AMAREA Technology has developed a powerful new 3D printing process they call Multi Material Jetting, or “MMJ”.

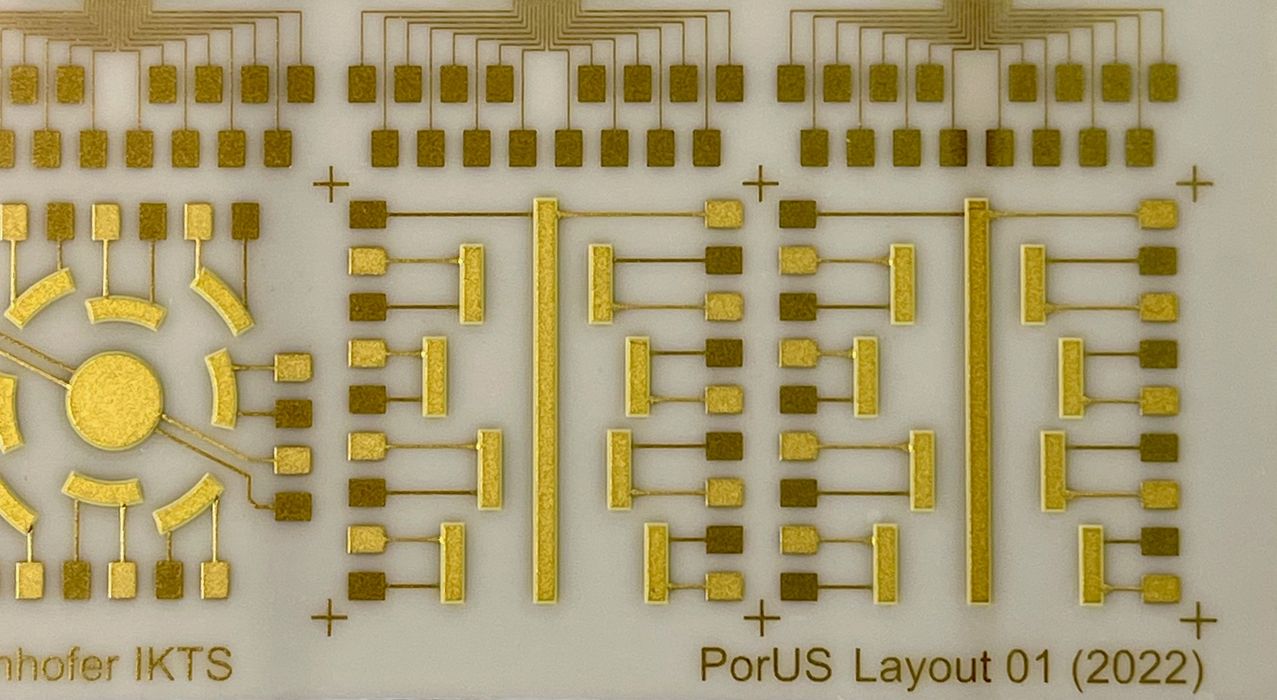

The German startup is a spin off of Fraunhofer IKTS, a frequent generator of new 3D print technologies. They were founded only in 2023, and plan to offer a 3D printer next year that uses the MMJ process.

How does MMJ work? It’s a variant of inkjet deposition, that can apparently “handle any material class”. That suggests it could potentially work with polymers, metals and ceramics.

The current implementation of MMJ involves three separate high resolution print heads that can selectively drop the materials. That implies a print could involve three different materials. Evidently the system can be expanded to up to six different materials.

The high performance material is said to be “like wax”, and the print head melts it to create droplets. The system is finely tuned so that the droplets solidify almost immediately upon dropping, meaning it’s possible to print quite rapidly.

