Could PLA be used for 3D printed prosthetics?

A new research paper explores this possibility through a series of extensive mechanical tests.

PLA is a well-known 3D print material, and that’s because it is very easy to 3D print. It doesn’t warp as much as ABS, the “original” desktop 3D printing material. As a result it became extremely popular and continues in that spot to this day.

That said, PLA is not really considered a proper engineering material, as it has two deficiencies. First, it is quite brittle and has a tendency to snap if impacted. Second, it has a rather low glass transition temperature: ~60C. While that low temperature makes it easier to print, the objects can’t be used in environments with temperatures exceeding 50C without risk of collapse.

Because of those deficiencies, PLA is generally not used for “serious” applications. Makers tend to use PETG, Nylon, or other “engineering” materials for projects requiring mechanical stresses.

One “serious” application is prosthetics, specifically the joints in lower-limb prosthetics. Legs undergo all kinds of stress everyday and the same is true for lower-limb prosthetics.

If you asked me today if I would use PLA to make a prosthetic joint from PLA that would support a person, I would strongly suggest using another material.

However, the new research seems to indicate that PLA could indeed be used for this serious application. In a paper entitled, “Numerical Analysis of a Transtibial Prosthesis Socket Using 3D-Printed Bio-Based PLA”, University of Maribor researchers have determined use of PLA is possible. They wrote:

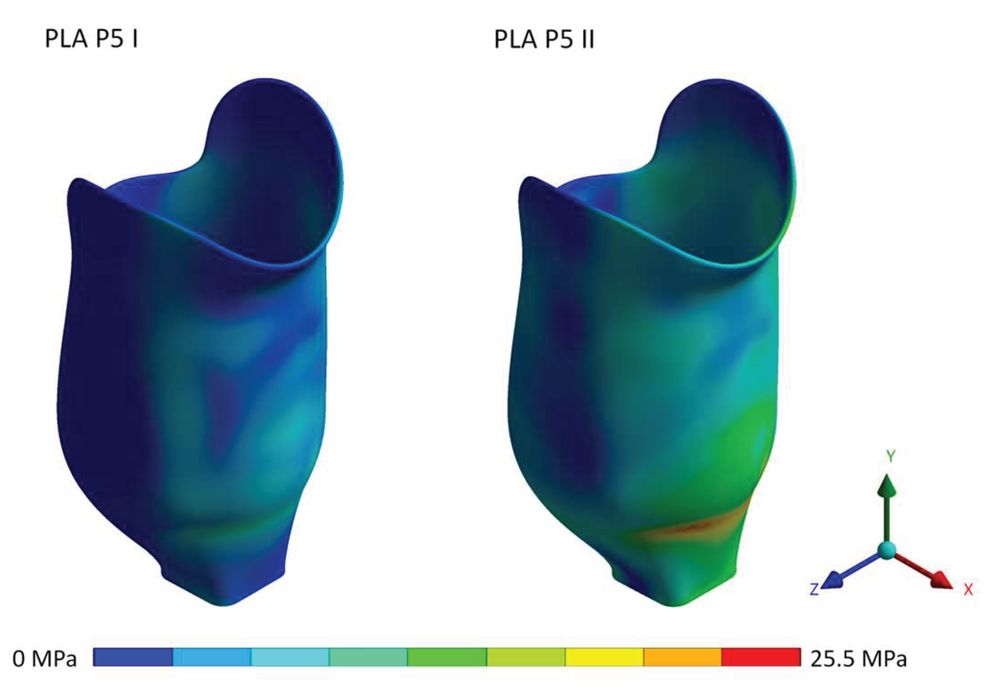

“The safety and stability of the proposed 3D-printed PLA socket were analyzed using a recently developed generic transtibial numeric model, with boundary conditions of donning and newly developed realistic gait cycle phases of a heel strike and forefoot loading according to ISO 10328. The material properties of the 3D-printed PLA were determined using uniaxial tensile and compression tests on transverse and longitudinal samples. Numerical simulations with all boundary conditions were performed for the 3D-printed PLA and traditional polystyrene check and definitive composite socket.”

What were their findings? They determined that a PLA 3D printed socket could withstand the impact of typical leg movements, push-off and heel strikes. Further, they determined that the deformation in the 3D printed socket were minimal.

They conclude:

“We have shown that an inexpensive, bio-based, and bio-degradable PLA material can be considered for manufacturing the lower-limb prosthesis, resulting in an environmentally friendly and inexpensive solution.”

Side comment: PLA is NOT biodegradable. It can be decomposed into lesser materials through industrial processes requiring tremendous heat and pressure, but it does not degrade on its own.

Will these findings turn the prosthetic industry around to using PLA for their products? I think not, as PLA is about the same price as PETG and ABS, which are both superior materials for this application. If you can 3D print the items in PLA, you can do so in other materials.

Via MDPI