Researchers have developed a novel and highly effective 3D printable system for delivering vaccines to individuals.

In an interview published by Stanford University, Joseph DeSimone describes the new system. By the way, that name might be familiar: he is the founder of Carbon, the well-known manufacturer of high resolution resin 3D printers for industry.

DeSimone is a professor of radiology and chemical engineering, and wanted to determine if there were better ways to deliver vaccines.

Vaccines today are typically administered by a health care worker via a (scary) needle into an arm muscle. From there the vaccine encounters the body’s immune system and begins building resistance to the target virus.

But there are apparently problems with this approach, even though it has been the standard method for decades:

- It ties up a health care worker that could be doing something else that’s more important

- Needles are scary to some and their use dissuades some from getting vaccinated

- The muscle is not the best place to deposit vaccine

That last point is quite interesting, and it’s something I didn’t realize. Apparently the skin includes far more immune cells than muscle, where vaccines are traditionally deposited. DeSimone explains:

“There are 100 to 1,000 times more migratory immune cells in the dermis of the skin than in the muscle. And although the standard practice of injecting the Moderna or Pfizer vaccines for SARS-CoV-2 into someone’s arm muscle is efficient and reliable, those shots go right through the skin and miss most of the immune cells that live there. The vaccine patch enables much more precise delivery to those cells.”

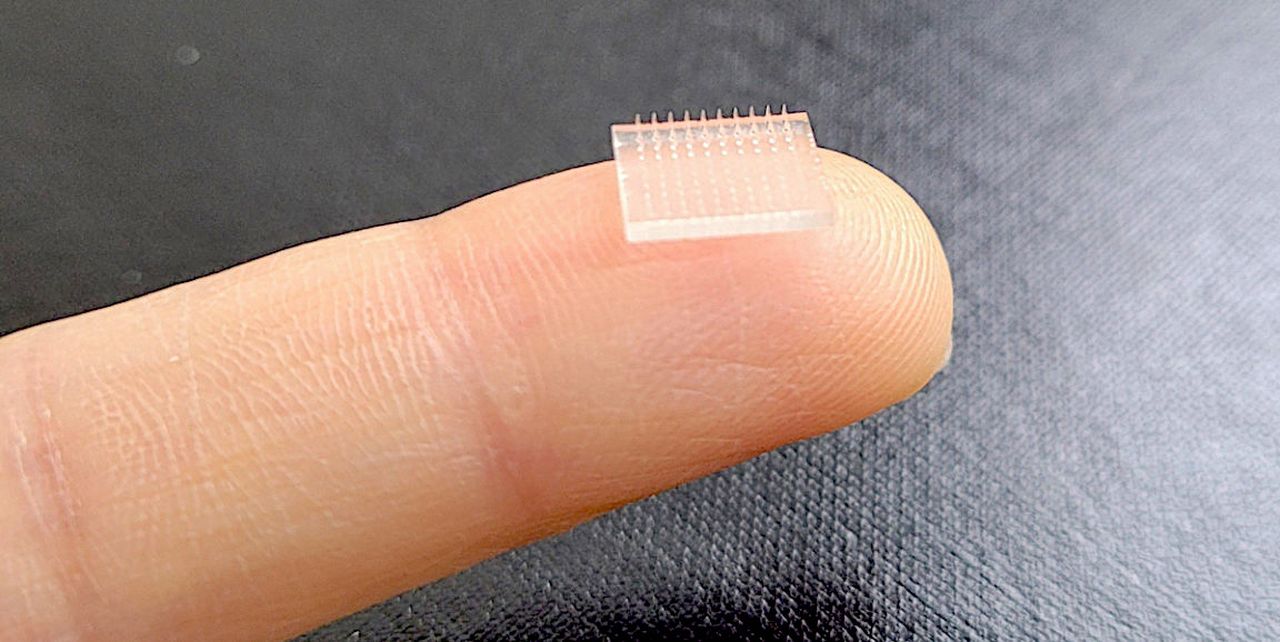

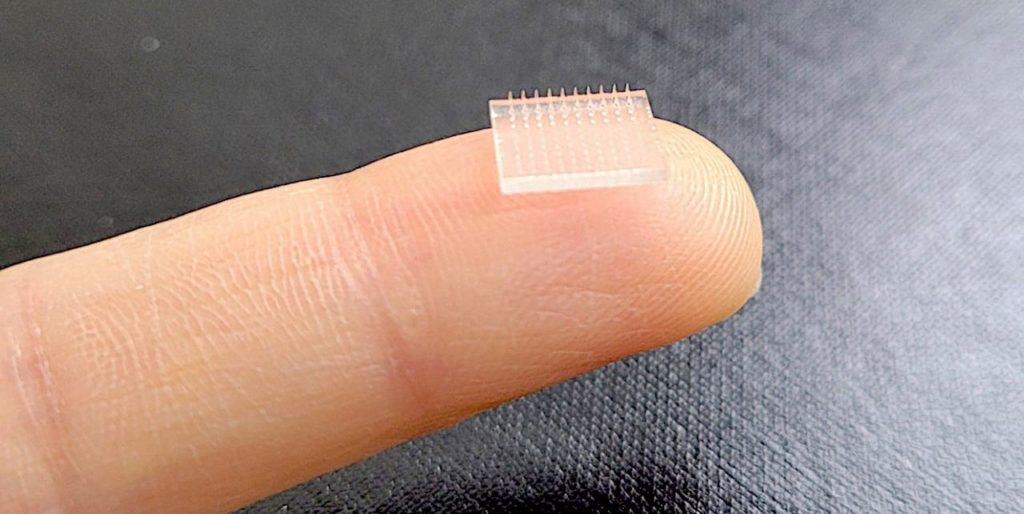

The solution is a complex 3D printed “vaccine patch”. This is a 10 x 10 mm 3D printed square with 100 micro needles on its surface. The patch is dipped in a solution containing the vaccine and then dried. To apply the vaccine, the patient simply pops the patch directly onto the skin where the immune cells are immediately put in contact with the vaccine.

You might be skeptical because the thought of pushing a grid of needles into your skin might be problematic. DeSimone calls this the “bed of nails” problem, but they’ve developed a unique solution. He explains:

“Because they are 3D printed rather than molded, we can do some interesting things to improve how they work. For example, we increase the surface area of the needles by printing faceted rather than smooth needles — meaning they’re shaped almost like thin Christmas trees. Also, when the needles are all the same height, it takes a lot of force to press the patch into the skin, an issue we call the bed-of-nails problem. To address that, we make the microneedles in varying heights.”

The system appears to be highly effective and could be made to be used with a wide variety of vaccine types. The team is apparently developing a SARS-CoV-2 formulation that can be used with the patch system.

If this works, then one could see far easier distribution of vaccines. Imagine dropping into a pharmacy and picking up one and applying it immediately yourself — without any pain.

I could see this technology further developed by pharmaceutical companies: imagine buying a “suite” of annual vaccines in a collection, much like buying a bottle of multivitamins. These patch “packs” could cover common vaccinations that are required repeatedly.

This could become even more interesting as research into MRNA vaccines continues. While we’re all now familiar with the use of MRNA technology to create COVID vaccines, MRNA tech can theoretically be used to create all kinds of interesting vaccines, even against some cancers. I could imagine a future pharmacy being equipped with a pharma 3D printer that might create custom vaccine patches on site based on instructions from medical professionals: a prescription becomes a patch.

It seems that Carbon may have found a new and very large application for their equipment.

Via Stanford (Hat tip to Philip)