Charles R. Goulding and Preeti Sulibhavi review recent examples of restaurants leveraging 3D printing robotics to provide automation.

We have previously written Fabbaloo stories about the synergistic opportunities from combining robots and 3D Printing. As a result of labor shortages and rising minimum wages, investment advisors such as Cowan, a securities firm, believe that increasing volumes of restaurant robots are reaching a tipping point.

A December 27th, 2022, Wall Street Journal (WSJ) article cited an 800-operator survey concluding that restaurant margins have declined to 13% from 21% pre-pandemic.

Most fast food and fast casual stores have already automated the nonfood support services including online and kiosk ordering, pick-up and drive-thru services and payments. With these accomplishments, the automation of the core food prep function is the next step and becomes the primary focus.

This article covers robot technology developments impacting three major food categories including hamburgers, Mexican cuisine, and salads.

Hamburgers

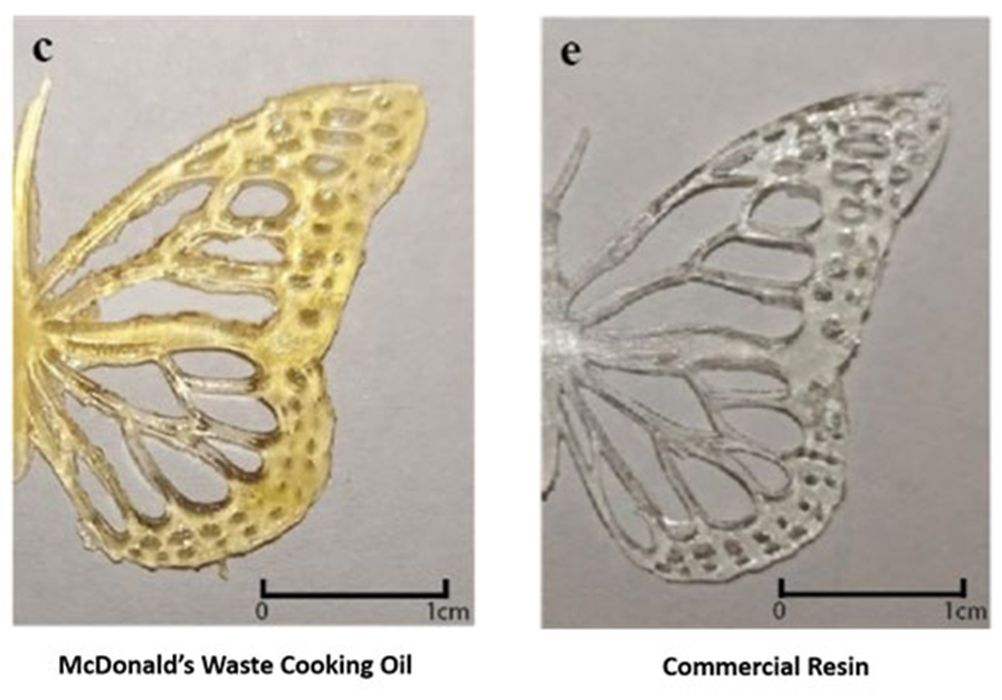

McDonalds has just announced the opening of its first automated location in Fort Worth, Texas. McDonald’s has also served as a beta site participant in a project to convert cooking oil into 3D printer resin.

A restaurant group in California has filed a petition with 1,000,000 signatures to approve a proposed California minimum wage ban that would increase the State’s 500,000 fast food workers to as much as US$22.00/hour, effective January 1, 2023.

For hamburgers, it’s not all about the meat for some people. An Israeli foodtech company, SavourEat, has provided a 3D printer to a restaurant in Herzliya, Israel so that customers can design their own veggie hamburger selecting how much fat and protein they want in their burger. Once selected the burger is printed and then cooked by a robo-cook. The whole process takes some 6 minutes from order to the plate.

The 3D printer is fed with veggie food “ink” containing chickpea, pea and potatoes derived proteins. These are combined in various ways delivering a broad variety of tastes. There is a growing market for veggie-based hamburgers (alternative protein startups harvested some US$3B in funding last year in the US) and a growing segment of restaurant goers are interested in a diet that is strongly based on vegetables without forfeiting the meat completely.

Mexican

We have covered tacos and 3D printing in a previous Fabbaloo article. But since then, Mexican cuisine seems to be expanding into even more product customized categories including tortillas, empanadas, fajitas, and so on. Some of the components of these food items can be created with the help of 3D printers. Most of these items could use accessories and appliances that can be 3D printed as well.

Bear Robotics is helping Mexican restaurants like Rogers Abuelo’s restaurant to create a smarter working environment for servers by taking on some routine and physical tasks. The robot is called “Servi” and it automates repetitive tasks such as running food and drinks to guests and it helps servers bus tables and return dishes for washing. This reduces the physical demands on servers leaving them free to provide more hospitable customer service.

Salads

Salads are a common item, especially among dieters. And with the new year on us, we think that this food category should not be overlooked. In fact, a little over a year ago there was a big acquisition by Sweetgreen for robotics startup Spyce. The salad giant, Sweetgreen, went all in on automation with this acquisition of Spyce. Founded in 2015, by MIT mechanical engineering students, Spyce has been serving up food at MIT dining halls as well as some automated restaurants in the surrounding Boston area. While it may take time to scale up Spyce’s robotics to meet the demands of Sweetgreen customers, this is a big deal in the automation world.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

The fast-growing restaurant robot category is benefitting from new automation technology and a supportive labor market. The 3D printing industry with a myriad of complementary product offerings including numerous product creation technologies can join in and create a multiplier effect.