Charles R. Goulding and Preeti Sulibhavi look at how 3D print technology is woven into the growth strategy of CNH Industrial.

CNH Industrial, NV is a leading construction equipment and services company. It is a pioneer in the industry and its brand portfolio includes Case IH, New Holland Agriculture, CASE Construction Equipment, and New Holland Construction.

In 2021, CNH reported total revenues of US$33.43B and employed 71,895 people. To say it is a leader in the industry is an understatement.

CNH manufactures agricultural tractors and combines, including hay and forage equipment and specialty harvesting equipment. They are a lesser-known but formidable opponent to Caterpillar and Deere, in terms of earth moving equipment, construction equipment and other heavy machinery.

In addition, CNH had already started enabling wireless connectivity between Trimble Ag Software and Case IH Advanced Farming Systems (AFS) Connect as well as New Holland Precision Land Management (PLM) Connect telematics platforms in North America. This partnership has enabled Trimble and CNH Industrial to integrate their cloud-based software solutions to help farmers make more informed decisions with their farm data.

CNH Industrial and 3D Printing

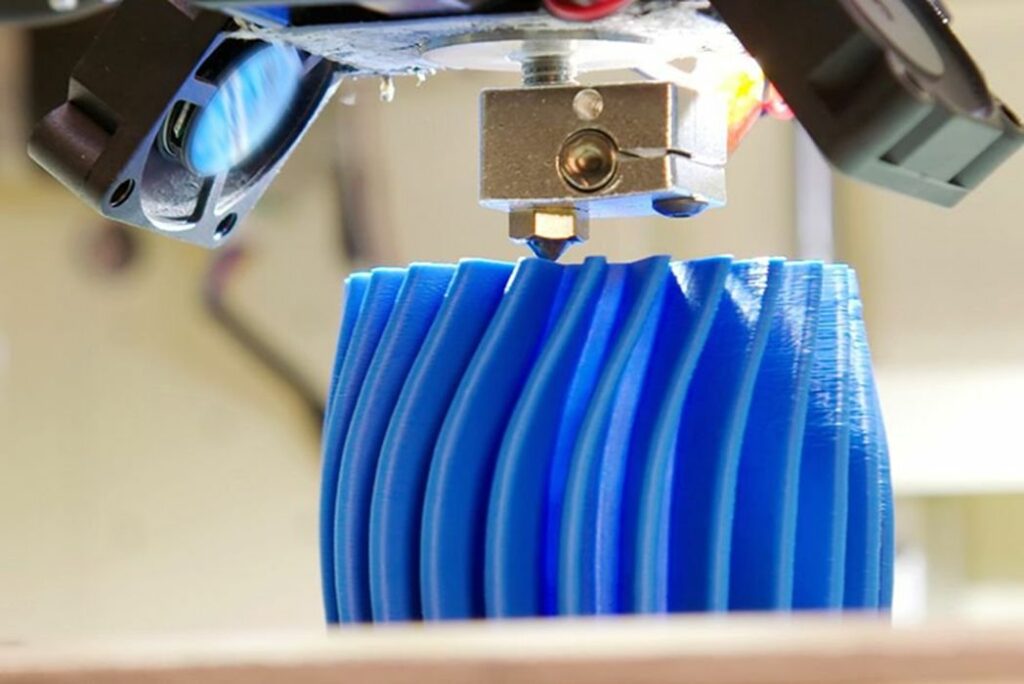

Starting in 2019, CNH began producing 3D printed spare parts for use in its farm equipment and business lines. Each of the parts went through stringent testing to ensure it met CNH’s quality standards. The components were plastic and were built from layers of the material that were designed using specialized software.

CNH appears to be committed to further investigating and integrating the potential benefits of 3D printing and additive manufacturing with the goal of producing a wide range of components in order to respond to the needs at every stage of its products’ life cycle in a timely manner.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

CNH might not be as well-known in North America, but it is steadily making a name for itself with its high-quality machinery and equipment. The fact that it has been taking 3D printing seriously is another indication of its cutting-edge strategy.