SPONSORED CONTENT

Anycubic released a pile of details for their tiny MicroLED 3D printer, which uses a very different light engine.

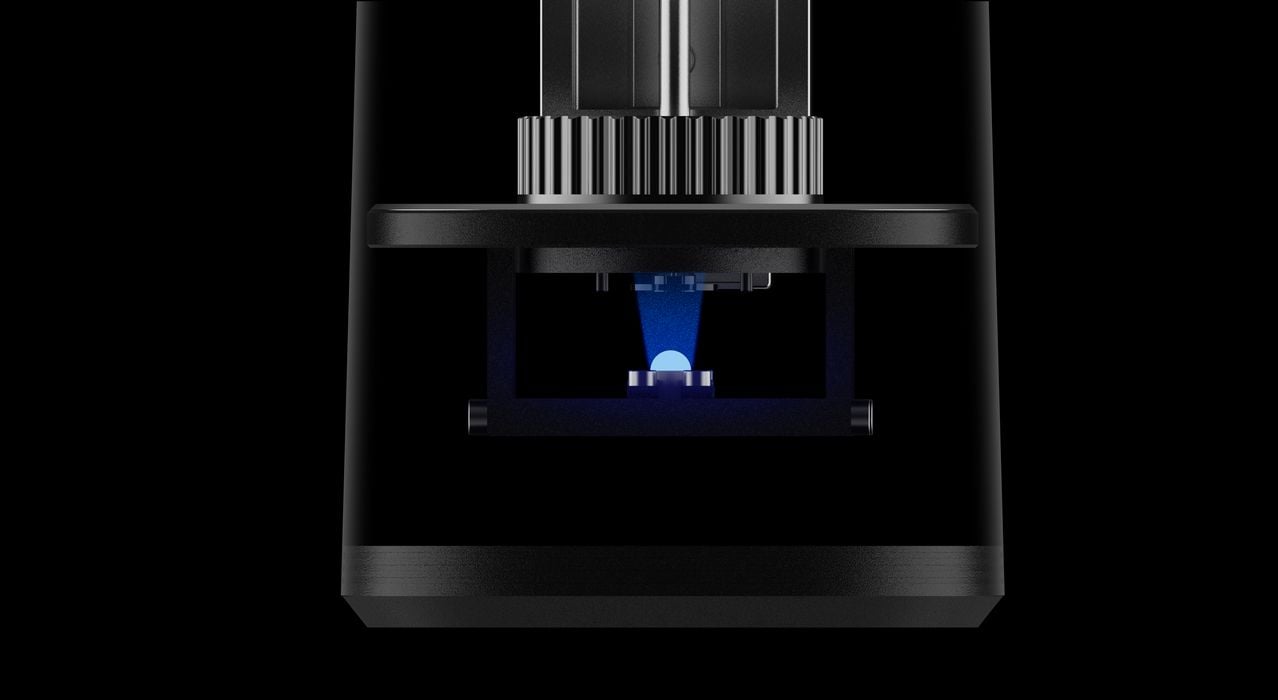

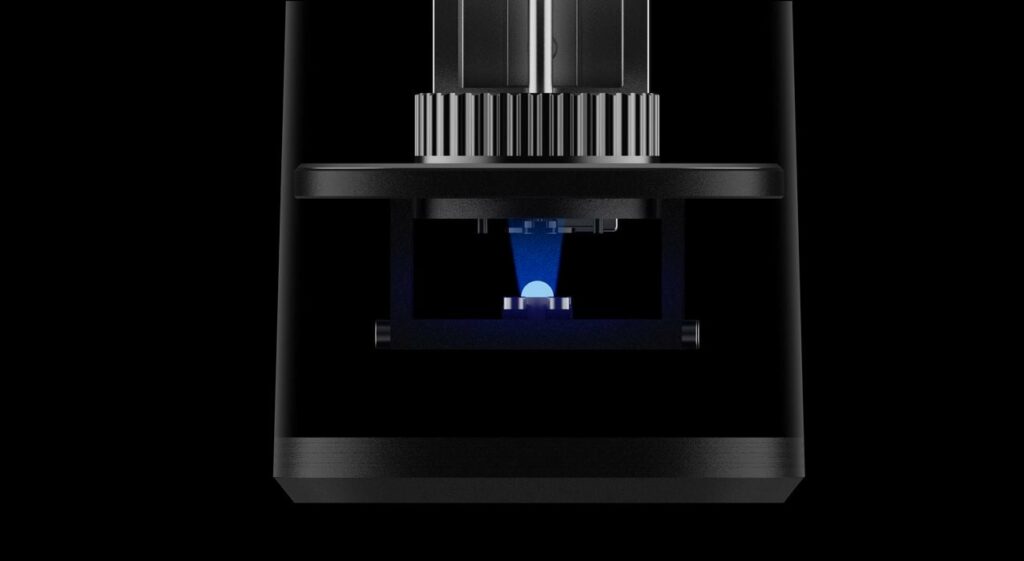

Anycubic is well-known for their resin 3D printers, which currently use either the standard MSLA (masked LCD panel) or DLP processes. However, the new device uses something quite different, a process we have not seen previously in any resin 3D printer: MicroLEDs.

MicroLED is a display technology that we’re starting to see in handheld devices, but this seems to be the first implementation of the technology in 3D printers. It’s basically an array of very tiny LED lights that can be individually controlled.

Unlike MSLA or DLP, the MicroLED array produces its own light and does not require anything other than some input energy to produce light. This should prove quite promising for use in resin 3D printers, and now Anycubic has made the first device using it.

Anycubic explains a bit more about this light engine:

”JBD’s MicroLED is an emerging flat-panel display technology and serves up ultra-high brightness, high contrast, high color gamut, low power consumption, etc. It is made of inorganic III-V light-emitting material LEDs and a silicon-based CMOS backplane. The crucial part of the MicroLED is the 0.13-inch ultraviolet (UV) light engine, which can contribute high contrast ratio and ultra-low power consumption to this MicroLED 3D printer.”

Last month Anycubic announced an upcoming 3D printer that was to use MicroLED technology, but there weren’t a lot of details about a prototype of the mysterious device, which is not quite yet an official product. Now, they’ve released quite a bit more information.

Anycubic has partnered with MicroLED manufacturer JBD to develop the new 3D printer, which coincidentally seems to be named the “Anycubic MicroLED 3D Printer”.

We already knew this device was incredibly small, as you can see in this image comparing the device to a standard 550ml drink can. It’s hard to imagine a 3D printer this small, but here we are.

Now we know more about the device, including its build volume: 6.4 x 4.8 x 30.0 mm.

I know what you are thinking: there is a typo in those figures. How could a build volume be less than 10mm on a side? Those are the correct figures, and the build volume of the Anycubic MicroLED 3D printer is indeed the size of the cap on a USB stick.

