Formlabs is running a very unusual online survey.

The company began years ago by making the first reliable and inexpensive SLA 3D printers, but in recent years has been developing SLS equipment for use by professionals and manufacturers.

The company’s first SLS device, the Fuse One, has been released for a while now, after a considerably long development process. It would seem reasonable that the company is now internally developing a follow-on 3D printer.

Of course, we know nothing about what that SLS machine would be, since it hasn’t been announced. Its characteristics are probably still being finalized by Formlabs, but a survey may hint at what they’re up to.

The survey was sent out only to certain individuals by invitation, and it was one of the more unusual survey’s I’ve seen. The introduction explained how it worked:

“In the first section of this survey, we’ll ask you to assess two hypothetical SLS 3D printers side by side. In each instance, we want to know which one you’d prefer, assuming all other factors remain the same. Once you make your choice, you’ll be asked if you would choose the option you selected if no other products were available.”

There were ten “rounds” of these assessments to complete the survey.

I was a bit excited to see what Formlabs would put on offer, as I expected to see machines that might be close to what they are working on. However, that turned out to not be the case.

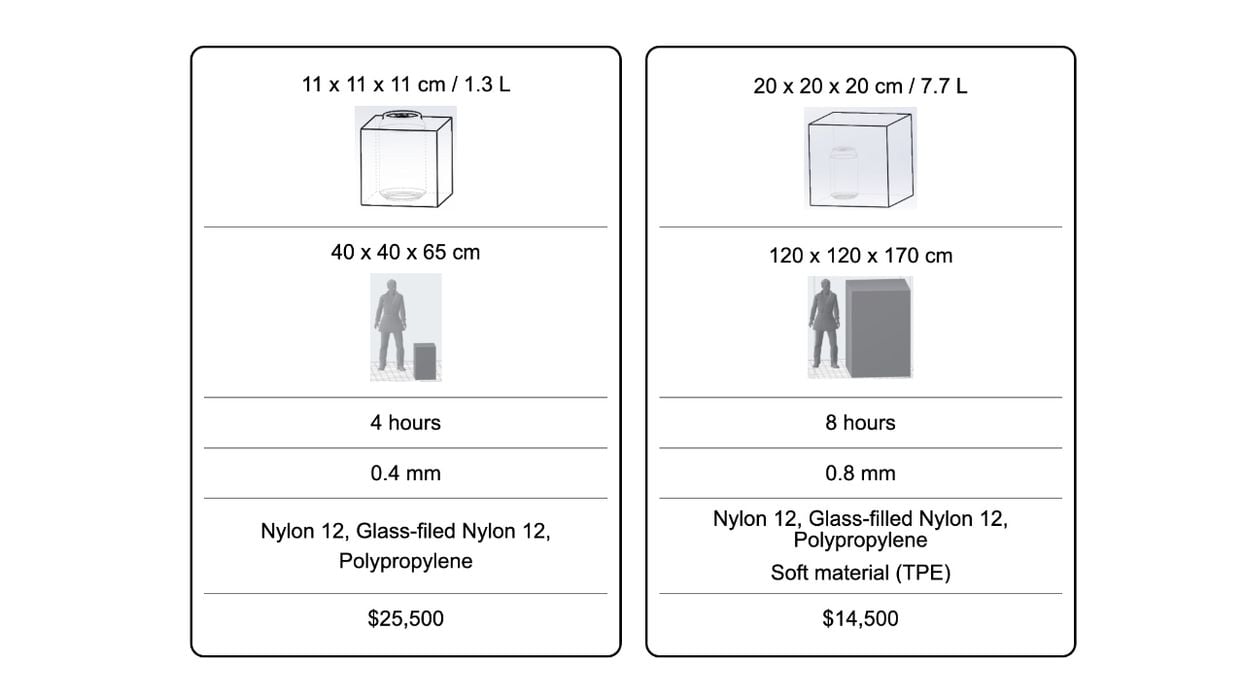

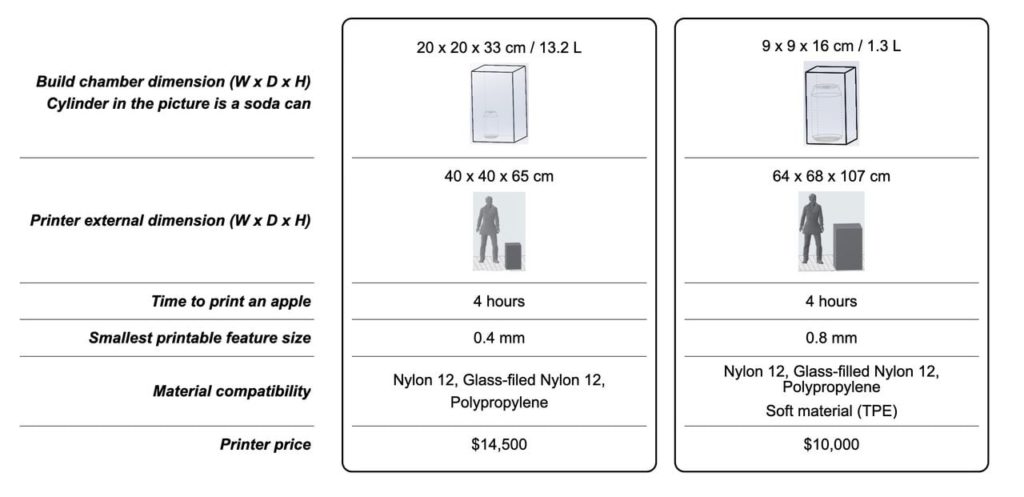

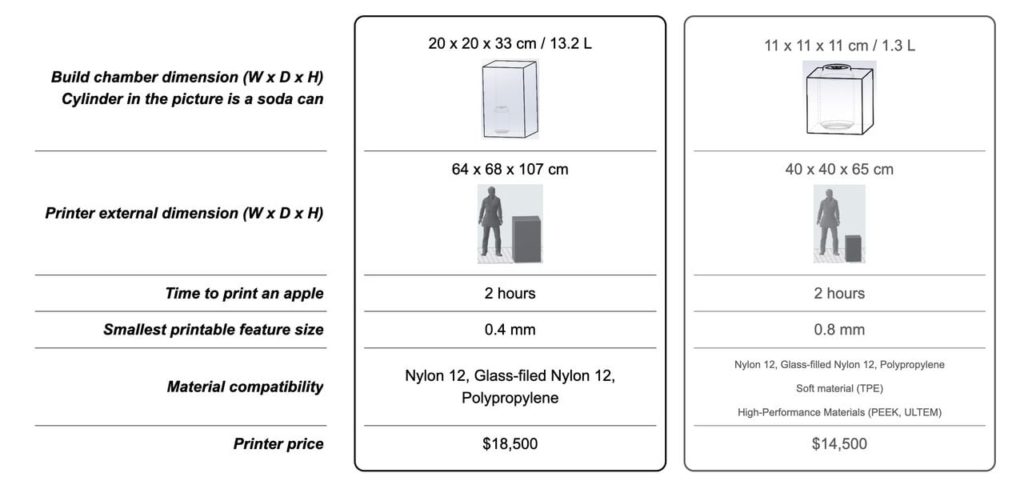

Each “round” looked something like this:

As you can see, the options were not anything like a specific product or anything close to resembling one.

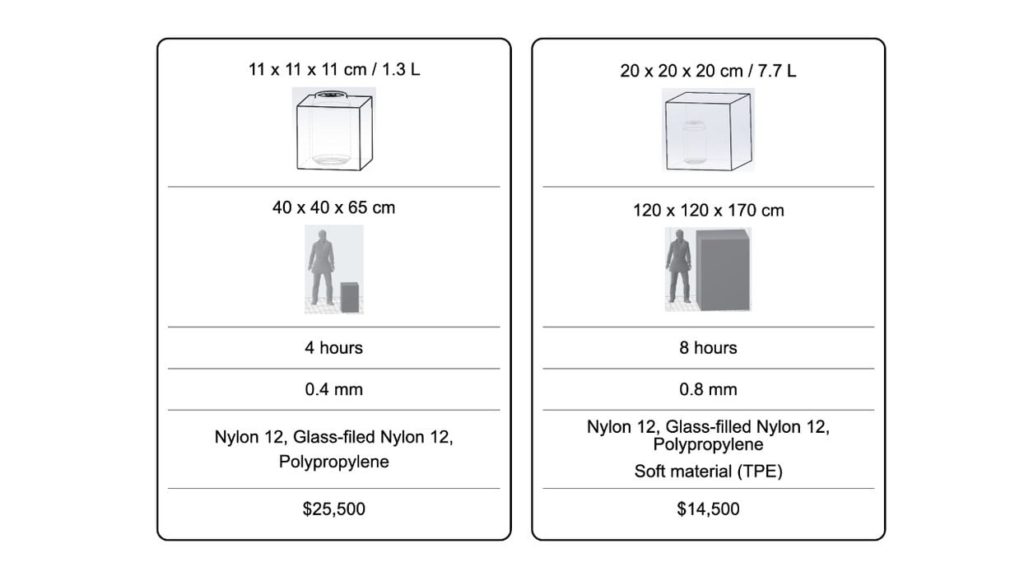

Here’s another round:

As the rounds continued, it became clear what was really going on. Formlabs is trying to gauge the importance ratio of these six factors:

- Build volume

- External size

- Print speed

- Resolution

