FormFutura unveiled their new ReFill 2.0 spooling system.

The “refill” concept is gaining momentum in the 3D print world. Instead of shipping filament on a (sometimes) recyclable spool, only a coil of filament is shipped. The coil is then mounted on a self-printed reusable spool. Typically these split in half to allow installation of the filament coil.

There are two main benefits to the approach: first, the filament is less expensive because there’s no cost for the spool, and shipping costs are somewhat less. Secondly, there’s an ecological benefit as there are far fewer spools to deal with.

Interest in spool-less filament is primarily driven by the increasing number of 3D print farms, where dozens or even hundreds of machines are put to work producing parts. Keeping the cost of those prints as low as possible is partly accomplished by using low-cost refillable filament solutions.

FormFutura first introduced their ReFill system about a year ago. The well-regarded filament provider saw an “enormous success” with the initial system. Now they’ve improved the design with ReFill 2.0.

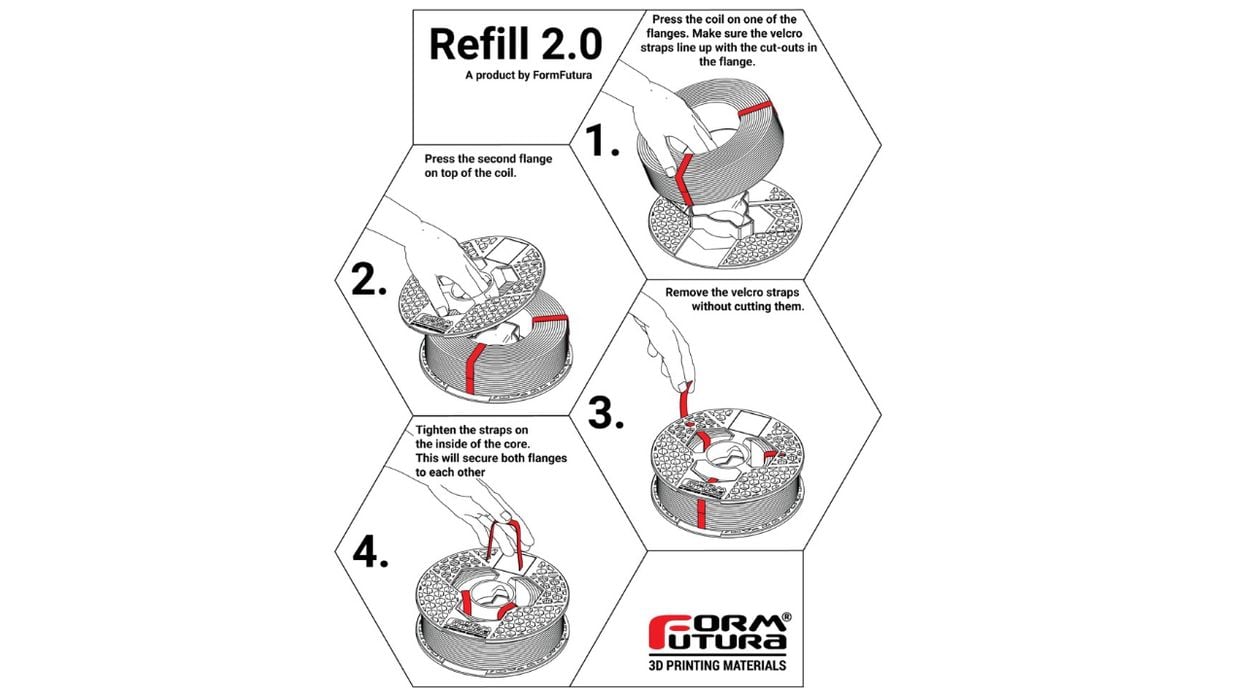

The ReFill 2.0 system is quite interesting because it combines components required for shipping with the refillable spool. Here you can see the instructions for use:

The straps hold the spool together during shipment, which is critical to avoid tangles. The spool must be mounted in a process that also avoids tangles, and this is where some alternative approaches fall down.

The straps remain attached until the coil is securely places on the half-spool. Then they are released, and wrapped around the spool halves to secure them together. The straps can then be reused as required.

It’s a pretty foolproof system for very quickly mounting a coil on a spool without risk of tangles.

By the way, tangles can be quite disastrous, particularly with TPU material where the spaghetti-like filament can almost instantly fall into an unrecoverable mess. Proper filament handling is critical, and it seems that FormFutura has a method of doing this that works well.

They explain:

“The innovative system eliminates the need for individually spooled filament and boxes. FormFutura now offers filament wounded around a cardboard core instead. Two reusable flanges will secure the filament in place. Users have the flexibility to either 3D print these flanges using the free STL files provided by FormFutura or acquire pre-printed flanges directly from the brand.

The ReFill 2.0 system sets itself apart from comparable existing solutions by utilizing Velcro straps instead of single-use ones. These reusable Velcro straps serve the dual purpose of not only securely holding the flanges together but also facilitating the interchangeability of the flanges. Users can effortlessly switch between colors or materials without the burden of finishing an entire coil. Consequently, a user might only require a single set of flanges.”

The company believes the ReFill 2.0 system will reduce their packaging waste by 80%, as well as decreasing shipping volume by up to 55%. Those are significant figures, and if widely used will make a contribution to sustainability.

FormFutura offers ReFill 2.0 coils and spools in two formats: 750g and 2000g, the latter best used for print farms.

The refillable concept has clearly been proven, and I’m wondering why many other filament providers don’t offer filament coils.

Via FormFutura