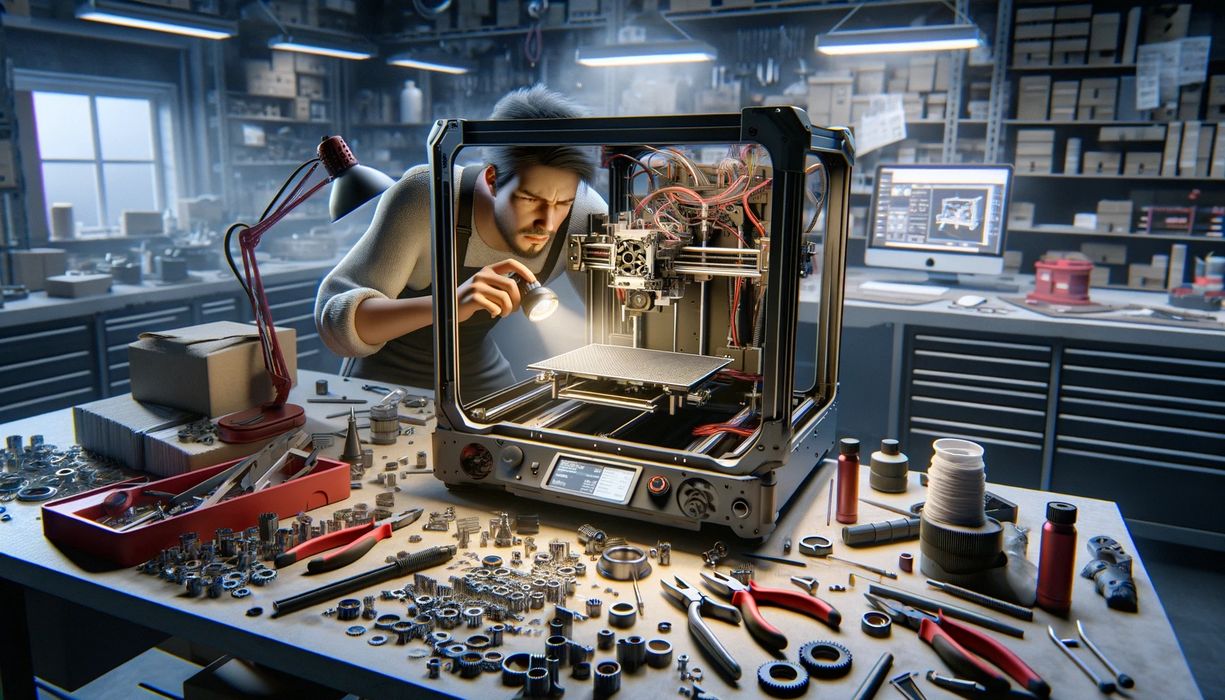

If you have a 3D printer, you will know that it does break from time to time. But how should you go about fixing it?

The easy way out is to simply call for help, and that’s what a lot of people do. But there’s always people that somehow seem to be able to fix machines on their own, sometimes even if they’ve never seen the device before.

What secret method are they using to fix these machines? Is there a process one can use to fix broken equipment?

It turns out there is in fact such a process for troubleshooting, and I’m going to give it to you now.

This process is very generic, and that’s why it can be applied to almost any machine, including your 3D printer. The key is to use a systematic approach, rather than poking around and pressing all the buttons. Here’s the steps I use, and you can too on any broken device:

Identify the Problem

What exactly is broken? What was expected to happen but did not happen? When is the problem occurring? Constantly or intermittently? Who is having the problem?

It’s really important to define what you’re trying to fix, otherwise you end up chasing other unrelated issues and making incorrect assumptions.

Define the Scope of the Issue

Which part of the machine is affected? What continues to work, and what doesn’t work? This focuses your attention on the area that requires work.

Check for Obvious Issues

A quick visual inspection often reveals the cause of the problem, or at least additional symptoms. Things to look for are anything that is not in the normal state. Consider looking at cables & connections, visible damage, debris, power, job settings, etc. Is it plugged in?

Consult Documentation

You may not be calling for help, but many devices, 3D printers included, come with user manuals with troubleshooting sections. These often list typical issues and what you can consider doing to fix them.

Another step to take is to review the operating process as described by the manufacturer: did you follow it? Did you do all the steps? Maybe the problem is you!

Perform Diagnostic Tests

Some machines have diagnostic tools that run the machine through a test sequence. This could be useful, as it would quickly identify incorrect readings. In the absence of a formal diagnostic, one can always just do a test print: does it work? Does a different print work? What is the difference between the two prints? This could point towards the problem.

It may also be possible to perform some physical tests. Is the filament being pulled strongly enough, or is it tangled? Does the MSLA light engine light up? Depending on the machine, there are a number of these tests that can be done to verify correct operation, or if not, identify the problem area.

Analyze Findings

This is perhaps the tricky part. After doing all of the above you will have some data about the problem. Look for patterns and similarities in the data. Does it happen on a certain layer? Only with big objects? Then you must be creative and come up with a hypothesis of the problem. What could be causing the problem? Ask yourself, “if this item is not working properly, would that cause all of the symptoms I’m seeing?”

Test the Hypothesis

At this point you’re ready to try to fix the problem. Based on your hypothesis, try to prove that it is correct. This almost certainly involves changing something on the machine, be it something physical or print parameters. In some cases you may need a spare part installed to observe changes, and that can delay the process. Note: always use safe work procedures when working on any machine. Ensure the power is off, hot ends cooled and be aware of sharp edges.

However, once you make the change you will find out if the problem is solved. If not, go back and make another hypothesis and repeat. Solving machine problems is often very iterative, and it will likely take several attempts to narrow down the problem.

Test the Machine

Once you’ve got the fix in place, it’s time to test the machine. This might involve re-running the job that encountered the problem, or several different jobs to exercise the new parts. It depends on the nature of the problem. You may want to monitor the device for a period of time to make sure that you truly have repaired the issue.

That about does it. This is more or less the general procedure I use when I encounter a broken device. Sometimes fixing a machine is quick, other times long. Regardless, a systematic procedure is what you need to do.