Charles Goulding and Andressa Bonafe examine a powerful combination of technologies to advance cancer treatments.

In May 2022, Adaptiiv announced a groundbreaking collaboration with HP and Varian to enhance personalization in radiation oncology. The elements bringing together this innovative trio? The fight against cancer and 3D printing.

According to the American Cancer Society, there were an estimated 1.9 million new cancer cases diagnosed and 609,360 cancer deaths in the United States in 2022. The burden of this disease is expected to grow considerably in the near future due to the growth and aging of the population along with the increasing prevalence of risk factors.

For many cancer patients, radiotherapy stands out as a noninvasive, effective, and safe treatment alternative. Owing to advances in technology and research, radiation treatment has greatly contributed to improving the prospects of those suffering from various types of cancer, including instances of early, locally advanced, and metastatic disease.

Experts point out, however, that the effectiveness of radiation oncology is tied to a shift from a “disease‐focused management toward a patient‐centered tailored approach”. Personalized care has proven to be among the main components for improving patient outcomes as responses to treatment vary considerably according to the individual’s unique physiology. Going beyond the definition of optimal treatment strategies, personalized care may include patient-specific medical devices. Adaptiiv, HP, and Varian aim to use 3D printing technology to enable such a degree of personalization at a large scale.

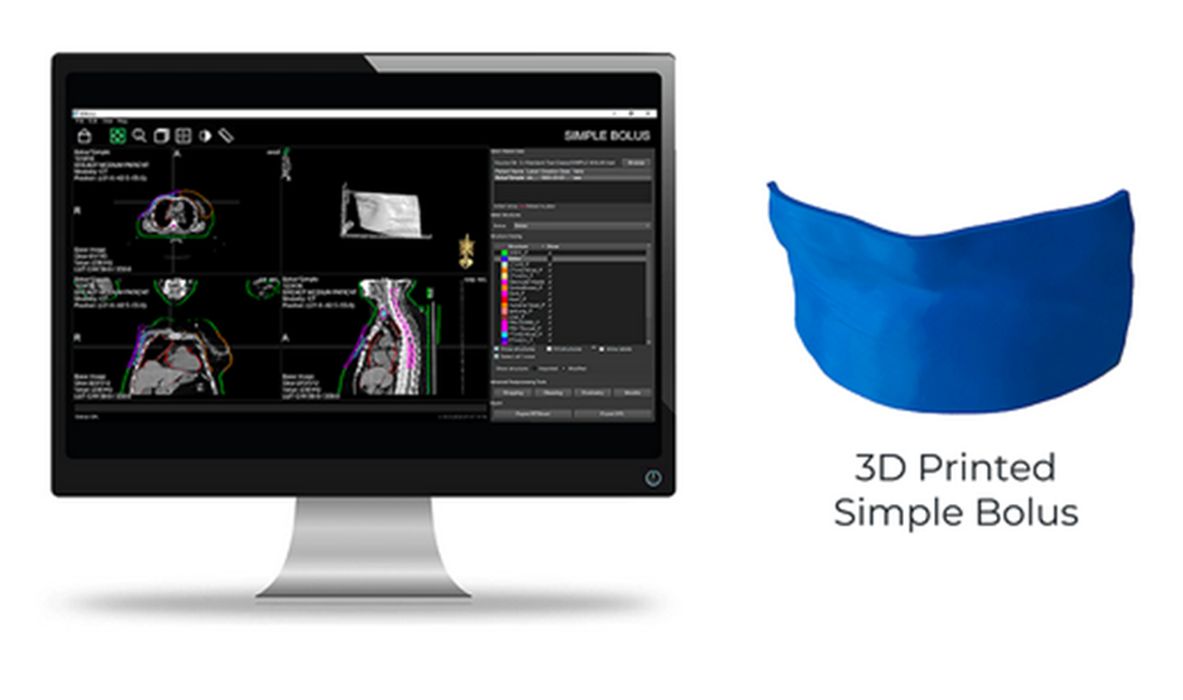

