There has been an incredibly important development in the field of plastics recycling.

Microplastics are a severe and growing problem, as decades of plastics trash has broken down into microscopic particles that now pollute every part of the globe through wind and water action.

It’s very likely that every human body now includes some proportion of these plastics, and the long-term chemical affects are unknown. This is not a good situation, and solutions must be found.

The reason for all this pollution is that there just isn’t a proper technique for efficient recycling of plastic waste. Only certain materials can currently be recycled, and then require considerable technical effort to do so.

By and large, the majority of waste plastic is simply disposed in landfills or incinerated, which both release chemicals to the environment. Evidently 79% of plastics are buried, and another 12% are incinerated. That doesn’t leave much left that is recycled, showing the terrible entire plastics recycling process.

There’s also the sorting problem: recycling centers are presented with random plastic objects that can be difficult to identify. Without knowing which materials are present, it’s unclear which recycling process should be engaged.

Even worse, the recycled plastic doesn’t get you back to “zero”. The recycled products are lower value with lesser properties. It seems that current recycling processes can only loop once or twice before degrading the material.

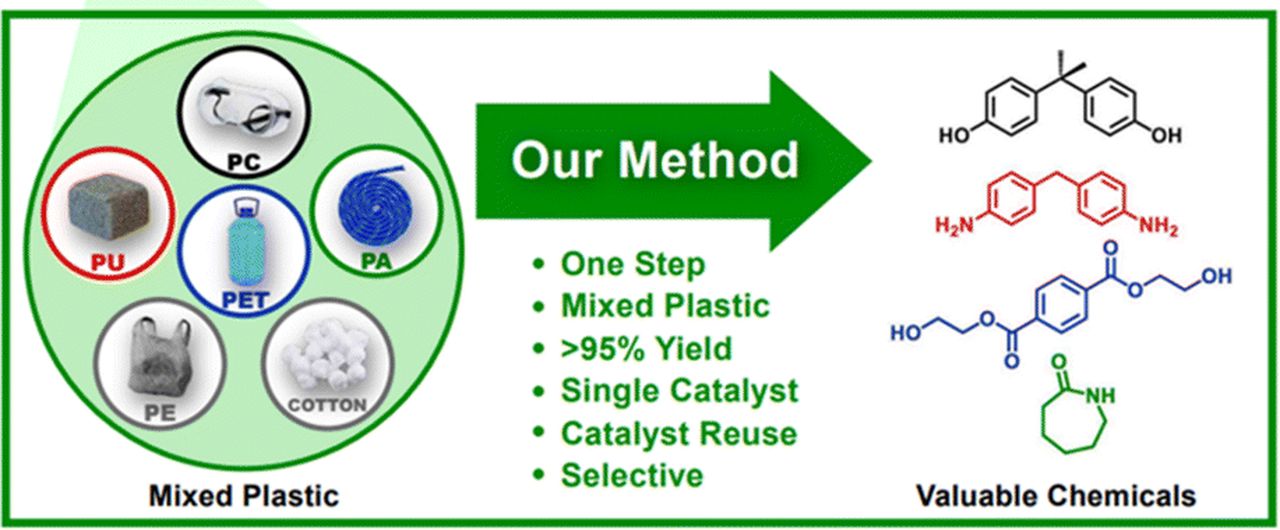

That could all change based on new research from the Oak Ridge National Laboratory. In a paper entitled, “Selective deconstruction of mixed plastics by a tailored organocatalyst” the researchers propose a new approach that is highly efficient and effective for recycling PET, PA, PC, and PU.

The researchers developed a new catalyst the enables the systematic deconstruction of multiple polymers in a unique thermal process. It seems that the catalyst acts on specific materials only when particular temperatures are reached.

Here’s how it works: a recycling depot would pour in a mixed stream of plastics into a single processing system. The catalyst would be added, and then the temperature would be raised.

At +130C PC material breaks down into basic monomers that can be removed from the system. Then, at +160C, PU material breaks down in a similar manner. PET reacts at +180C, and PA at +210C. At each temperature level, fully recyclable raw materials can be drawn from the system.

The system is said to require 95% less energy than prior recycling systems, and produces far more usable raw materials. These “zero” materials can then be used to remake new plastics directly.

One can easily imagine a recycling reactor of this type being established in major centers, where vast quantities of plastic trash can be properly recycled.

Some of that trash can be 3D prints, and finally there will be a way to safely get rid of all those plastic dragons.

Via RCS