Formlabs announced their fourth-generation line of 3D printers today, the Form 4 and Form 4B.

The company has come a very long way from its first 3D printer, the Form 1 back in 2013.

Formlabs CEO and co-founder Max Lobovsky explained:

“Form 4 is a huge leap not only for Formlabs and our customers, but also for the entire 3D printing world. More than a decade ago, Formlabs created the desktop SLA 3D printer category and set a new standard for accuracy, reliability, ease of use, and affordability in 3D printing. We’ve built on the strength and insights gathered from more than 130,000 printers on the market and over 300 million parts printed to deliver the Form 4, our best SLA printer ever. Its reliability and new level of speed will transform how our customers develop new products.”

There are multiple new features and concepts in the Form 4, some quite a departure from previous equipment.

The main feature of the Form 4 seems to be its far higher print speed. Formlabs explained that this is due primarily from their new Low Force Display (“LFD”) print engine. They say LFD can print at speeds up to 5X previous models, which is quite significant.

How does LFD achieve this? Formlabs explains:

“A departure from laser and galvanometer technology, Form 4 features an ultra high power backlight (16 mw/cm2), proprietary release texture, Light Processing Unit 4 (LPU 4), and dual-layer, flexible film resin tank.”

This is masked stereolithography (MSLA) technology, quite different from Formlabs’ former SLA approach. MSLA is used by almost all of the low-cost resin 3D printers on the market, while laser-based systems provided higher quality output at higher cost. It may be that Formlabs found a way to produce the same quality but with the less expensive MSLA approach — which also provides a huge print speed advantage.

Formlabs also seems to have developed a quick release method. This reduces the time required to detach the freshly printed layer from the resin tank, a process that can take up a significant amount of time during printing.

The resin tank itself, in combination with the LFD engine, is said to be far longer-lasting. Formlabs said tanks are now usable for as high as 75,000 print layers, which is quite large.

Another interesting aspect of the Form 4 is reduced operating cost. According to Formlabs the device can be as much as 40% less expensive to run:

“Delivering affordability with long-lasting resin tanks (75,000+ layers) and Light Processing Unit (1M+ layers), 33% lower resin pricing, 30% larger print volume, and 3.5 times higher throughput.”

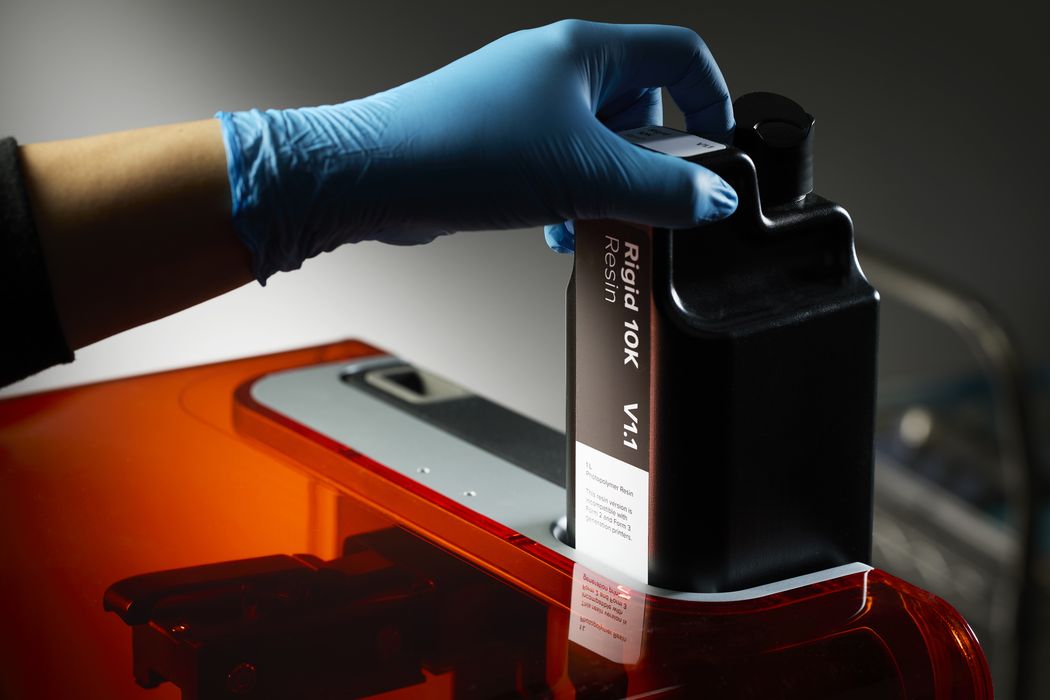

Finally, Formlabs introduced six new resins for the Form 4 and other equipment, including several that are specifically tuned for LFD printing. The Form 4 printers are also able to use more than 17 resins from the company’s extensive catalog of materials.

The Form 4 and Form 4B are available today at starting costs of US$4499 and US$6299 respectively.

Via Formlabs