BCN3D announced an entirely new 3D printing process using resin, Viscous Lithography Manufacturing, or “VLM”.

This is quite a surprise as the Spanish company has up to now focused primarily on FFF technology. Evidently they’ve been working on VLM for the last three years behind the scenes, and today they have unveiled it to the public for the first time.

VLM Overview

VLM is a 3D printing process that uses photopolymer resin, UV curing light and transparent film. That may sound identical to today’s inexpensive 3D printing processes, but VLM operates very differently.

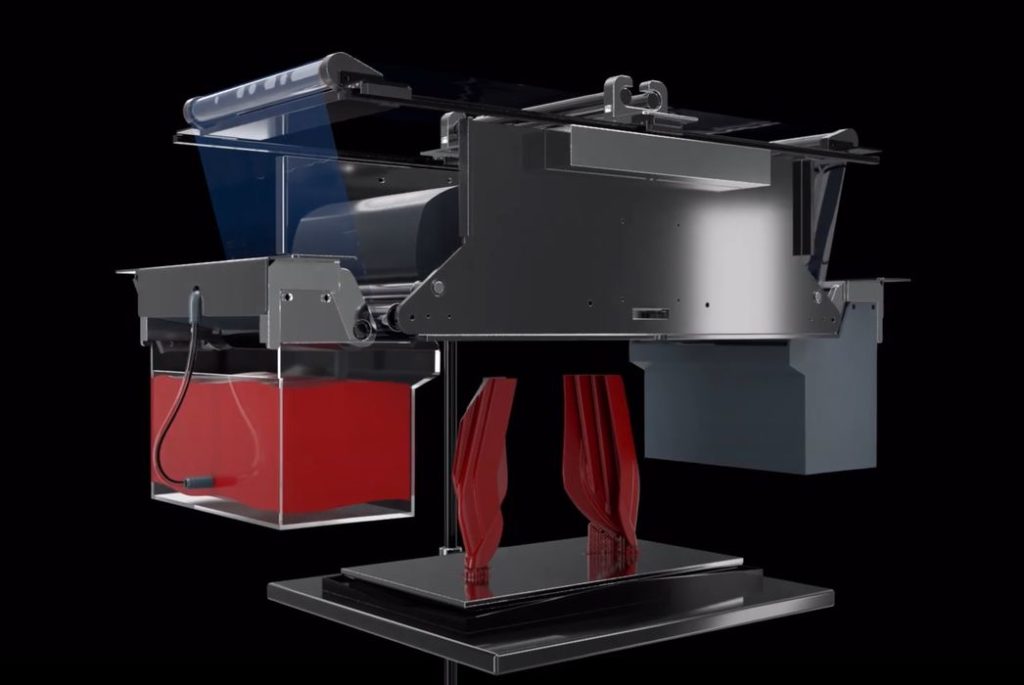

Whereas most current resin systems use a vat of resin, VLM simply uses a film. Here’s the sequence of events required to print a single layer in VLM:

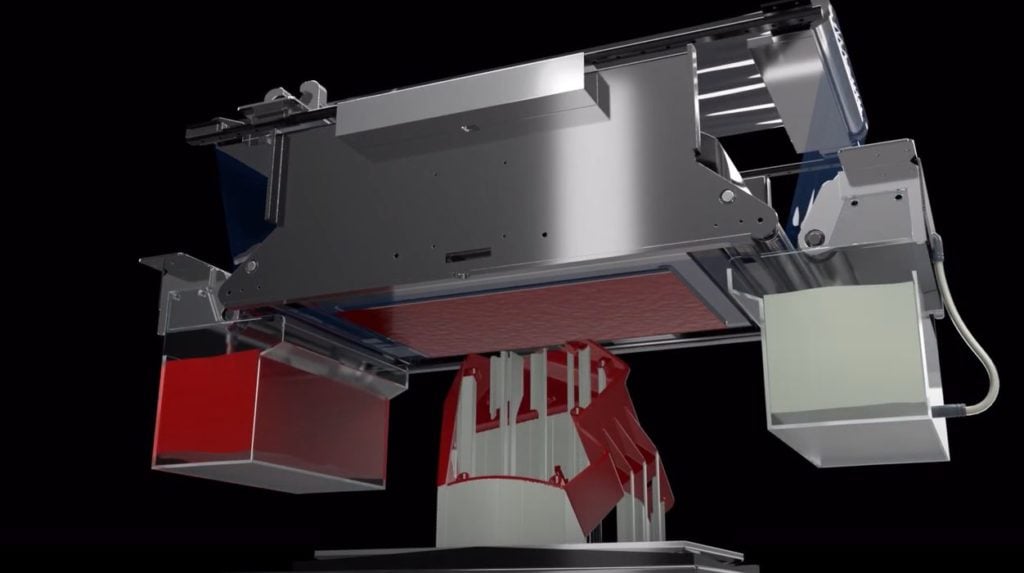

- A transparent film is passed through resin, causing a thin layer of the resin to stick to the bottom of the film

