Digital Metal announced the availability of copper material for their metal 3D printer.

The Swedish company produces the DM P2500, a metal 3D printer that uses a binder jet process. Freshly 3D printed parts are then sintered to finalize them into pure, solid metal.

The company has had the device on the market for several years, and has gradually been adding new materials to their portfolio. Previously they’ve provided 316L stainless steel, titanium and other superalloys. Now they’ve added copper.

This is an important development for a couple of reasons.

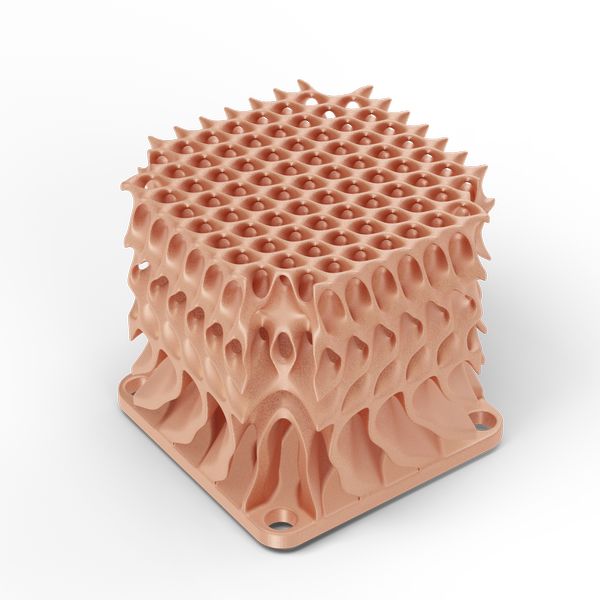

The first is that their equipment is quite unique in the metal 3D printing space, as they are able to precisely 3D print metal objects with extraordinary resolution. We’ve written about this previously but you need only look at this image to see their capability. By the way, these prints have not had any post-processing.

Digital Metal’s applications to date have included a variety of niche uses, including parts for high-end wristwatches.

The second reason is the usage of copper. Copper is a strange material in 3D printing, largely because it is extremely challenging to 3D print on conventional PBF systems. Few 3D printing processes are able to handle this metal, one of which is SPEE3d’s supersonic process. However, that process is best used for producing very large objects not requiring ultra-resolution.

Copper is a kind of wonder material because it can lead into all manner of unusual 3D printed applications. Recently I described the coming importance of copper in 3D printing, but the short version is that there are a plethora of applications that could use copper in complex geometries, due to the unique thermal and electrical properties of copper. These could include antennae, thermal radiators, and similar critical components.

When you combine the utility of copper together with Digital Metal’s ability to 3D print high-resolution complex geometries, you now have a way to address all of these interesting new applications. It’s unlikely other systems can match Digital Metal’s capabilities here, particularly for small copper objects which could be the majority of these applications.

The images on this page show some examples of copper 3D prints made by Digital Metal, and it’s pretty clear how precise and complex they can be.

According to Digital Metal’s specifications, the new “DM Cu” material is 99.9% copper, with tiny amounts of a few other elements. The purity of the metal will be of great interest in some applications.

Adding copper is clearly a very important strategy for Digital Metal, as its presence in the lineup will surely generate multiple sales of their equipment, and copper materials, too. If you need to 3D print small complex objects in copper, the DM P2500 is the system for you.

Via Digital Metal