Charles Goulding Jr considers how geothermal energy might come together with growth in 3D printing.

Geothermal’s Unrealized Potential

Ten years ago, a large federal tax credit boosted some clean energy industries. Solar, in particular, thrived. For geothermal technology, by contrast, growth was steady (3-5% per year) but hardly remarkable.

One reason is pricing. As silicon costs fell, so too did costs of solar panels. At the same time, panel efficiency improved vastly, leading to even more savings at the meter.

Geothermal technology has never had an issue with efficiency; the best installations can reduce power bills by as much as 80%. The problems have always been 1) technological challenges at individual site locations and 2) often prohibitive cost.

The 3D Printing Opportunity

Geothermal projects make use of energy stored under the Earth’s surface. Often, natural or manmade reservoirs supply very hot water to heat buildings. Getting to the reservoirs — if not creating them — is a complex drilling task unique to each site.

Energy expert Dave Roberts speculates thoughtfully that the fracking boom could yield transferable knowledge and technology to geothermal site drilling. But even if new technologies can be so transferred, they may not be as cost-effective in the comparatively small-scale context of geothermal. Further, the high specificity of each geothermal project may still require additional, affordable tools and other products to justify projects in particular locations.

If cost and tool customization challenges sound like a 3D printing opportunity, new research agrees. Indeed, key phases of an installation, from reservoir characterization to field construction to reservoir operations, are all technology intensive activities.

Ready! Set! Make! Geo!

The government also sees a bright future for geothermal and 3D printing. A new $4.5m competition called the 2020 American Made Challenge attempts to cross-pollinate additive manufacturing with geothermal industry as much as possible.

According to program lead Sarah Gomach, “[o]ne exciting aspect about this prize is that we are targeting two groups and trying to bring them together…. One group is people who have experience in geothermal but limitations in tooling or components, but they also have an idea to improve it. The second group is the additive manufacturing community—a big part of this prize is bringing manufacturing advancements to the geothermal community.”

Gomach and co. oversee the competition with the help of the DOE. Ready! winners so far have included:

- An air “hot” hammer bit that will stay intact up to 600°C drastically speeding up the drilling process;

- Helical downhole heat exchanger for a closed loop system; and

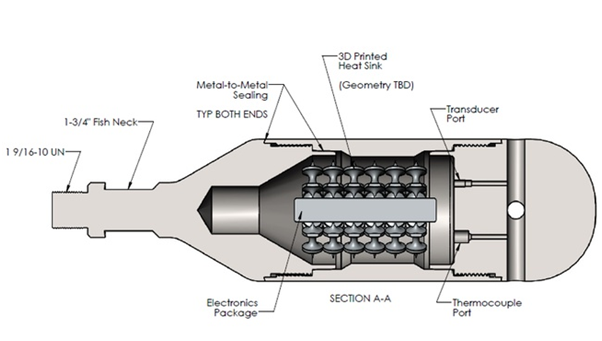

- An ultra high temperature logging tool (see below)

Inflection Point

The DOE competition seeks to accelerate 3D printing such that its geothermal capability matches that of other industrial applications. There’s every reason to think that’s possible: 3D printing has seen major advancements in industries ranging from automotive to aerospace to other clean energy industries with high-grade metal and alloy printing capabilities.

According to Ryan Dehoff, leader of the DOE’s Deposition Science and Technology Group, “Five years ago, the focus was on creating complex geometries. Today additive processes are required to be faster, larger, and use an increased range of materials.”

If other industrial fields with similar needs have reached this inflection point, can geothermal be far behind?

Conclusion

Geothermal is only beginning to embrace 3D printing. Yet the potential rewards are enormous: when a project becomes both technically achievable and affordable, the savings are enormous. The government desperately wants 3D printing to transform geothermal the way it has other tech-heavy industries. 3D printing firms across the country should strongly consider accepting that challenge.