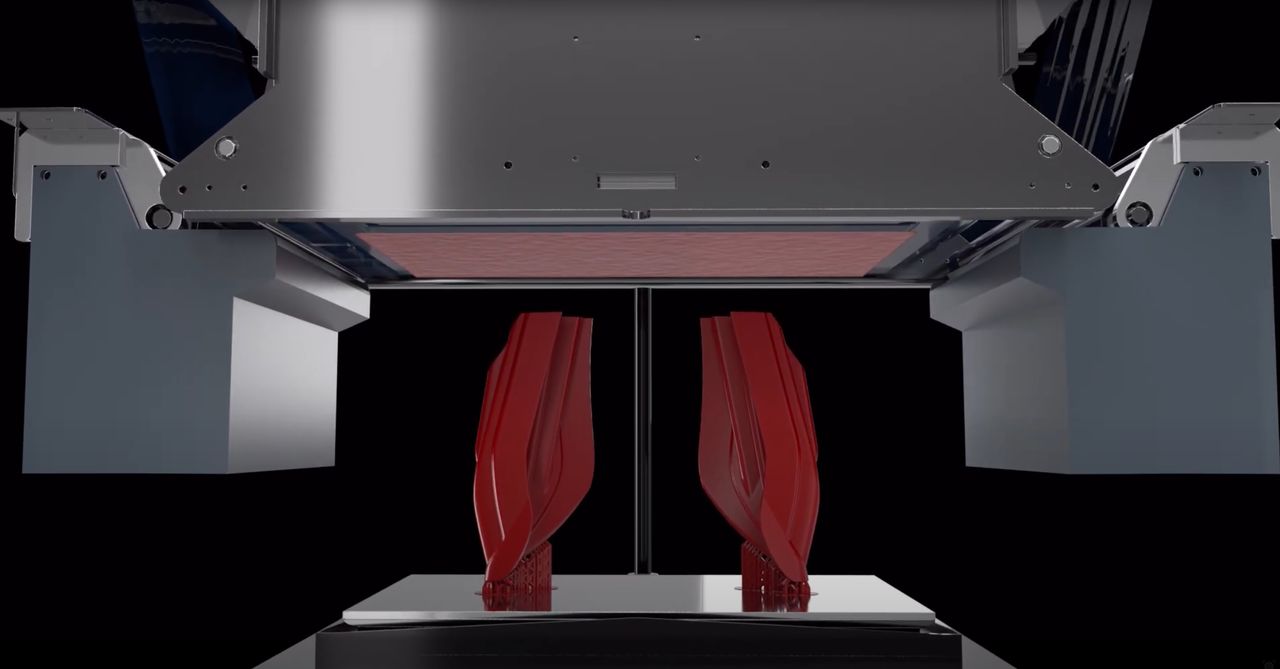

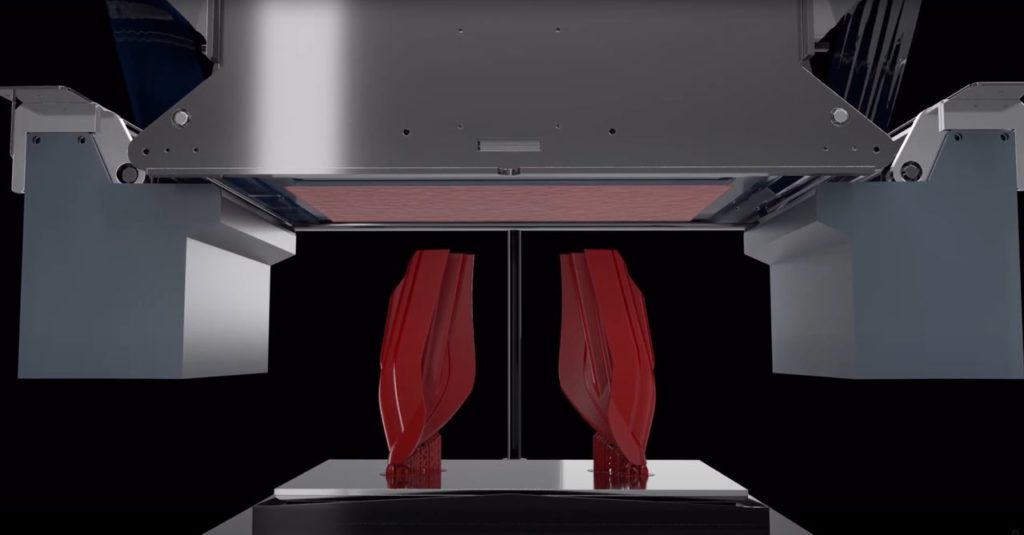

- The film is shifted into the build chamber and tensioned to be perfectly flat, still holding the wet resin on the bottom

