Let’s learn all about FEP.

FEP, or “Fluorinated Ethylene Propylene,” is a vital component in most desktop resin 3D printers. It refers to the polymer sheet located at the bottom of the resin tank.

While the actual chemistry of “FEP” might not always be precisely the chemical FEP, the term is commonly used to describe this transparent sheet that allows light to pass through and cure the print.

The Role of FEP in Resin 3D Printing

For those new to resin 3D printing, understanding the role of FEP is essential. This component is typically hidden from view, submerged underneath the resin, and is one of the most frequently failing components of a desktop resin 3D printer.

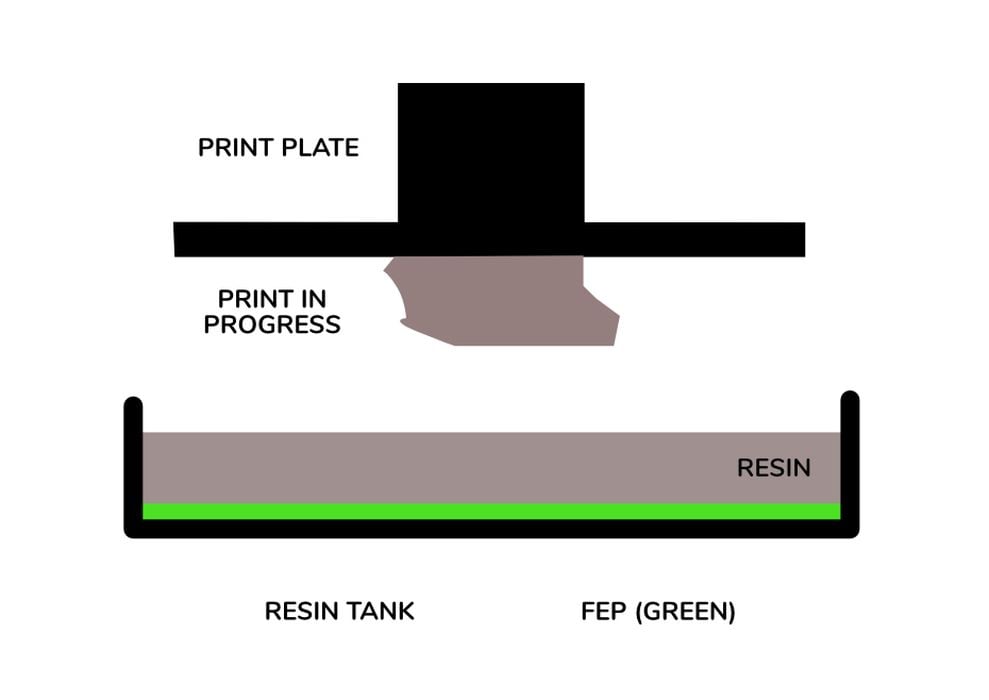

At top you can see a side-view diagram of the basic components. Here’s an overview of how FEP works in a resin 3D printer:

- The tank,in black, holds the liquid photopolymer resin.

- The FEP sheet, in green, lies at the bottom of the tank.

- A light source underneath the resin tank selectively cures each layer of the resin.

- The print plate, attached to the ongoing print, repeatedly lowers to the FEP for curing of each layer.

