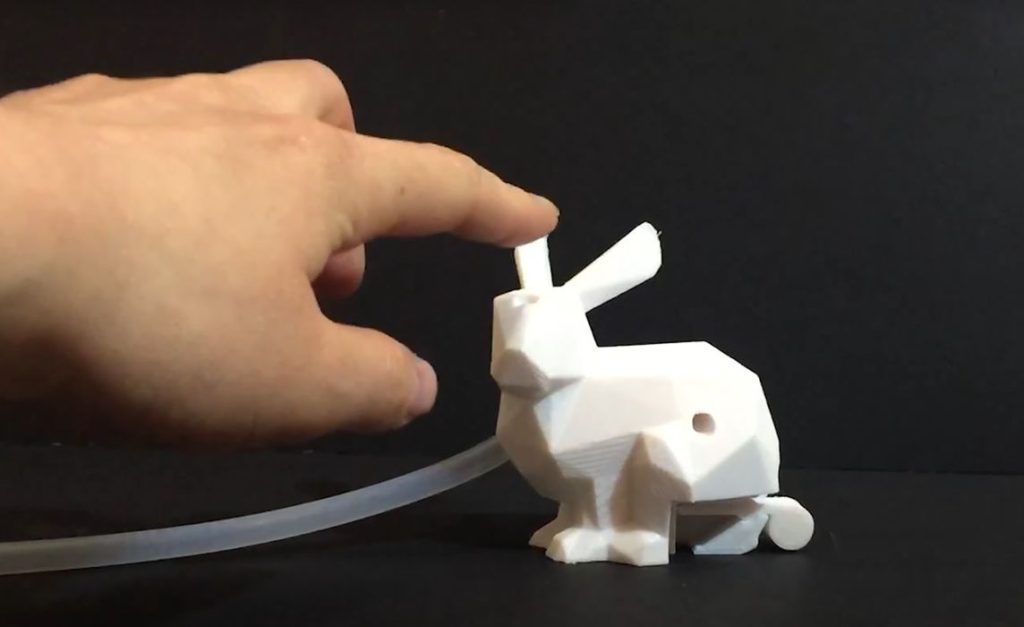

In the video there are several example applications of the 3D printed AirLogic system, including a bunny that wags its tail when patted on the head (see image at top). The research team implemented several other demonstration applications showing the potential of this technology.

There does not seem to be a repository online of these components, but it would be easy enough to replicate them if one desired to develop a pneumatic logic system.

One might ask why we would bother with pneumatic logic when electronic systems already have staggering capabilities.

The answer is that there are many extreme environments where electronics would be difficult or impossible to deploy. Any environment involving extreme heat would melt or otherwise corrupt traditional electronics. Similarly, high radiation environments are not welcoming to electronics.

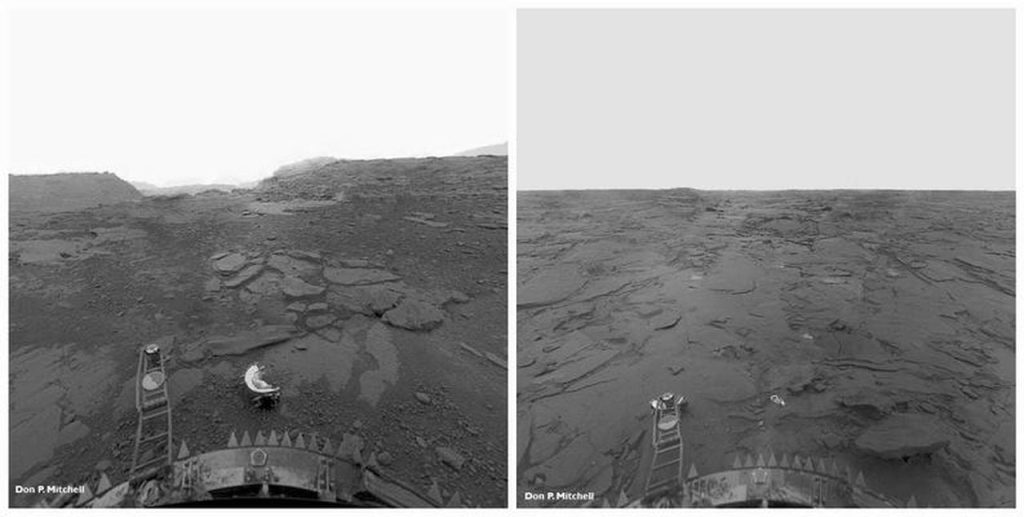

One particular application I could see for AirLogic technology could be for the exploration of the surface of sister planet Venus, which has a surface temperature of 450C, far above the melting point of many metals, in addition to an atmospheric pressure 100X that of Earth’s. Currently there is no way to implement logic on that planet’s surface except for very temporary cooling systems. But perhaps a pneumatic system could do so?

There are projects considering exactly how a surface system could exist in such an extreme environment, and perhaps AirLogic’s pneumatic concepts could be implemented and survive.

In the meantime, there is a new world of pneumatic logic to explore with 3D printed components.

Via ACM