- The build plate moves upward to come in contact with the film. For further layers, only the solid portions of the object come in contact with the film

- From above a LED/LCD panel UV light source selectively illuminates the transparent film, solidifying portions of the resin

- The build plate lowers slightly, peeling the freshly printed layer off the film

- The film, now having only unused wet resin on it, slides back out of the build chamber where the resin is recovered and made ready for subsequent layers

The process repeats until all of the object’s layers are printed.

After printing, the print is removed from the build plate, washed and cured in the same way as conventional resin printing.

VLM Advantages

The process described above may seem reasonable, but not necessarily revolutionary. However, there are two very key advantages to the system, in addition to its reuse of resin.

The first advantage is that the resins that can be used in VLM can be up to 50X more viscous than those used in conventional resin 3D printers. Normal resin printers require the resin to flow as build plates are dipped into vats. There is no such problem in VLM.

This means that the materials can be of a much wider range than those used in other resin 3D printers. This enables VLM to overcome the typical problems of resin prints being too brittle or insufficiently strong: new materials can be used.

In fact, additives can be mixed with the photopolymers to create very strong materials. BCN3D explained that it is possible to use fibers (perhaps glass or carbon) in the resin, or highly dense polymers. These additives can dramatically strengthen the parts produced by VLM and could possibly lead to additional end-use part manufacturing possibilities.

One more thing: VLM does not heat the resin in any way to reduce viscosity. In fact the process REQUIRES the viscosity to properly stick to the transparent film. The room temperature printing process ensures the integrity of the resin material.

VLM Multimaterials

VLM also offers the possibility of multimaterial resin 3D printing, something that has been only a dream for 3D printer operators who can today use machines with only a single material per job.

How does VLM achieve this? It’s actually pretty straightforward: they use a second film mechanism and material repository on the other side of the build chamber. This is shown in their short video:

Apparently the VLM process also involves a mysterious method of cleaning the resin between layers to ensure there is absolutely no contamination between the two films and resin storage areas.

The implication here is that one material could be support material. By using a different material it is theoretically possible then to use soluble supports on a resin 3D print. This is a revolutionary step as support structures are a critical feature of every resin print, yet they are also incredibly difficult to remove at times. VLM could dramatically speed up the entire resin production lifecycle because of this.

VLM Questions

One question I have about VLM is its throughput. During a discussion BCN3D, little was said about VLM’s speed and potential throughput.

Throughput is the number of units that can be produced per time period. This can be affected by the build volume: more parts per job equals more throughput.

The question then is, could VLM be scaled up? It turns out yes and no. Basically VLM uses a standard monochrome LCD panel as its light engine. This means that VLM will be limited by the size and availability of commercial LCD panels and their corresponding resolutions. So for now it would seem that the build volume of a VLM machine would be similar to today’s resin 3D printers.

Although not mentioned by BCN3D, it might be possible through the use of sophisticated lens systems to use multiple LCD panels on some future version of VLM.

Another driver for throughput is layer time. In normal resin 3D printers layer time is dominated by the motions of the build platform and the peeling process. Some advanced resin systems use sophisticated approaches to eliminated peeling, and thus dramatically speed up their layer times. This does not appear to be the case for VLM, and I expect the layer times to be similar to conventional resin 3D printers.

Based on the limited build volume from LCD panels and the time required to peel and also the delay in shifting films around, the layer times of VLM are likely not spectacular, and throughput is something we will have to see.

VLM Product Strategy

VLM is a 3D printing process, not a purchasable product. While BCN3D has spent considerable time working on the technology and partnering with chemical provider Arkema on materials, they now say they know a great deal about VLM and how it works.

Before they can finalize VLM 3D printers for sale, they wish to gain more feedback from potential users of the technology. This is the reason for their announcement of VLM today: they are asking innovative manufacturers to contact them and potentially join their internal VLM development program. This should provide BCN3D with more than enough information to develop a proper VLM printer.

As for BCN3D itself, this is quite a switch in direction, but it makes a great deal of sense. In the FFF world there is an avalanche of competitors, with more emerging each week. By developing VLM, BCN3D has opened up an entirely new market that, at the moment, has few if any competitors.

There was a reason I put BCN3D on my list of 3D print companies to watch.

Via BCN3D