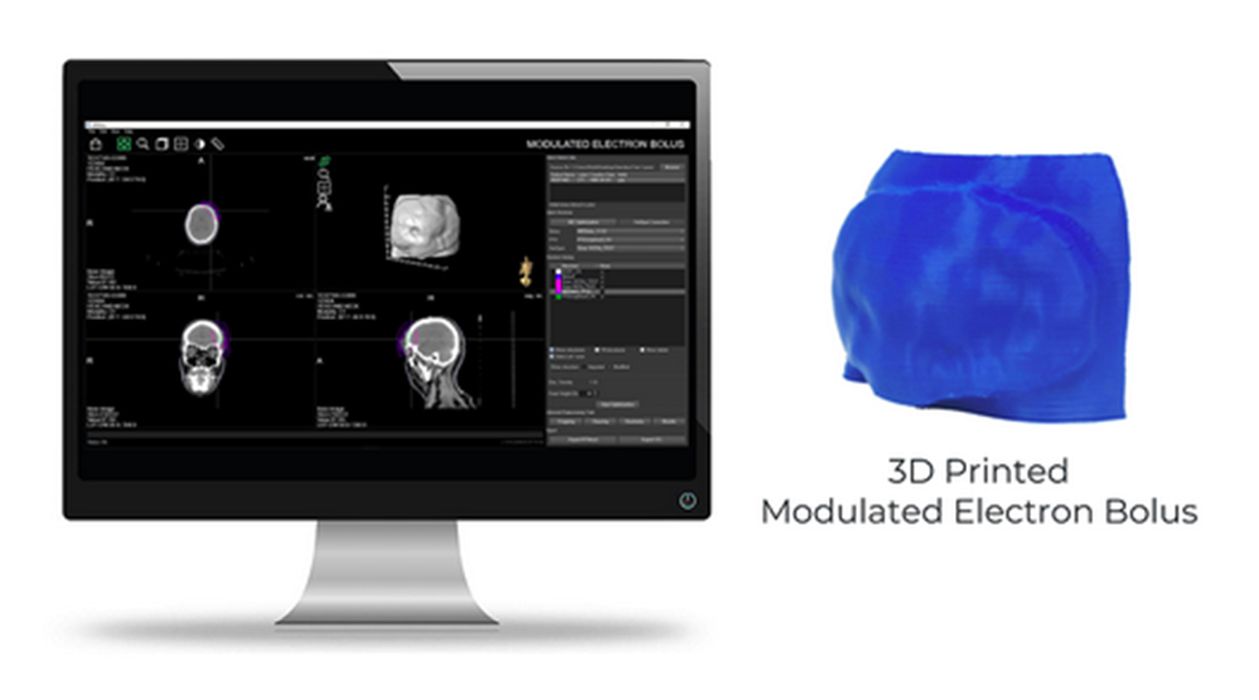

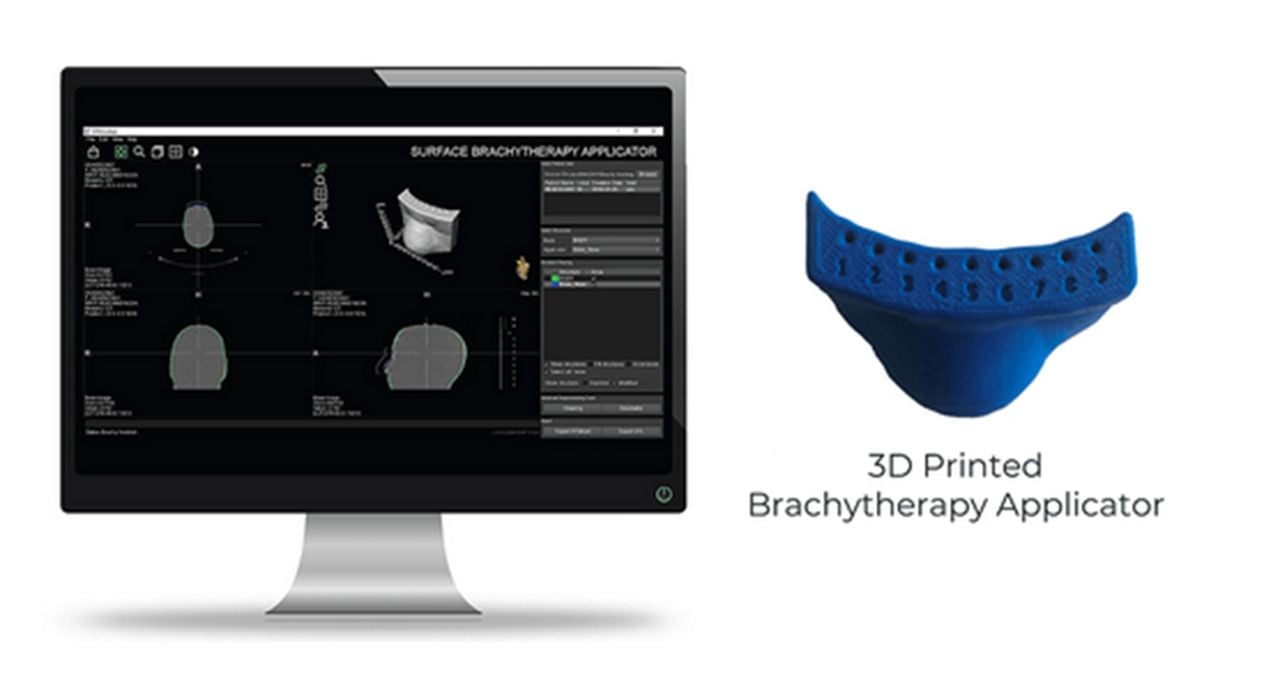

Headquartered in Canada, Adaptiiv is the creator of a unique software platform for the design of patient-specific accessories that are used in cancer treatment. Aimed at advancing the fight against cancer, the solution promises to enhance clinical precision, improve operational efficiency, and facilitate access to personalized care. The platform offers direct integration with existing radiotherapy workflow, converting patient DICOM data into a digital model that can be printed, no matter the size or complexity. Compatibility with multiple 3D printers and filament materials further facilitates application.

Adaptiiv’s current work focuses on both external beam radiation therapy (EBRT) and brachytherapy, particularly the creation of boluses, devices that are placed on top of the skin to control the dose of radiation delivered to a specific location. The software platform can be used to design and create custom 3D printed boluses for photon or electron EBRT treatments. The Simple Bolus module helps create patient-specific accessories that significantly reduce air gaps, spare healthy tissue, and provide superior dose distribution compared to traditional methods.

Similarly, the Modulated Electron Bolus (MEB) software module brings automation to the design of patient-specific and plan-specific modulated thickness bolus. These 3D printed devices help deliver modulated electron radiation therapy (MERT) dose distributions that provide superior sparing of healthy tissues and distal OARs compared to uniform thickness bolus.

