DiveDesign and Bionic Pets utilize nTopology to design end-use 3D printed parts for applications that don’t require mass manufacturing and instead would benefit from smaller-scale productions.

The Advancement

Prosthetics in general have long been an area of interest for 3D printing enthusiasts. We’ve written a couple articles here at Fabbaloo surrounding the growing industry as well, discussing everything from the advantages of 3D printing for prosthetics and the improved fit to customization the technology can offer for even facial prosthetics. Not far from these innovations lies an arguably less known, yet important, application — that of animal prosthetics.

Just a couple years back, Sarah covered an interview with Pawsthetics — a non-profit subsidiary of the 3D Printing Store — on how they are making a difference in the animal world.

Luckily, they’re far from the only helping hands. Bionic Pets is “a leader in custom animal prosthetics for animals of all kinds, especially dogs”. Bionic Pets’ founder, Derrick Campana, has worked with all kinds of animals from birds to elephants, skilfully and meticulously crafting everything by hand.

Although this offers a unique experience for each animal, full limb replacements for dogs can take up to 15 hours to create, while being extremely challenging. With the high demand for his work, it becomes nearly impossible to help the thousands of dogs who have a front limb removal every year. The longer it takes to get a prosthesis, the faster the remaining front limb deteriorates (because of uneven weight distribution), disabling the animal of mobility (and unfortunately often causing it to be put down).

This is where Dive Design came to the rescue. By adding 3D scanning, 3D design algorithms, and 3D printing to the workflow, the process consumed less time, effort, and costs, while increasing customizability, strength, and durability. Still, all was far from perfect. The feet were still being assembled the old fashioned way, using bent plastic and rubber — meaning they still took too much time to make and were not very durable.

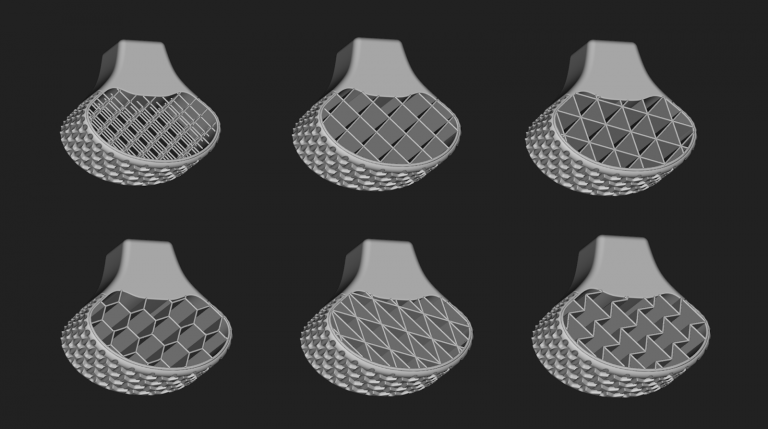

Dive Design had used nTopology to provide a rock-climbing amputee with feet. The research, knowledge, and lattice tests conducted for this prior project were quickly transferred to their new endeavor to generate prosthetic feet for the dogs, while using the same toolkits and workflows used for the remaining parts of the prosthesis. They also made a quick material swap to TPC (a type of TPE) which drastically improved energy return.

The speed and versatility of FFF 3D printing paired well with the iterative power and easily reusable workflows in the nTop platform to allow for the rapid design, testing, and shipping of products that could have taken months via the original process. Bionic Pets and Dive Design will “soon be able to tailor the foot design to the specific needs of each dog, just as the vests are”.

What Does This Mean?

I think that the most important lesson to learn is that all innovations have a farther scope than their straightforward implication. As done in this case, knowledge of pet prostheses can be shared with other companies to further the extent to which the research can change lives. Considering that some of the ideas were transferred from a project targeting a human prosthesis recipient, the research that these companies have done has an undeniable impact on medical research for humans as well. It breaks the association between customization, quality, and sky-high costs to provide customer satisfaction for people of various socioeconomic backgrounds.

Another thing that needs to be recognized is that over time, the role that animals have had in society has been continually changing. Once, they were considered to be more of a burden. Slowly, they became tolerable, but still dispensable. Today, in most households, a pet is just as much a member of the family as a human is. As someone who has always wanted a pet, I have seen how much it impacts a family when they have to put down an animal that has become one of their members. It’s great to see that someday, those decisions won’t have to be made (to the same extent).

Via nTopology