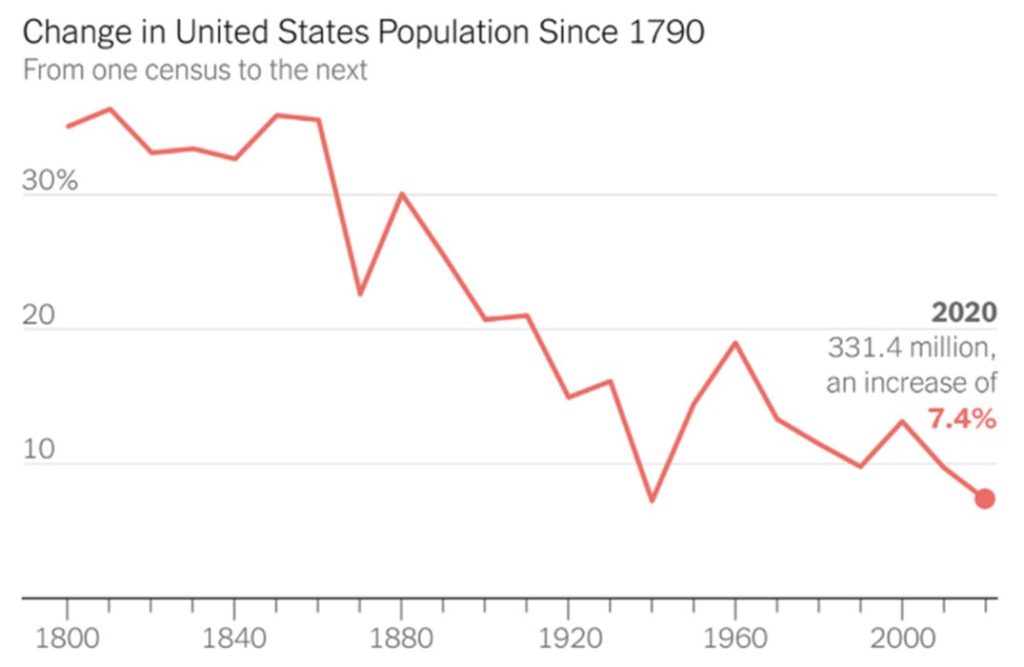

Decreasing population growth in the United States [Source: New York Times]

Charles R. Goulding and Mindy Zhu look at the relationship between country demographics and additive manufacturing futures.

In recent years countries all over the world have been experiencing a phenomenon of decreasing birthrate and population.

Some attribute it to the fact that the cost of having a child is getting more expensive as the economy grows, others attribute it to the fact that newer generations are straying away from traditional family values and choose not to have a child. This decreasing birthrate and population trend are most notable in Japan. The population of that country has been shrinking since 2007 and now has approximately 30% of their population over the age of 65. Experts have calculated that Japan’s population could drop below 100 million by 2049. This trend of decreasing populations is also happening across the United States, although for now at a slower rate than Japan.

China is currently a huge powerhouse in the global economy due to its continuously growing manufacturing market and considerable technological research. For years, China has had restrictions on population growth such as the one-child policy or two-child policy. These policies were put in place because China foresaw a future large population without sufficient resources to support the population. Recently, China has been considering lifting all population limitations by 2025. Recent economic growth has slowed and Chinese officials believe it is due to the higher percentage of seniors and lowered birth rates.

Many economists believe it is impossible to sustain growth rates with a decrease in population. Within most countries the elderly are supported by the newer generations. Since the elderly cannot work and are mostly retired, the economy is filled by the new generations that support the elderly, directly or indirectly. Since our scientific technology is also constantly advancing, humans have increased longevity, meaning that the number of seniors requiring support will continue to increase. Combined with a declining population, the number of people joining the workforce also decreases, leading to lower economic growth rates. Due to this countries experiencing a decreasing birthrate have been looking at other options to fill the workplace human gap.

One solution that is currently being examined is the use of more robots in the workplace, allowing for more automation and in turn fewer humans needed to keep a company operating. We are seeing more and more robots being used in many different industries such as manufacturing, warehouses, food, maintenance, and cleaning. Studies show that robots could take over 20 million jobs by 2030, and that number could increase even more after 2030. To find less expensive and more effective ways to build robots, researchers have been looking at 3D printed robots. Intel Labs developed an open-source 3D printed robot that could possibly be built for less than $50. 3D Printed robots provide a less expensive, more affordable option to build robots. With an affordable robot building option, the goal of replacing most of the workforce with robots is very attainable.

Another solution that many countries have been examining is the use of more 3D Printing in manufacturing and other industries in general. Japan has traditionally not utilized additive manufacturing in manufacturing except for research purposes, but as their workforce declines, additive manufacturing allows for an easy solution. Japan’s additive manufacturing and 3D printing market is expected to exponentially grow. Back in 2017, Japan invested about 30.8 billion yen (US$291.1M) into 3D printing and additive manufacturing. This trend could also be seen in the United States and other countries. The 3D printing market size is estimated to reach US$62.79B by 2028 and continue to grow. As the birth rate and population continue to decrease globally, additive manufacturing could aid and replace traditional manufacturing workforce.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

The decrease in population has led to unique solutions to replace the workforce and keep economies running. Some of the solutions lead to an increase in use of 3D printing, whether to replace the manufacturing process entirely or in part, or provide affordable options to automate workforces. Trends have shown that 3D printing and robots are constantly being introduced into the global market. In the future, we may see 3D printing and additive manufacturing solve problems we never would expect.