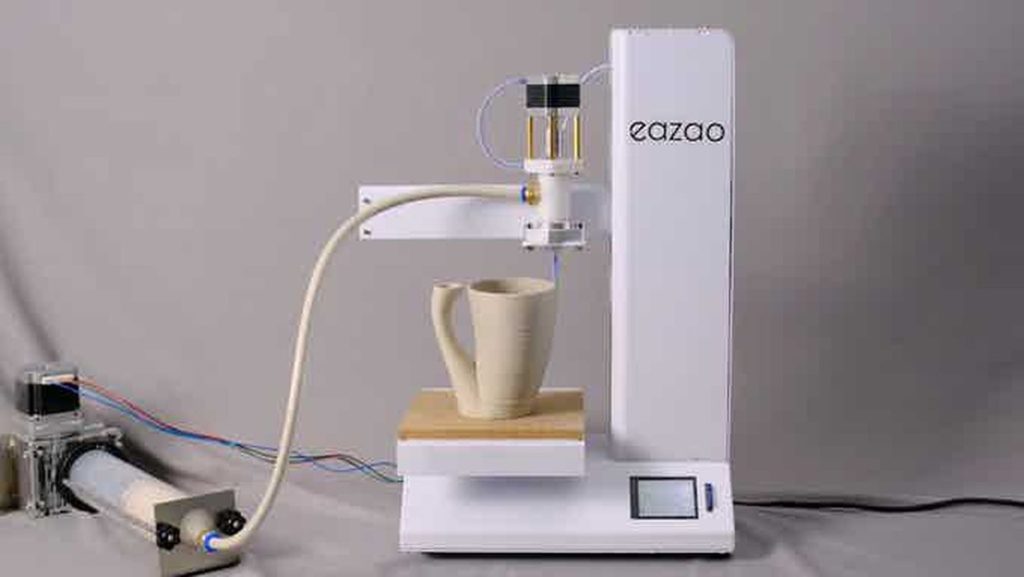

A desktop 3D printer could allow easy ceramic 3D printing at home.

Ceramic 3D printing is not a new thing; I’ve been seeing it for years, but it typically comes in two forms:

- A large, very expensive industrial device

- A DIY setup requiring considerable effort and a high-temperature kiln

Ceramic prints are incredibly useful because they have several important attributes:

- They have extreme heat resistance

- They are electrically non-conductive

- They can be made foodsafe with appropriate glazing

Most ceramic 3D printers use the following process:

- A syringe-like extruder deposits a thick line of material on the print bed

- Sloppy clay-like material is pushed along the extrusion path

- An air compressor powers the material push

- An external kiln is used to fire the print when complete

Many people would not want an air compressor running in their home, as they can be extremely noisy. This is particularly an issue for longer 3D prints taking hours or days.

For DIY operators the biggest issue is the lack of a kiln. The kiln heats the clay material to rigid form, and is a critical part of the process. The kiln can also be used to glaze a material, which makes the print much more resilient to the environment.

Kilns are by definition high temperature devices that would normally appear only in a proper workshop, and be operated very carefully to avoid the chance of a fire.

As a result of these challenges, very few ceramic 3D printers are found in homes. However, that could change with the introduction of a new ceramic 3D printer, the Eazao Zero, that provides a interesting solutions for the two main challenges.

First, they’ve done away with the need for an air compressor. Instead they have a piston system that pushes the material with great force through the extrusion tube to the nozzle. This eliminates the noise problem, and also the requirement for an external air compressor. However, the material has to be of a certain wetness to be successfully pushed with this system. You can see how to properly prepare clay for use in the Eazao Zero in this video:

The second problem, the need for a high-temperature kiln, is solve quite ingeniously. Eazao offers an “oven” that is placed inside a standard microwave oven. The material of this oven absorbs microwaves and heats up to very high temperatures. Inside can be placed a fresh ceramic 3D print, or one with glaze applied.

You can see how this works in their short video:

Note that the firing oven is extremely hot when removed from the microwave, and must be handled extremely carefully.

The Eazao Zero ceramic 3D printer provides a maximum build volume of 150 x 150 x 240 mm, more than enough to 3D print the most complex coffee mug you can design.

It provides a layer resolution as low as 0.4mm, but can go as high as 1.0mm. Note that ceramic extrusions are necessarily more coarse than typical polymer extrusions due to the nature of the material. The Zero’s 0.4mm is quite good in the world of ceramic 3D printing.

Eazao said the Zero can print up to 40mm per second, which seems extremely fast for ceramic extrusion. It’s likely in practice you must print slower, but still this is impressive.

Aside from the ceramic aspects, the Eazao Zero has all the standard features you’d expect to find on a desktop 3D printer, including an SD card interface and color touchscreen. The device is also fully assembled when purchased.

Perhaps the most interesting aspect of the Eazao Zero is its price: only US$899. The accompanying microwave kiln accessory is priced at US$80. That price definitely brings the ability to 3D print ceramics into the affordability of many more people.

The company completed a Kickstarter campaign in which they sold 375 units at discounted prices, and continues to sell the device today.

Via Eazao (Hat tip to Benjamin)