Want to transform your Prusa 3D printer into a mini-factory? Enter “JobOx”.

One of the issues new 3D printer operators quickly realize is that 3D printers can only print one item. That is, until you clean them off the build plate so that a second and subsequent jobs can be run.

This is quite different from a 2D printer, which has a tray to catch any paper that is printed. In those machines you can merrily print as many jobs as you want, and they all go to the printer and are processed. The results are stacked together for pickup.

Not so on most of today’s desktop 3D printers, where operator intervention is absolutely required between each and every job.

If there was some way to automatically remove prints between jobs, then the machines could in theory run continuously and produce large quantities of parts.

There are a number of solutions for this problem already available, including advanced print plate technology, robotic systems or mechanical pushing.

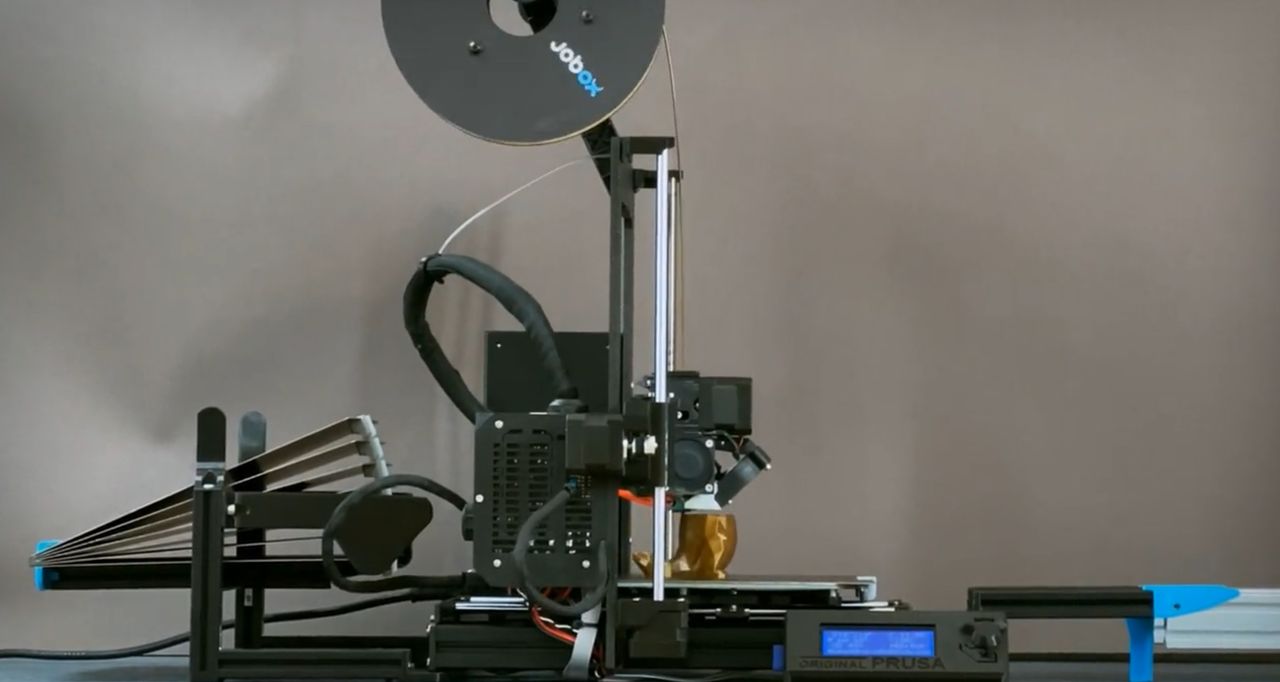

One solution that’s appeared is the JobOx, a system designed for the popular Prusa MK3S+ 3D printers.

Originally released as a Kickstarter last year, the JobOx is a system designed to automatically swap print plates on the Prusa. When a new plate is installed, a new job can be started — all without human intervention.

The design of the JobOx is ingenious: there are no electronics required, and it runs solely off of GCODE instructions. The printer’s firmware is unchanged, and neither is its hardware.

How does it work? It involves attaching a framework to the back of the Prusa which holds a set of print plates, ready for new jobs.

After a print proceeds, specialized GCODE drives the printer to perform a maneuver that pushes out the old print plate and pulls in one from the stack. After this is done, a new job can commence.

For continuous 3D printing, the collection of print plates can handle several jobs, and it’s likely the operator would have to deal with the completed jobs only once a day, depending on the length of the print job. Labor should be reduced because the prints can all be removed at once.

For job dispatch it would be a simple matter of simply pasting extra copies of the GCODE together, allowing one “job” to become multiple jobs as each plate is switched.

This is a very ingenious solution, and it’s not that expensive. The automation system is priced at €229 (US$248), and print plates are €35 (US$38) each.

In their Kickstarter video, they show the system using eight plates. This means that to duplicate that configuration, you’d pay about US$528.

That’s a fair bit of cash, and about half the price of the printer itself. On the other hand, the automation will dramatically increase print throughput and effectively make one machine seem like two are operating. In other words, in some situations the cost could be justified.

As Urbanmaker says, “your 3D printer is waiting for you more than you wait for your 3D printer.”

They are correct, and have a solution.

Via Urbanmaker (Hat tip to Tina)