Resin Flow and FEP Distortion

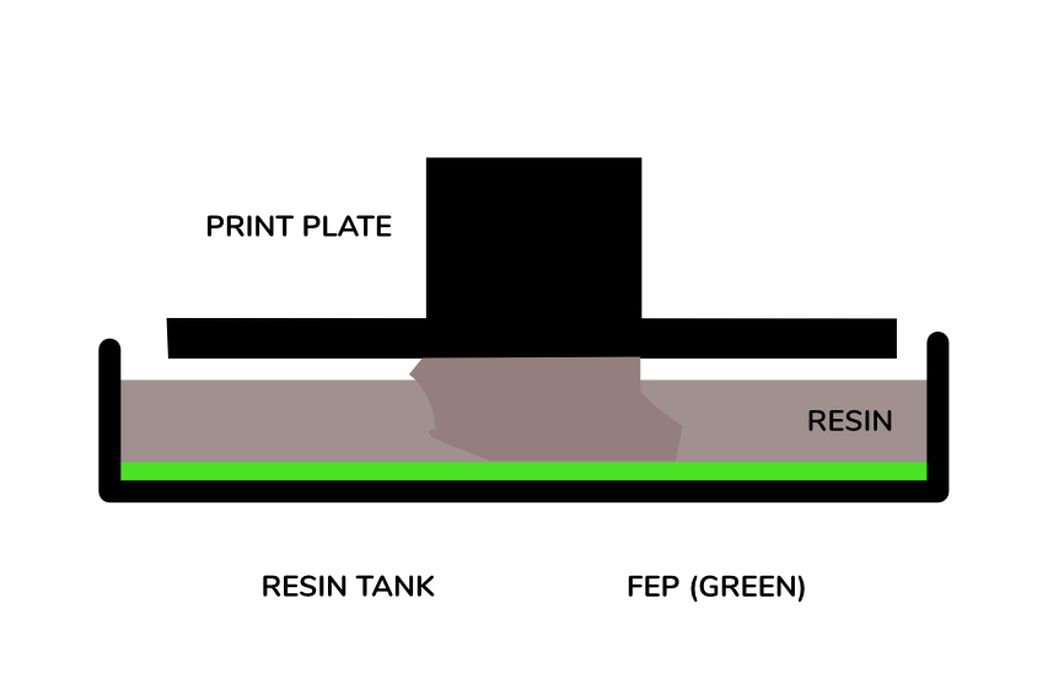

The print plate is positioned exactly one layer distance from the FEP, allowing resin in between to cure. After each layer is printed, the print plate is raised a “lift” amount to enable resin flow into the gap.

This is where it gets interesting. Wide prints or those with restricted pathways for resin flow require a greater lift distance or an increased lift delay time. If these adjustments are not made, there is a risk of attempting to cure a layer without enough resin in place.

FEP Distortion and Print Release

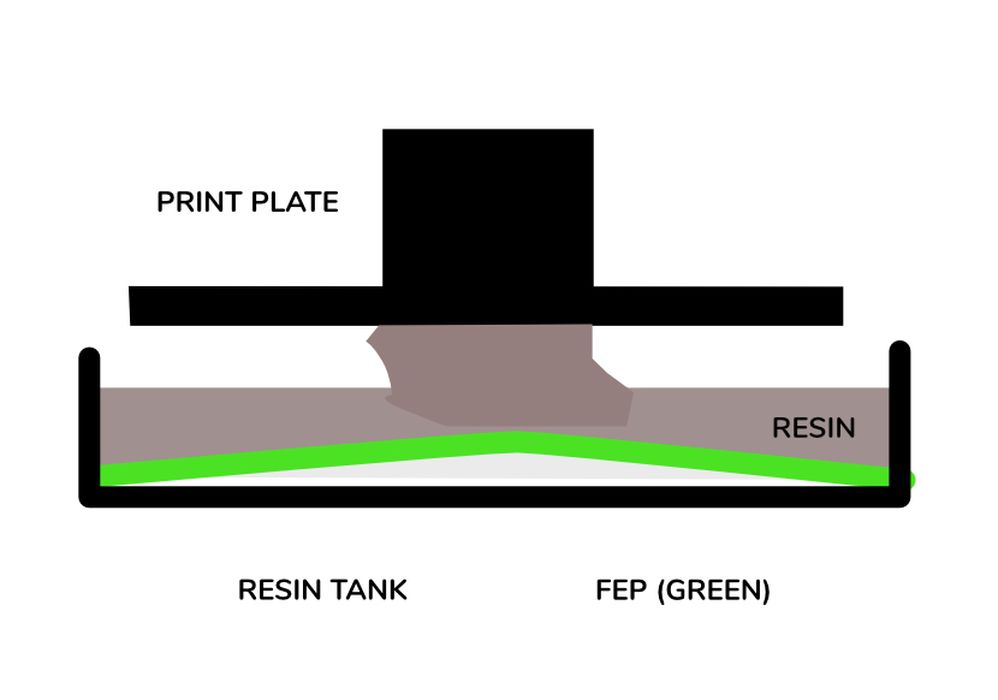

The cured resin adheres to the ongoing print, as you might expect, but it also sticks to the FEP! The print must literally be peeled off the FEP on each layer.