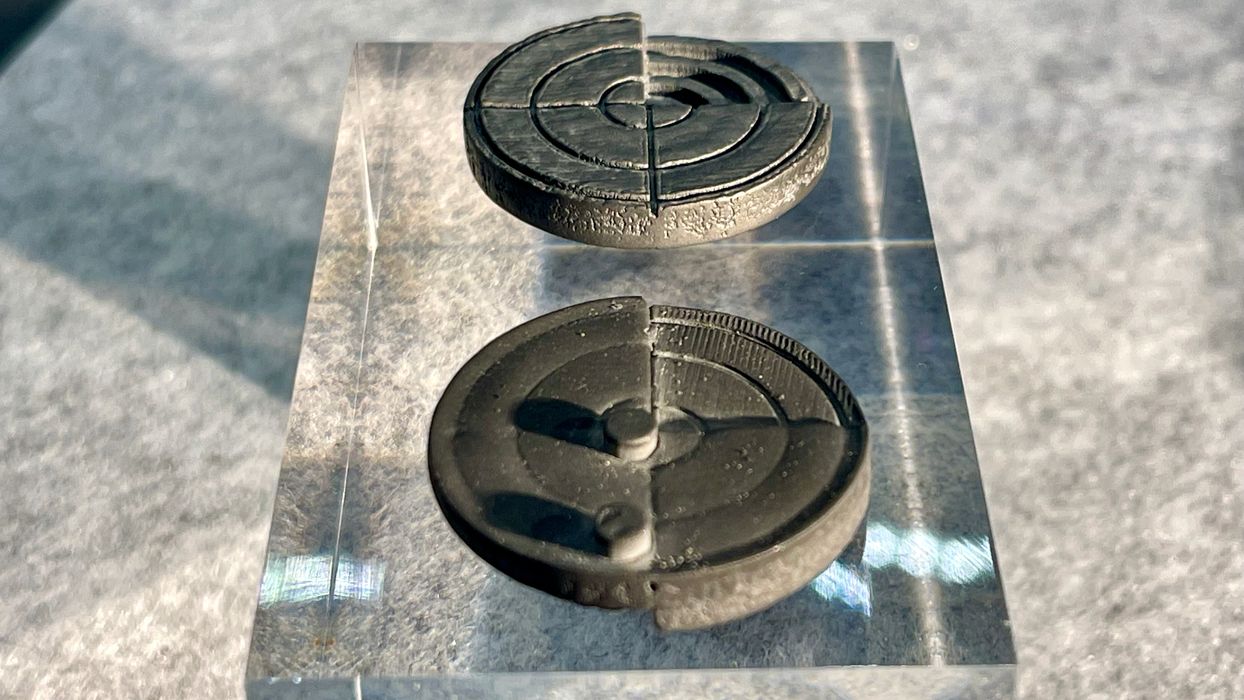

Another interesting advantage is that because the material is melted, the density of the parts is very high.

This produces a “green” part that must then undergo separate debinding and sintering services to complete the part. That’s quite similar to other “cold” printing processes.

However, the difference here is that there are potentially multiple materials involved. Jetted parts with multiple materials hasn’t been a thing because it is actually extremely difficult to achieve.

The main issue is that the different materials have different thermal profiles for debinding and sintering that can conflict. Prior attempts were not particularly successful, although we did see a print by XJET made with metal and ceramic a couple of years ago.

I challenged AMAERA representatives about this issue and they said they have a secret way to do the post processing. They have figured out combinations of materials that work with specific thermal profiles.

The company also is able to produce custom materials for MMJ in a kind of “bring your own powder” approach. Basically they figure out what wax ratio is required, and then they can produce the custom materials in only 14 days.

Currently they are working with some 25 materials including steel and some ceramics, but other materials are possible, even glass and precious metals. They also said that it’s possible to “screen print” electronic circuits on top of a print. I can imagine one of the materials being conductive to enable this capability: it’s just another material in the print.

For now the company offers print services using MMJ, but they expect to launch a 3D printer some time next year.

This week it was announced that Lithoz, a major producer of ceramic 3D printers, has taken a “strategic share” of AMAREA. That more than likely will provide the startup with a pile of cash to expand operations and get their product to market.

Via AMAREA

so objet never existed?

They do multimaterial jetting and material blending

3d systems has used multijet so long their patent expired. Granted they focused on nonmixed materials (support/build) but multimaterial jetting nonetheless.

The obstacle to this technology in the past wasnt complexity. It was a PATENT.

This process is able to print metal and ceramic, quite different from the polymer-only PolyJet process.