- Materials

- Price

We’re used to picking a product from limited options and in many cases the evaluation factors are simpler: one might disqualify a product entirely. For example, a budget might be lower than the product price, or the doorways are too small to fit the machine.

But what if you’re the manufacturer of the device? What choices should you make about these factors? Which factors are truly more important to the customer? That’s what Formlabs is doing here.

It’s challenging to simply ask customers and prospects because they will often overly focus on one aspect or another: “It has to be less than $10,000”, or “Needs to print PA-12”, while not considering the implications of other factors that would make up the machine. There is no such thing as a perfect machine; there’s always something out of balance, either price, function or speed.

Each option presented had some kind of compromise: big and fast, but too expensive; or compact but slow; etc. By analyzing the responses to these rounds, Formlabs should be able to clearly see the sweet spot for a machine configuration among their respondents and do so without the inherent feature bias you’d see if asking directly.

For example, they might end up with an SLS machine like this:

- Build volume: Compact

- External size: Desktop

- Print speed: Moderate

- Resolution: Moderate

- Materials: Wide variety

- Price: Moderate

Or this:

- Build volume: Large

- External size: Fridge

- Print speed: High

- Resolution: Low

- Materials: Limited

- Price: High

If you’re the machine designer this would be critical information to be aware of when developing a new device.

I’m impressed that Formlabs would take the effort to do a survey of this type. The results will almost certainly guarantee the success of their next machine because it will fit the market.

More 3D printer companies should do this type of work before they initiate their next product development project.

Via Formlabs