A new nozzle for FFF 3D printers has been announced by fibtip, and it seems to have all the right characteristics.

The nozzle is the point on FFF 3D printers where the rubber meets the road. Most nozzles are made from brass material, which is inexpensive and transfers heat sufficient to enable 3D printing.

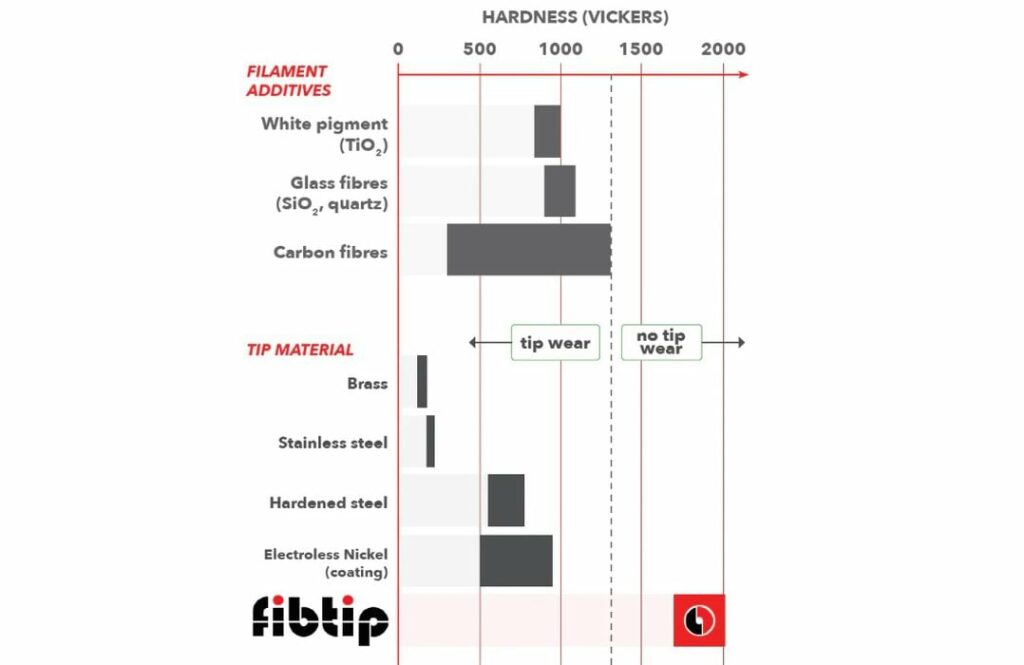

However, with the introduction of composite materials, brass nozzles have proven unsuitable in many instances. The problem is that the reinforcing materials in composite filaments, such as carbon fiber or glass, tend to harder than brass and thus gradually wear away the nozzle.

Eventually the nozzle will be so worn that the 3D print no longer extrudes the correct volume of material, and you must replace the nozzle. As a result some companies have developed “hardened” nozzles that can withstand these abrasive scenarios.

The typical hardened nozzle is made from a strong steel, but even that is subject to wear, it just happens more slowly. Other developments have used tungsten nozzles, which is a much harder metal, but is also expensive. And there are also jewel nozzles that include a synthetic coating at the tip made from sapphire material.

Nozzle technology may have taken another step forward with a development from Denmark-based fibtip, which has created another form of robust 3D printer nozzle, which they call “the greatest nozzle ever!”

At the Technical University of Denmark the founders of fibtip use a process for hardening steel using an unusual ceramic diffusion coating, originally developed by TRD Surfaces ApS. They were successful in using this technology in Diesel engines and industrial water nozzles.

This coating is three times harder than hardened steel, far greater than any of the known composite materials typically used in 3D printing.

But then they had a different thought. fibtip’s Production Manager, Alexander Hejgaard Andersen, explained:

“We then came up with the bright idea to apply our surface to 3D printing nozzles, which only proved to us that our surface has so much more to offer. In earlier applications we only took advantage of the surface’s extreme durability. We thought: ‘fine this should work well when printing in abrasive filament’, however we had some doubts about the bulk of material being tool steel. Due to tool steel not having a thermal conductivity that can rival brass or tungsten carbide. However, when we tested our nozzle and compared it to brass or tungsten nozzles we did not see a decline in thermal conductivity, but instead an increase. We later found out that this was because our surface, which is made from chromium carbide, have a thermal conductivity twice the amount of brass and even better that tungsten carbide. Even though the layer is so thin, it will still contribute very much to the thermal transfer of the nozzle.”

In other words, their coating not only provided total resistance to abrasive materials, but it also dramatically increased the heat transfer through the entire nozzle. Even though it’s made from steel, the heat transfer was tremendously greater than expected.

Another unexpected result was that the nozzle, which is entirely coated, was found to be resistant to blobbing. During print failures, very often you will find a mass of material pasted on and around the nozzle and hot end. These are usually extremely difficult to completely remove, causing black drops to fall on future prints. fibtip found they could simply lift off the blobs because they did not stick to the coated nozzle.

The ceramic coating is literally diffused into the steel, meaning that it cannot crack, even when wrenched with great force. You can even clean the nozzle with a wire brush and not damage it.

The coating will not come off at extreme temperatures, as the coating has been tested up to a whopping 650C, far higher than all FFF 3D printers.

Andersen said:

“With our nozzle you get:

Extreme durability with every filament (we even have a lifetime guarantee on every nozzle)

Anti-stick surface reducing nozzle built up, cleaning effort and clogging risk

And extraordinary thermal conductivity giving an excellent heat transfer between nozzle and filament.I know some of this sounds too good to be true, but I promise you it is not.”

At this time the company offers two 0.4mm variations of the technology: a MK8 version for Creality, Anet, BQ, MakerBot, Ultimaker and others, as well as a V6 version for Prusa, LulzBot and other E3D-compatible devices. Both are available now and cost €65 (US$69) each.

Via fibtip