For brachytherapy, Adapittiv’s HDR Surface Brachytherapy software module enables the automatic design of 3D printed applicators with customizable catheter trajectories according to the patient’s anatomy.

A Promising Partnership

By partnering up with Varian and HP, Adaptiiv’s personalized devices could reach new levels of quality and scale. HP‘s additive manufacturing expertise opens the way to the production of 3D printed medical devices at a higher pace and lower cost. The Multi Jet Fusion technology, in particular, offers enhanced control of each individual voxel, allowing for greater design flexibility and accuracy.

Varian‘s participation, in turn, promises to broaden the scope of the partnership by facilitating the introduction of personalized boluses to its clinical users. The medical equipment manufacturer is a major player in the oncology field, having invented the first linear accelerator for targeting tumors with two different types of radiation in 1972. Since then Varian has developed widely used software systems for treatment planning along with imaging devices, and advanced radiotherapy systems. The device maker was acquired by Siemens Healthineers for an astounding US$16.4B in 2021.

Activities involved in the creation of 3D printed, patient-specific medical devices are often eligible for Research and Development (R&D) Tax Credit as described below.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

The use of 3D printing to create personalized medical devices, as proposed by Adaptiiv, HP, and Varian, is key to advancing the fight against cancer. The innovative partnership combines technology, scale, and leading-edge personalization tools that promise to improve radiotherapy outcomes all over the globe.