The force required to pull a print layer off a perfectly flat unmovable plane is far too much due to fluid suction effects, so another approach is required.

In practice, the FEP bows upwards, allowing the print layer to gradually peel off, much like adhesive tape being pulled off a surface.

Signs of proper functioning include the resin level in the tank dropping slightly as the last bit of the print releases from the FEP and an audible “pop” when that happens.

If you are printing something very wide it’s probable you need to increase the lift height again. Imagine if you didn’t pull the print far enough to break loose — it’s not the height of the layer that matters, it’s the height of the bow. Lift height is very important.

Let’s get back to the flow problem above. As you can now see, the flow problem is exaggerated by the FEP distortion: the resin has even less time to flow into the fresh layer, suggesting that the lift height must be raised even more.

Common FEP Issues and Solutions

Normally when all your settings are correct, your resin 3D printer will be sloshing through layers, popping off each one. But sometimes there are problems.

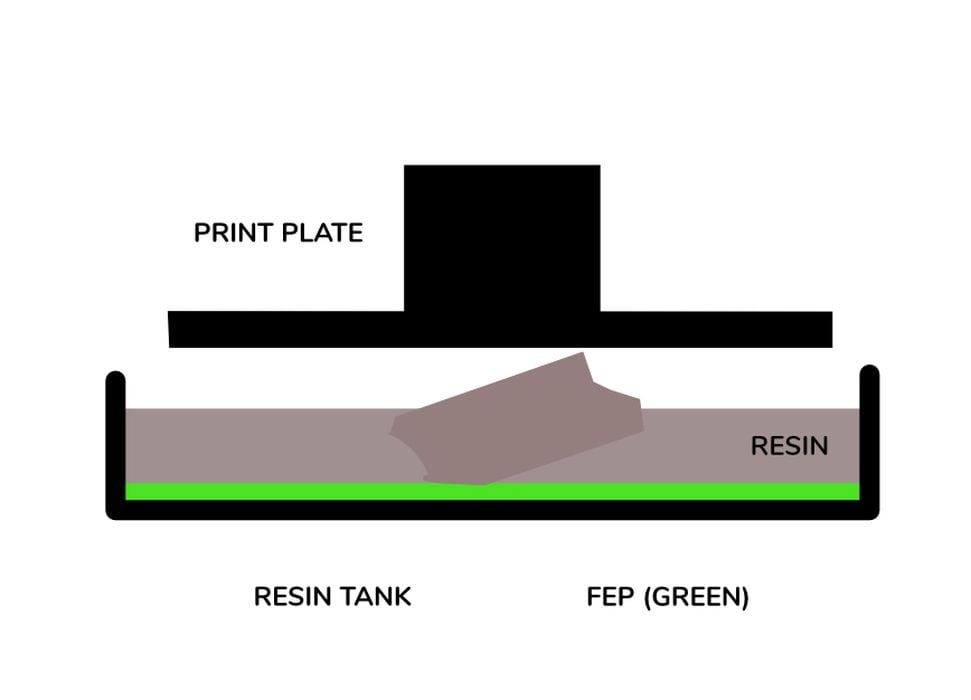

FEP problems typically arise when the print or portions of the print fail to hold on to the build plate, causing a lump of solid material to press into the delicate FEP plate and puncture it. Some reasons I’ve encountered for prints falling off the plate include:

Insufficient initial layer exposure time: the print should be exposed much longer on the first few layers to ensure it has a good hold of the metal plate.

Insufficient normal layer exposure time: if you’re not curing enough, then there is less solid material to hold up portions of the print, and they may fall off if they weigh more than their supporting structure can hold.

Bad support design: if you have poorly organized your support structures, it’s highly likely something will fall away during the print, possibly causing a FEP failure.

These issues can be addressed by carefully calibrating the resin and printing small calibration objects to fine-tune exposure times. A useful calibration tool is the Cones of Calibration from TableFlip Foundry.

Also, adding more supports than initially anticipated can help, especially for the lowest parts of the print that must support the entire structure.

Conclusion

FEP is a critical component of desktop resin 3D printers, and taking steps to ensure its proper functioning is essential.

Your FEP will thank you.