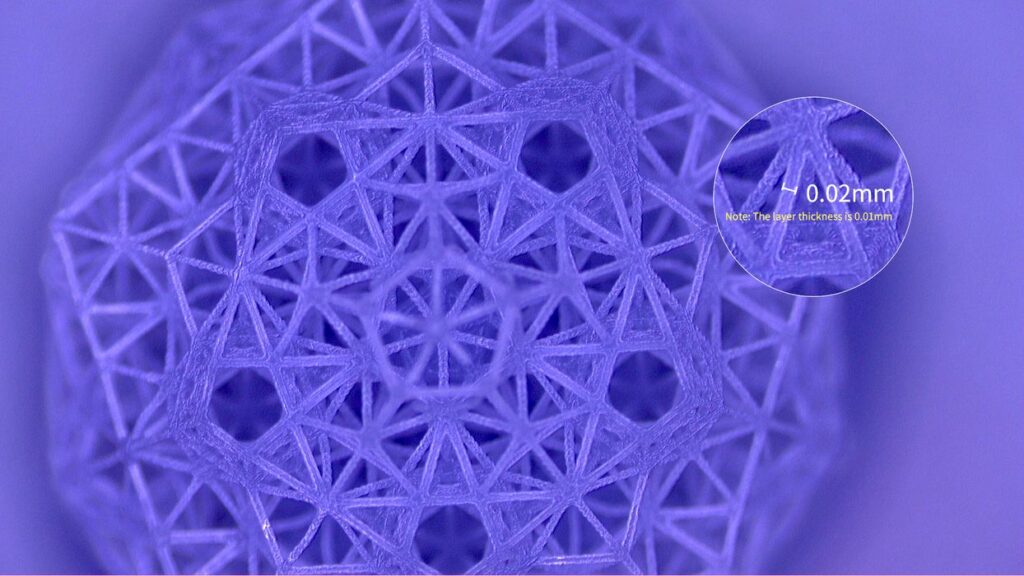

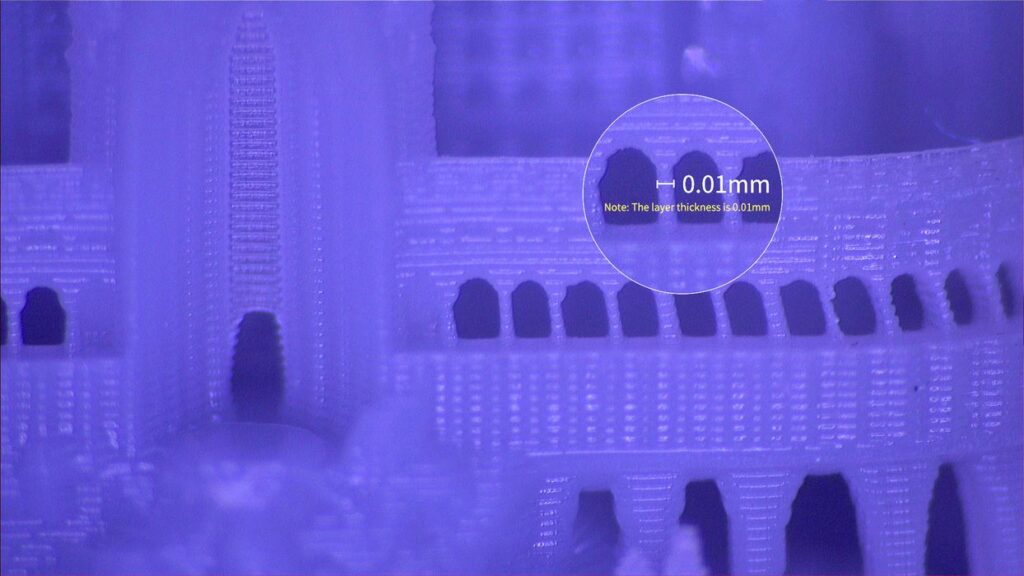

The interesting part is that the MicroLED light engine provides a massive amount of detail on this very small build volume. The display unit holds over 300,000 individual LEDs, all of which are squeezed into the 4.8 x 6.4 mm illumination area. Anycubic said the resolution is 640 x 480 pixels (307,200 pixels, exactly).

Imagine an image you’d look at on a computer monitor of 640 x 480. Now mentally shrink that down to a 5 x 6 mm area.

I think you can now understand the resolution of the Anycubic MicroLED 3D Printer. Anycubic said the pixel size on prints will be only 0.01mm across, resulting in more than 6000dpi resolution. Anycubic said the light engine can be focused to provide a range of resolutions.

The MicroLED 3D printer prints from the bottom, like typical MSLA and DLP 3D printers. However, because of the MicroLED technology, it will require only 6W of power to operate. This low power consumption keeps the device cool and it’s expected the light engine will last more than 20,000 hours.

Why build and sell a 3D printer with such an incredibly small build volume and high resolution? While you can certainly 3D print very tiny figurines and possibly some slim jewelry 3D models, the real application here is for industry.

With this extreme resolution it would be possible to 3D print tiny but highly complex structures for different applications. One application might be for complex fluid flow components, particularly in the healthcare or medical research sectors.

The Anycubic MicroLED 3D printer is certainly one of the most unusual devices we’ve seen. It’s anticipated the company will publicly display the device later this year.

Via Anycubic